The Comprehensive Guide to CO2 Laser Engraving Machines: Precision, Versatility, and Innovation

In the realm of modern manufacturing and creative craftsmanship, laser engraver CO2 systems have emerged as indispensable tools. These machines combine advanced technology with unparalleled precision, enabling users to engrave, cut, and mark a vast array of materials. Whether you’re a hobbyist, a small business owner, or an industrial manufacturer, understanding the capabilities of CO2 laser engravers is essential for optimizing productivity and creativity. This article dives deep into the mechanics, applications, and advantages of laser engraver CO2 systems while addressing common questions and considerations.

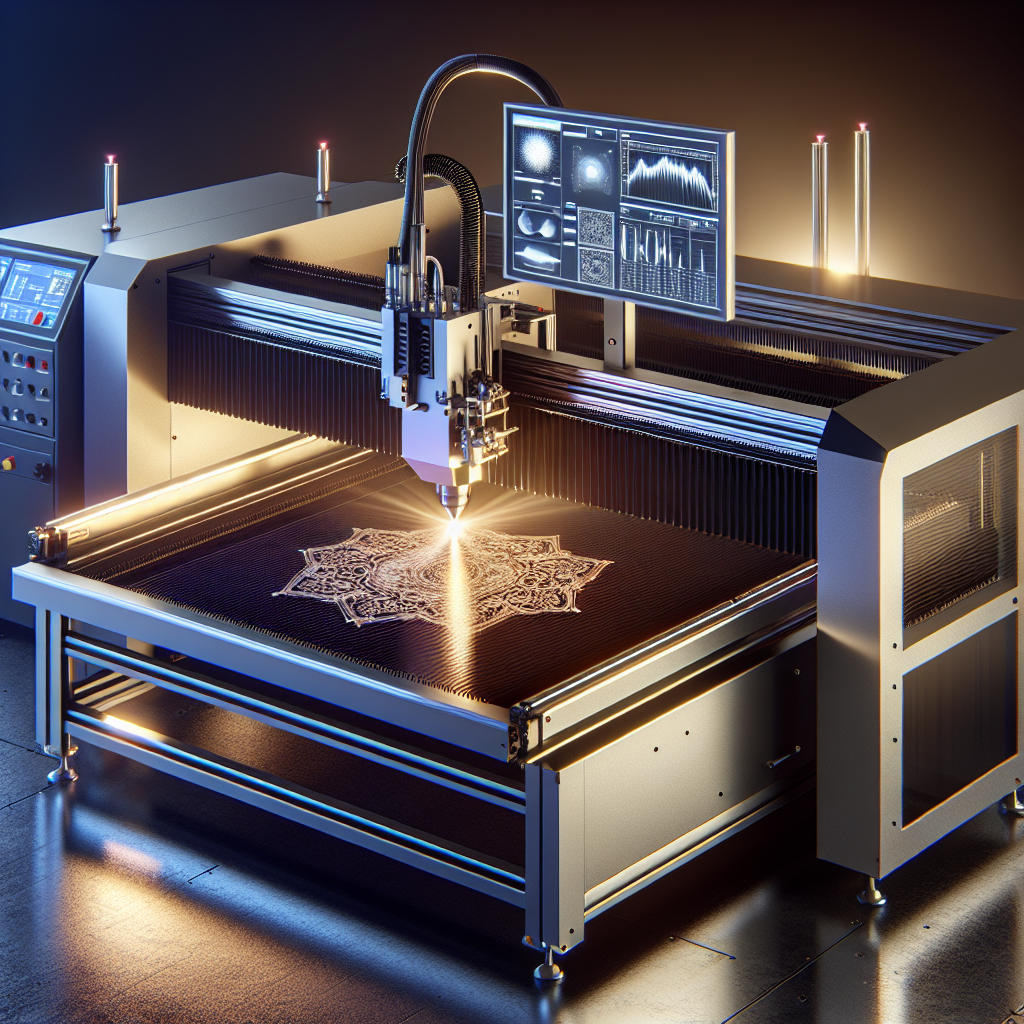

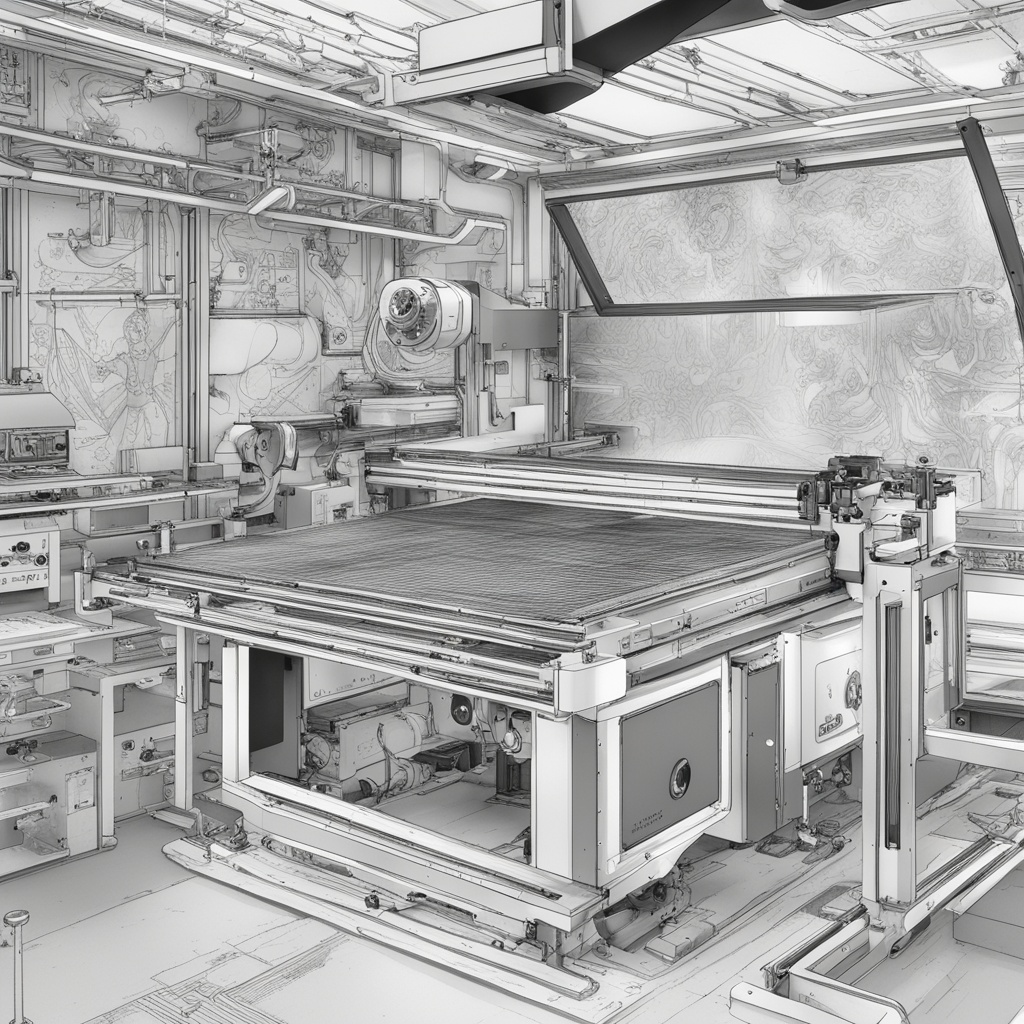

How Do CO2 Laser Engraving Machines Work?

At the core of every laser engraver CO2 is a gas-filled tube that generates a high-intensity laser beam. This beam, produced by exciting carbon dioxide molecules, is directed through mirrors and focused onto the material’s surface via a lens. The concentrated heat vaporizes or burns the material, creating precise engravings or cuts. What sets CO2 lasers apart is their wavelength (typically 10.6 micrometers), which is ideal for processing non-metallic materials like wood, acrylic, leather, glass, and plastics.

Key Advantages of CO2 Laser Engravers

Why choose a laser engraver CO2 over other laser types? Here’s a breakdown of their unique benefits:

- Material Versatility: CO2 lasers excel at engraving organic materials, fabrics, and polymers, making them ideal for diverse industries.

- High Precision: With resolutions up to 1000 DPI, these machines produce intricate designs with razor-sharp edges.

- Speed and Efficiency: Advanced systems can complete complex projects in minutes, boosting production throughput.

- Low Maintenance: Unlike fiber lasers, CO2 systems require minimal upkeep beyond routine lens cleaning and gas refills.

Applications of CO2 Laser Engraving Machines

The adaptability of laser engraver CO2 technology unlocks endless possibilities. Below are some popular use cases:

