The Ultimate Guide to CNC Laser Cutters

CNC laser cutters are revolutionizing industries by offering precision, efficiency, and versatility in cutting and engraving materials. If you’re exploring this technology, you might be wondering how it works, its applications, and whether it’s the right choice for your needs. In this comprehensive guide, we’ll dive into everything you need to know about , their benefits, and how they can transform your projects. Let’s get started!

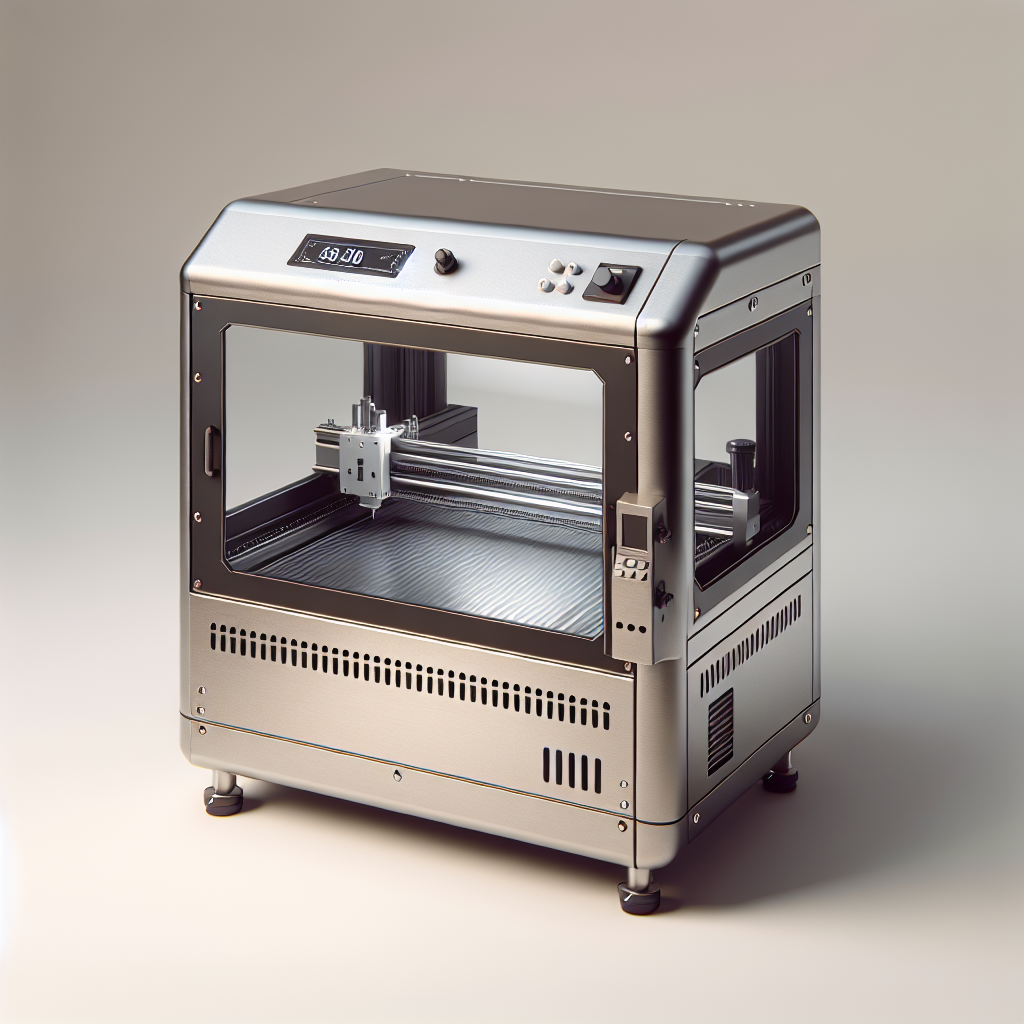

What is a CNC Laser Cutter?

A CNC laser cutter is a cutting-edge machine that uses computer numerical control (CNC) to guide a high-powered laser beam for precise cutting, engraving, or marking of various materials. Unlike traditional cutting methods, this technology offers unparalleled accuracy and flexibility. It’s widely used in industries such as manufacturing, jewelry making, sign making, and more.

The machine works by converting digital designs into physical products. The CNC system reads the design file and directs the laser beam to follow the specified pattern. This process is not only fast but also highly accurate, ensuring minimal material waste and superior quality output.

Applications of CNC Laser Cutters

CNC laser cutters are incredibly versatile and can work with a wide range of materials, including metal, wood, plastic, glass, and stone. Here are some common applications:

- Metal Cutting: Ideal for shaping metals like steel, stainless steel, and aluminum for industrial or decorative purposes.

- Woodworking: Used to create intricate designs, furniture parts, and decorative items.

- Jewelry Making: Perfect for engraving and cutting precious metals and gemstones with precision.

- Signage Production: Creates custom signs, logos, and lettering with sharp edges and clean finishes.

If you’re wondering, “What industries can benefit the most from CNC laser cutters?” The answer is almost any industry that requires precise cutting or engraving. From automotive to architecture, these machines are transforming workflows across sectors.

Advantages of Using a CNC Laser Cutter

Switching to a CNC laser cutter comes with numerous benefits:

- High Precision: The laser beam ensures accurate cuts, even in complex designs.

- Speed and Efficiency: Processes are faster than traditional methods, reducing production time.

- Versatility: Works with multiple materials and can handle both small and large-scale projects.

- Minimal Waste: Precise cuts reduce material waste, lowering costs over time.

If you’re considering investing in a CNC laser cutter, these advantages should make the decision easier. However, it’s essential to evaluate your specific needs before making a purchase.

