The Ultimate Guide to Laser Cutters for Fabric: Everything You Need to Know

Are you searching for a precise and efficient way to cut fabric? Look no further than the laser cutter for fabric. This innovative tool has revolutionized the textile industry, offering unparalleled accuracy and versatility. In this comprehensive guide, we’ll explore everything you need to know about laser cutters for fabric, including their benefits, applications, and how they work. Whether you’re a seasoned professional or just starting out, this article will provide valuable insights to help you make an informed decision.

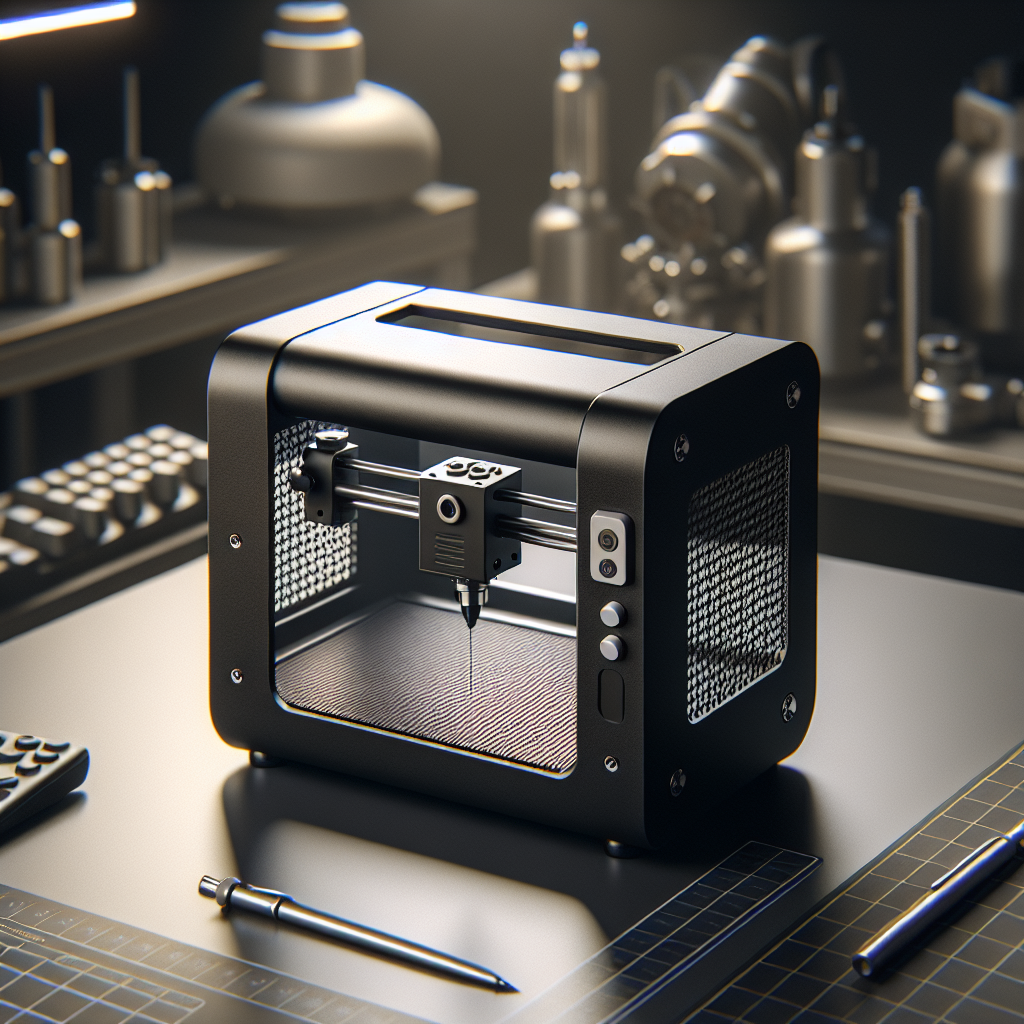

What is a Laser Cutter for Fabric?

A laser cutter for fabric is a machine that uses a high-powered laser beam to cut through various types of materials, including fabrics. Unlike traditional cutting methods that rely on blades or scissors, laser cutting offers unmatched precision and efficiency. The process involves directing the laser beam at the material, which heats and vaporizes it, creating clean and seamless cuts.

