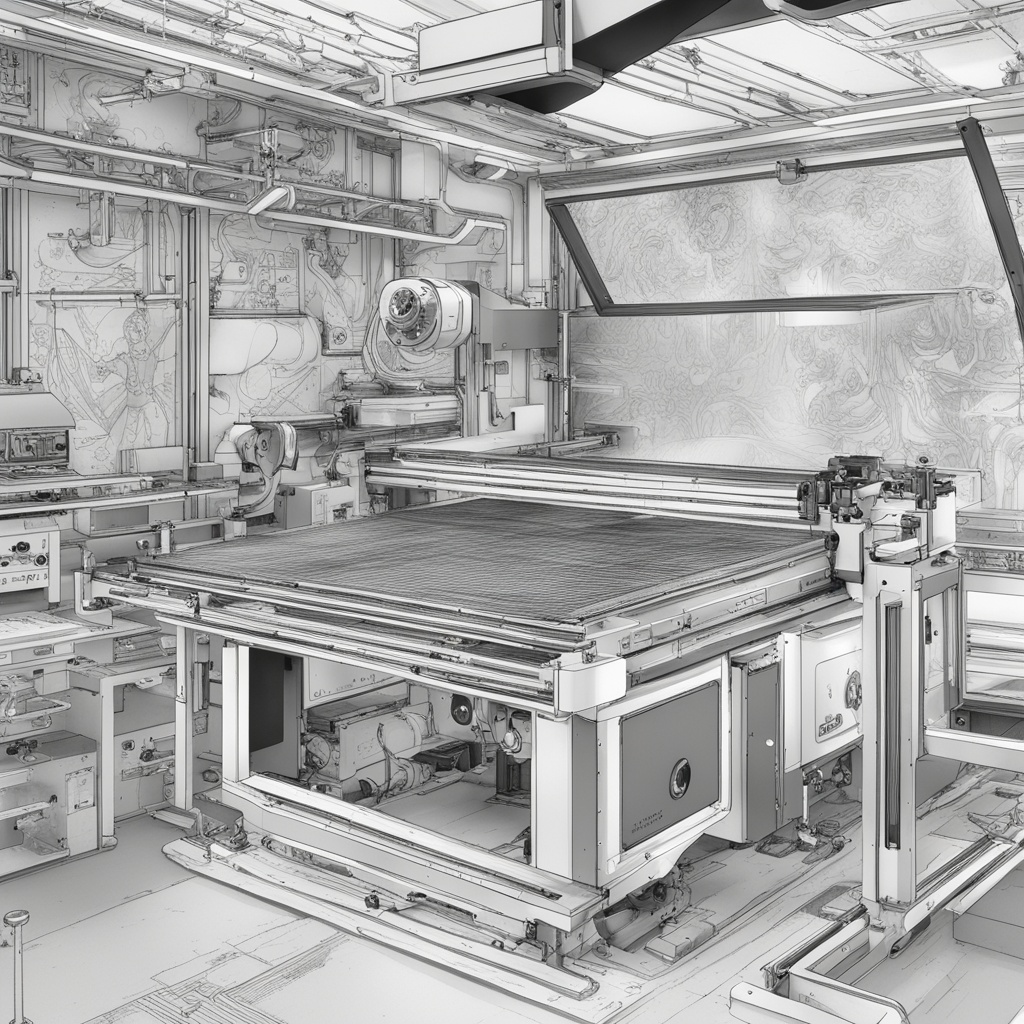

The Rise of Precision: Exploring the Power of daja laser engraver Technology

In the ever-evolving world of manufacturing and creative design, laser engraving machines have emerged as indispensable tools. Among these, the daja laser engraver stands out as a game-changer, combining affordability, precision, and versatility. Whether you’re a small business owner, a hobbyist, or an industrial designer, understanding the capabilities of a daja laser engraver can unlock new opportunities for innovation.

What Makes daja laser engraver Machines Unique?