Key Considerations When Choosing a CNC Laser Cutter

Before purchasing a CNC laser cutter, there are several factors to consider:

- Laser Power: Higher power lasers can cut through thicker materials but may require more energy.

- Cutting Speed: Determine the desired processing speed based on your project volume.

- Material Compatibility: Ensure the machine can handle the types of materials you’ll be working with.

- Budget: CNC laser cutters vary in price, so set a budget and look for features that align with your needs.

If you’re asking yourself, “Which CNC laser cutter is right for my business?” it’s crucial to evaluate these factors carefully. For instance, if you’re working primarily with metals, you might want a machine specifically designed for metal cutting.

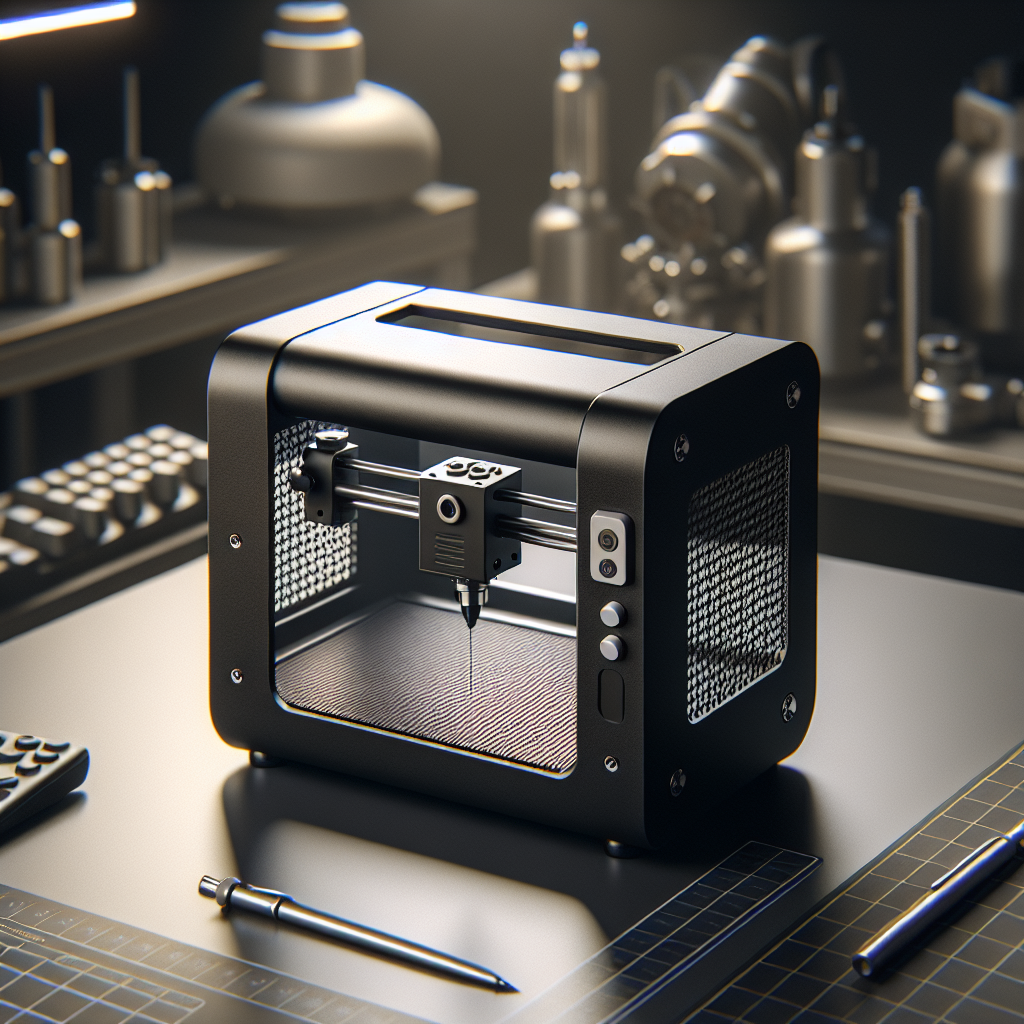

How to Get Started with a CNC Laser Cutter

Once you’ve selected the right machine, getting started is straightforward:

- Design Your Project: Use CAD software to create your digital design.

- Set Up the Machine: Prepare the materials and ensure the laser settings are correct for your project.

- Run the Job: Upload your design to the CNC system and let the machine do the work!

If you’re new to CNC laser cutting, don’t worry. Most machines come with user-friendly interfaces and manuals to guide you through the process. Additionally, there are numerous online tutorials available to help you master this technology.

Frequently Asked Questions About CNC Laser Cutters

Here are some common questions people have about CNC laser cutters:

- Q: Can a CNC laser cutter work with all materials?

A: While they can handle many materials, compatibility depends on the machine’s specifications and the type of laser used. - Q: How much does a CNC laser cutter cost?

A: Prices vary widely depending on power, features, and brand. Entry-level machines start around $10,000, while high-end models can exceed $100,000. - Q: Is maintenance required for CNC laser cutters?

A: Yes, regular maintenance is essential to ensure optimal performance and longevity of the machine.

If you’re still unsure about whether a CNC laser cutter is right for your needs, consider reaching out to industry experts or testing the machine with sample materials before making a purchase.

Conclusion

CNC laser cutters are powerful tools that can elevate your projects to new heights. Their precision, versatility, and efficiency make them an invaluable addition to any workshop or manufacturing facility. If you’re ready to take the plunge, consider exploring options like the mentioned earlier.

Remember, investing in quality equipment is key to long-term success. Take your time to research and choose the right CNC laser cutter for your needs, and watch as your projects come to life with exceptional precision and detail!