Understanding Metal Laser Engravers: Your Ultimate Guide

Metal laser engravers are revolutionizing industries by offering precision, efficiency, and versatility in creating intricate designs on metal surfaces. Whether you’re a hobbyist, an artist, or a business owner, these machines provide a reliable solution for marking, engraving, and cutting metals with exceptional accuracy. This article will explore the world of metal laser engravers, their applications, benefits, and how they can transform your projects. If you’ve ever wondered how to achieve flawless engravings on metal, this guide is for you.

What Are Metal Laser Engravers?

A metal laser engraver is a machine that uses a high-powered laser beam to or intricate designs onto metal surfaces. Unlike traditional methods, which often require manual labor and can be time-consuming, laser engraving offers speed, precision, and consistent results. The process involves directing a focused laser beam at the metal surface, vaporizing or melting the material to create the desired pattern or text.

These machines are widely used in various industries, including jewelry making, automotive manufacturing, electronics, and even custom gifts. They can handle different types of metals, such as steel, aluminum, brass, and stainless steel, making them a versatile tool for many applications. If you’re looking to add a professional touch to your metal projects, understanding how these machines work is essential.

The Technology Behind Metal Laser Engravers

The core of a metal laser engraver lies in its laser technology. Most models use CO2 lasers, which are highly effective for cutting and engraving metals. The laser beam is generated by exciting carbon dioxide gas, producing a high-energy light wave that heats the metal surface to extreme temperatures, causing it to melt or vaporize.

Modern metal laser engravers are equipped with advanced software that allows users to design custom patterns or upload pre-made files. This makes the process user-friendly, even for those without extensive technical skills. The machine then converts the digital design into precise movements of the laser beam, ensuring every detail is captured accurately.

One of the key advantages of CO2 lasers is their ability to work with a wide range of materials, including metal. This versatility makes them an ideal choice for industries that require both engraving and cutting capabilities. If you’re curious about how these machines handle different metal types, read on!

Benefits of Using Metal Laser Engravers

Switching to a metal laser engraver comes with numerous benefits that can elevate your projects to the next level:

- Precision and Accuracy: Laser beams are highly focused, allowing for intricate details and sharp edges in engravings. This is especially important for tasks like creating custom jewelry or electronic components where precision matters most.

- Speed and Efficiency: Unlike traditional methods that require multiple tools and manual adjustments, laser engraving completes tasks quickly, saving time and increasing productivity.

- Versatility: These machines can handle various metal types and thicknesses, making them suitable for a wide range of applications. Whether you’re working on small engravings or large-scale projects, the machine adapts to your needs.

- Durability: Laser-engraved designs are permanent and resistant to wear and tear, ensuring long-lasting results.

If you’re looking for a reliable way to enhance your metalwork, these benefits make metal laser engravers a worthwhile investment. Let’s explore some common applications of these machines in the next section!

Common Applications of Metal Laser Engravers

Metal laser engravers are incredibly versatile and find use in numerous industries. Here are some common applications:

- Jewelry Making: Engraving names, symbols, or intricate patterns on rings, bracelets, and necklaces is a breeze with these machines.

- Custom Gifts: Creating personalized engravings on items like keychains, watches, and plaques adds a unique touch to your products.

- Automotive Industry: Engraving vehicle identification numbers (VINs), logos, or other details on car parts is a common use case.

- Electronics: Marking circuit boards, components, and casings with precise text or patterns is another application of these machines.

If you’re curious about how to choose the right machine for your needs, here’s a guide on selecting the best metal laser engraver for your projects!