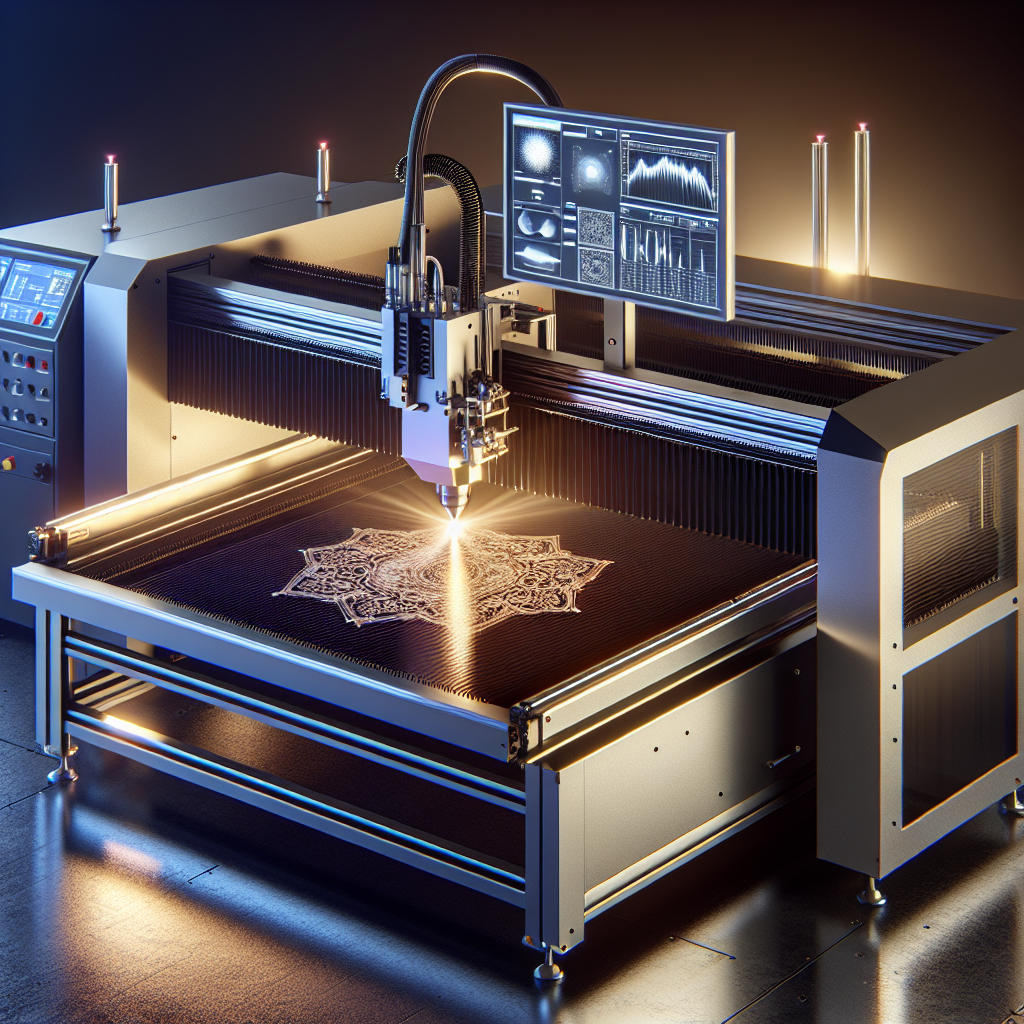

The daja laser engraver series is engineered to deliver high-performance results without the hefty price tag. Unlike traditional engraving methods, these machines use focused laser beams to etch designs onto materials like wood, metal, glass, and acrylic. What sets them apart? Here are some key features:

- Precision Control: Advanced software ensures micron-level accuracy, perfect for intricate designs.

- Cost-Effective: Reduced energy consumption and minimal material waste lower operational costs.

- Multi-Material Compatibility: From leather to ceramics, the daja laser engraver handles diverse substrates effortlessly.

- User-Friendly Interface: Intuitive controls make it accessible for beginners and experts alike.

Applications of daja laser engraver Systems

Why invest in a daja laser engraver? The answer lies in its broad applicability. Below are industries where this technology shines:

- Personalized Gifts: Engrave names, dates, or custom artwork on jewelry, phone cases, and photo frames.

- Industrial Marking: Permanent serial numbers, logos, or barcodes on machinery parts.

- Art and Decor: Create detailed wall art, signage, or architectural models.

- Fashion and Textiles: Etch patterns on fabrics or leather goods.

Did you know? The daja laser engraver is also used in aerospace for marking components with strict durability requirements.

Why Choose daja laser engraver Over Competitors?