One of the key advantages of a laser cutter for fabric is its ability to handle delicate materials without causing damage. This makes it an ideal choice for cutting thin fabrics like silk or satin, as well as thicker materials like denim or canvas. Additionally, laser cutters can create intricate designs and patterns that would be difficult or time-consuming to achieve with manual methods.

Benefits of Using a Laser Cutter for Fabric

There are numerous benefits to using a laser cutter for fabric, especially for businesses in the textile industry. Here are some of the most notable advantages:

- Precision and Accuracy: Laser cutters produce clean, precise cuts with minimal tolerance, ensuring consistent results every time.

- Speed and Efficiency: Compared to manual cutting methods, laser cutters are much faster, reducing production time and increasing output.

- Versatility: Laser cutters can handle a wide range of materials, including fabrics, leather, paper, and more.

- Reduced Waste: The precision of laser cutting minimizes material waste, making it an eco-friendly option for manufacturers.

- Cost-Effective: While the initial investment may seem high, laser cutters can save money in the long run by reducing labor costs and minimizing waste.

How Does a Laser Cutter Work?

Understanding how a laser cutter for fabric works is essential for appreciating its capabilities. The process involves several key components:

- Laser Source: The laser beam is generated by a laser source, which can be either CO2 or fiber-based, depending on the application.

- Optics and Mirrors: The laser beam is directed through optics and mirrors to focus it onto the material being cut.

- Focusing Lens: A focusing lens concentrates the laser beam into a small, intense spot, creating the heat necessary for cutting.

- Motion System: The motion system moves the laser head or the material to create the desired cuts and patterns.

The laser beam heats the material to its melting or vaporization point, effectively cutting through it without requiring physical contact. This non-contact method ensures minimal damage to the surrounding material, making it ideal for delicate fabrics.

Applications of Laser Cutters in Fabric Cutting

Laser cutters are incredibly versatile and can be used in a wide range of applications within the textile industry. Some common uses include:

- Clothing Production: Laser cutters are used to create intricate designs, appliqués, and decorative elements for clothing.

- Home Decor: From curtains to upholstery, laser cutters can produce precise cuts for home decor items.

- Fabric Accessories: Items like scarves, tote bags, and fabric jewelry can be efficiently produced using laser cutting technology.

- Custom Prints: Laser cutters can be used to create custom prints and patterns on fabric surfaces.

Factors to Consider When Purchasing a Laser Cutter for Fabric

If you’re considering investing in a laser cutter for fabric, there are several factors to keep in mind:

- Budget: Determine your budget and compare the costs of different models, keeping in mind the long-term savings they can provide.

- Material Thickness: Consider the types of fabrics you’ll be cutting and ensure the laser cutter is capable of handling their thickness.

- Software Compatibility: Check if the laser cutter is compatible with your existing design software or if additional software is required.

- Maintenance: Regular maintenance is essential for keeping your laser cutter in optimal condition. Factor in the cost of replacement parts and servicing.

Frequently Asked Questions About Laser Cutters for Fabric

Here are some common questions people ask about laser cutters for fabric:

- Q: Can a laser cutter be used on all types of fabrics?

A: While laser cutters can handle most fabrics, they may not work well with materials that reflect or absorb laser light, such as metallic fabrics.

- Q: Is it safe to use a laser cutter?

A: Yes, but safety precautions must be taken. Always wear protective eyewear and ensure proper ventilation to avoid inhaling fumes generated during cutting.

- Q: How much does a laser cutter cost?

A: The cost of a laser cutter varies depending on its size, power, and features. Entry-level models can range from $10,000 to $50,000 or more.

The Future of Laser Cutting in the Textile Industry

As technology continues to advance, laser cutters for fabric are likely to become even more sophisticated and accessible. Innovations such as AI-driven cutting systems and eco-friendly laser technologies are already making waves in the industry, offering new possibilities for manufacturers.

If you’re looking to upgrade your textile production process or start a fabric-based business, investing in a laser cutter could be the best decision you make. With its precision, versatility, and efficiency, it’s no wonder that laser cutting has become a cornerstone of modern textile manufacturing.

Ready to take the plunge? Check out our top recommendations for and find the perfect tool for your needs!