How to Choose the Right Metal Laser Engraver

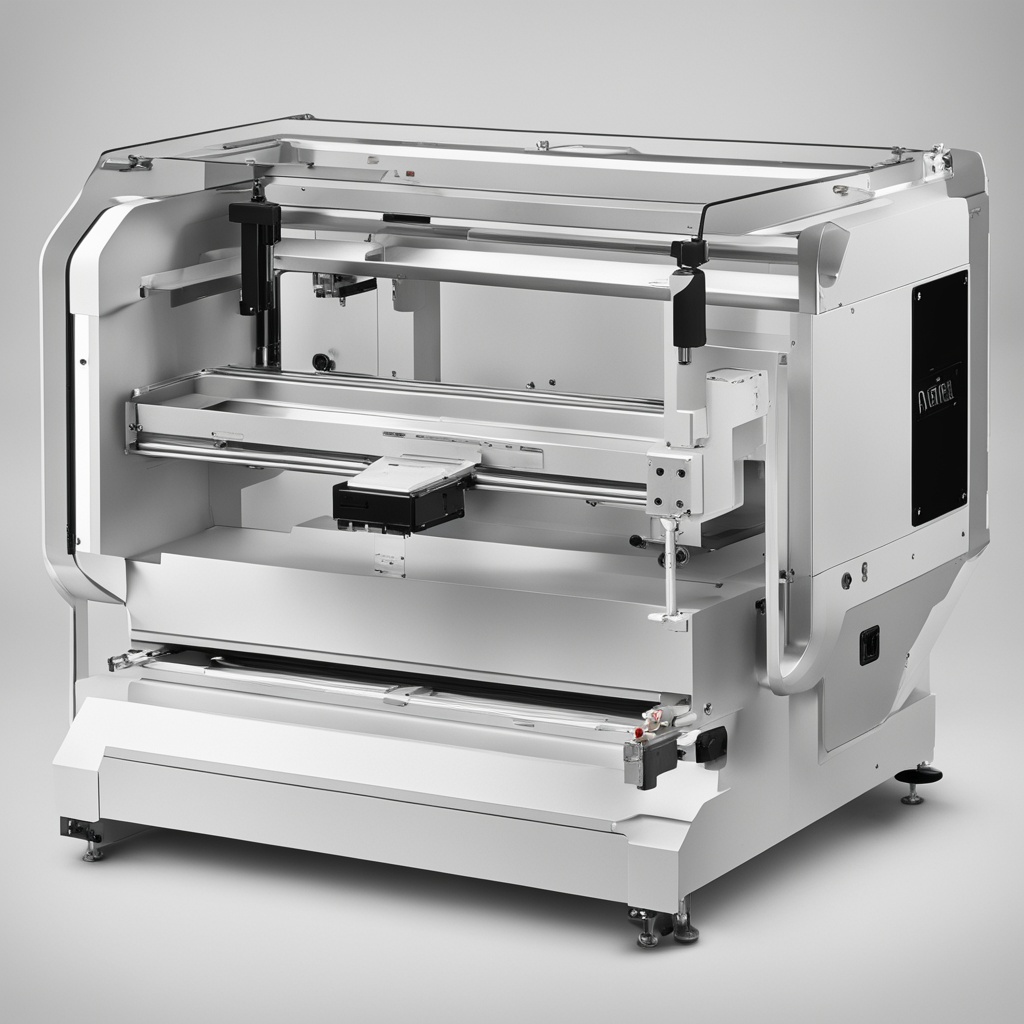

Selecting the perfect metal laser engraver depends on your specific requirements. Here are some factors to consider:

- Laser Power: Higher power lasers are suitable for thicker metals, while lower power machines work better for thinner materials.

- Build Quality: Look for machines with durable components and a stable frame to ensure longevity and precision.

- Software Compatibility: Ensure the machine supports popular design software like CAD or CorelDRAW for ease of use.

- Customer Support: Choose manufacturers that offer excellent customer service and technical support in case you encounter any issues.

By evaluating these factors, you can select a machine that meets your needs and budget. If you’re ready to invest in a metal laser engraver, explore the options available today!

Frequently Asked Questions About Metal Laser Engravers

1. Are metal laser engravers safe to use?

Yes, when used with proper safety precautions, such as wearing protective eyewear and ensuring good ventilation, these machines are safe for both hobbyists and professionals.

2. Can I engrave on all types of metals?

Most metal laser engravers work with common metals like steel, aluminum, and brass. However, some materials may require specific settings or additional precautions.

3. How much do metal laser engravers cost?

The price varies depending on the machine’s power, features, and brand. Entry-level models can start at a few hundred dollars, while high-end industrial machines can cost thousands of dollars.

4. Do I need special training to operate a metal laser engraver?

While some technical knowledge is helpful, many machines come with user-friendly interfaces and software that make them accessible even for beginners.

Conclusion

Metal laser engravers are powerful tools that offer precision, versatility, and efficiency in creating intricate designs on metal surfaces. Whether you’re a hobbyist or a business owner, these machines can transform your projects into works of art. By understanding how they work, their benefits, and how to choose the right one, you can take your metalwork to new heights.

If you’re ready to invest in a metal laser engraver, explore the options available today and start creating stunning engravings like never before! Your next project could be just a few clicks away.