With so many laser engravers on the market, the daja laser engraver distinguishes itself through innovative engineering and customer-centric design. Here’s why professionals prefer it:

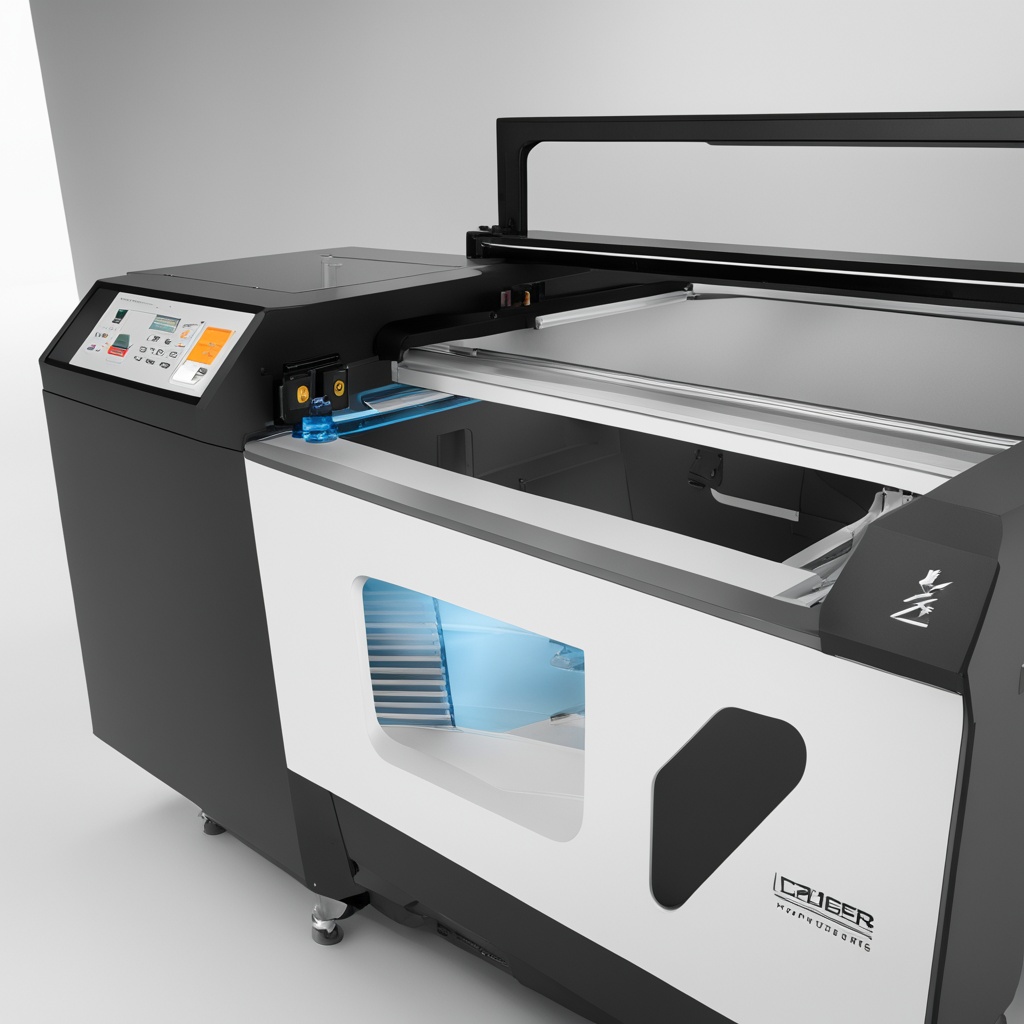

- Speed and Efficiency: Faster processing times without compromising quality.

- Low Maintenance: Built with durable components that reduce downtime.

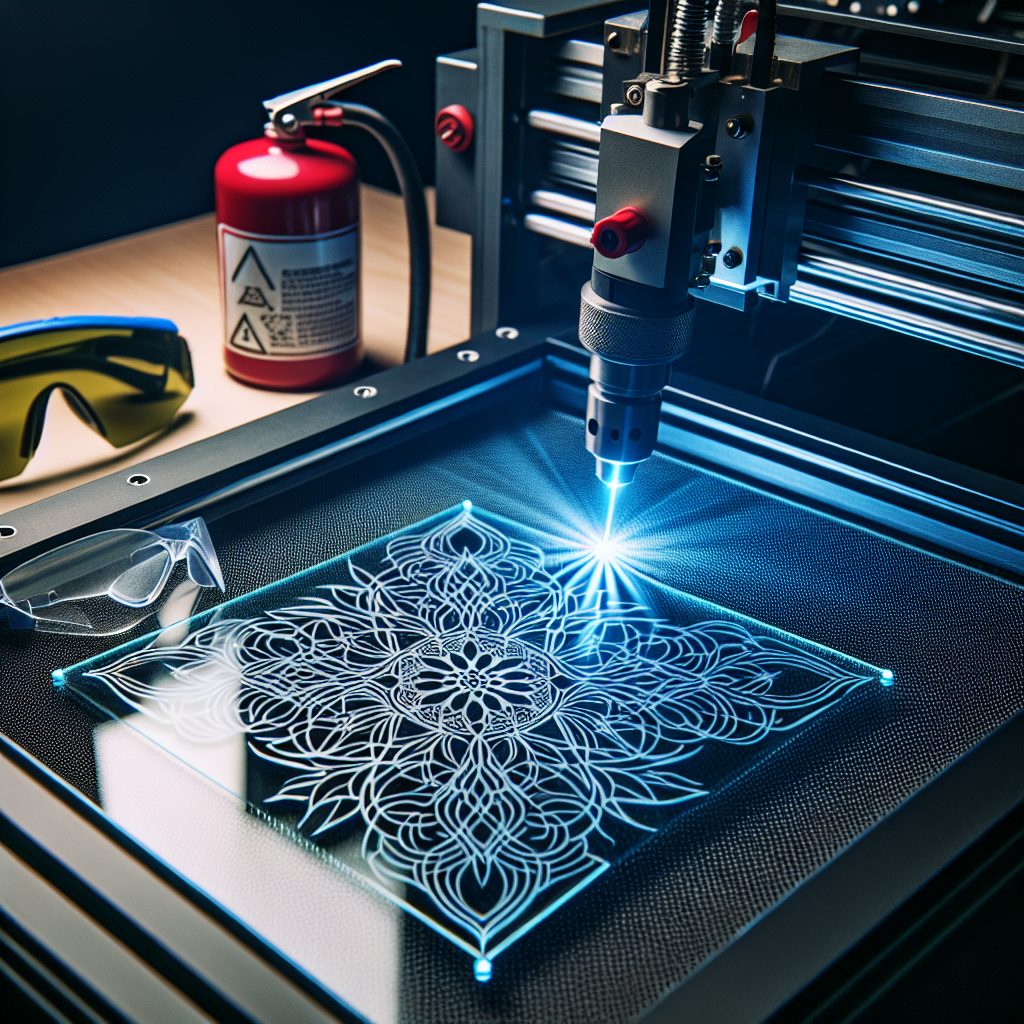

- Safety Features: Automatic shut-off mechanisms and protective enclosures.

- Scalability: Suitable for both small workshops and large-scale production lines.

Question: How does the daja laser engraver handle heat-sensitive materials? Its adjustable power settings prevent overheating, ensuring clean cuts on delicate substrates.

Key Considerations Before Buying a daja laser engraver

Investing in a laser engraver requires careful planning. Ask yourself:

- What materials will I work with? Ensure the machine supports your primary substrates.

- What’s my budget? The daja laser engraver offers a balance between cost and performance.

- Do I need portability? Compact models are ideal for mobile businesses.

- What software compatibility is required? Check if it integrates with your design tools.

Pro Tip: Always request a demo or sample engraving to test the machine’s capabilities firsthand.

Maintenance Tips for Longevity

To maximize the lifespan of your daja laser engraver, follow these best practices:

- Clean lenses and mirrors regularly to prevent dust buildup.

- Lubricate moving parts as per the manufacturer’s guidelines.

- Update software to access the latest features and security patches.

- Store the machine in a dry, temperature-controlled environment.

Warning: Neglecting maintenance can lead to reduced accuracy and costly repairs.

Frequently Asked Questions

Q: Can a daja laser engraver cut through metal?

A: Yes, but this depends on the laser’s power. Higher-wattage models can engrave and cut thin metals.

Q: Is specialized training required to operate the machine?

A: Basic training is recommended, but the intuitive interface simplifies the learning curve.

Q: How does the daja laser engraver compare to CNC routers?

A: Laser engravers excel in precision and speed for detailed designs, while CNC routers are better for heavy-duty cutting.

The Future of Laser Engraving Technology

As industries demand faster, greener, and more customizable solutions, the daja laser engraver is poised to lead the charge. Innovations like AI-driven design automation and eco-friendly lasers are on the horizon. Question: Will these advancements make laser engraving accessible to even more users? Absolutely—by lowering costs and simplifying workflows.

Final Thoughts

Whether you’re crafting personalized gifts or industrial components, the daja laser engraver offers unmatched versatility and reliability. By understanding its features, applications, and maintenance needs, you can harness its full potential. Ready to transform your creative or manufacturing process? Explore how this cutting-edge tool can elevate your projects today.