- Personalized Gifts: Engrave names, dates, or artwork on wood, glass, or acrylic keepsakes.

- Industrial Marking: Permanently label serial numbers, barcodes, or logos on packaging and components.

- Textile and Fashion: Cut intricate patterns for fabrics or etch designs onto leather accessories.

- Architectural Models: Create detailed prototypes from materials like MDF or acrylic sheets.

Did you know? Some laser engraver CO2 models can even process anodized metals when paired with specialized coatings!

Choosing the Right CO2 Laser Engraver for Your Needs

Selecting the perfect laser engraver CO2 requires careful evaluation of your goals. Ask yourself:

- What materials will I primarily work with? Ensure the machine’s power (measured in watts) matches your material’s thickness and density.

- What is my budget? Entry-level models start around $3,000, while industrial-grade systems can exceed $20,000.

- Do I need additional features? Consider upgrades like rotary attachments for cylindrical objects or dual-laser compatibility.

For example, the LaserHawk LX1 (available here) is a versatile laser engraver CO2 designed for both metal and non-metal applications, making it a favorite among small businesses.

Maintenance Tips for Longevity

To maximize the lifespan of your laser engraver CO2, follow these best practices:

- Clean lenses and mirrors weekly using isopropyl alcohol to prevent residue buildup.

- Check the gas tube pressure monthly and refill as needed.

- Calibrate the laser focus regularly to maintain precision.

- Use air assist systems to minimize smoke damage during cutting.

Pro Tip: Always power down the machine before performing maintenance to avoid accidental laser activation.

Common Questions About CO2 Laser Engravers

Q: Can CO2 lasers engrave metals?

A: While CO2 lasers are optimized for non-metals, some models can mark coated metals or anodized surfaces. For bare metals, fiber lasers are more effective.

Q: How much power do I need for cutting 1/4-inch acrylic?

A: A 40W-60W laser engraver CO2 is sufficient for thin materials, but thicker cuts may require 80W-100W systems.

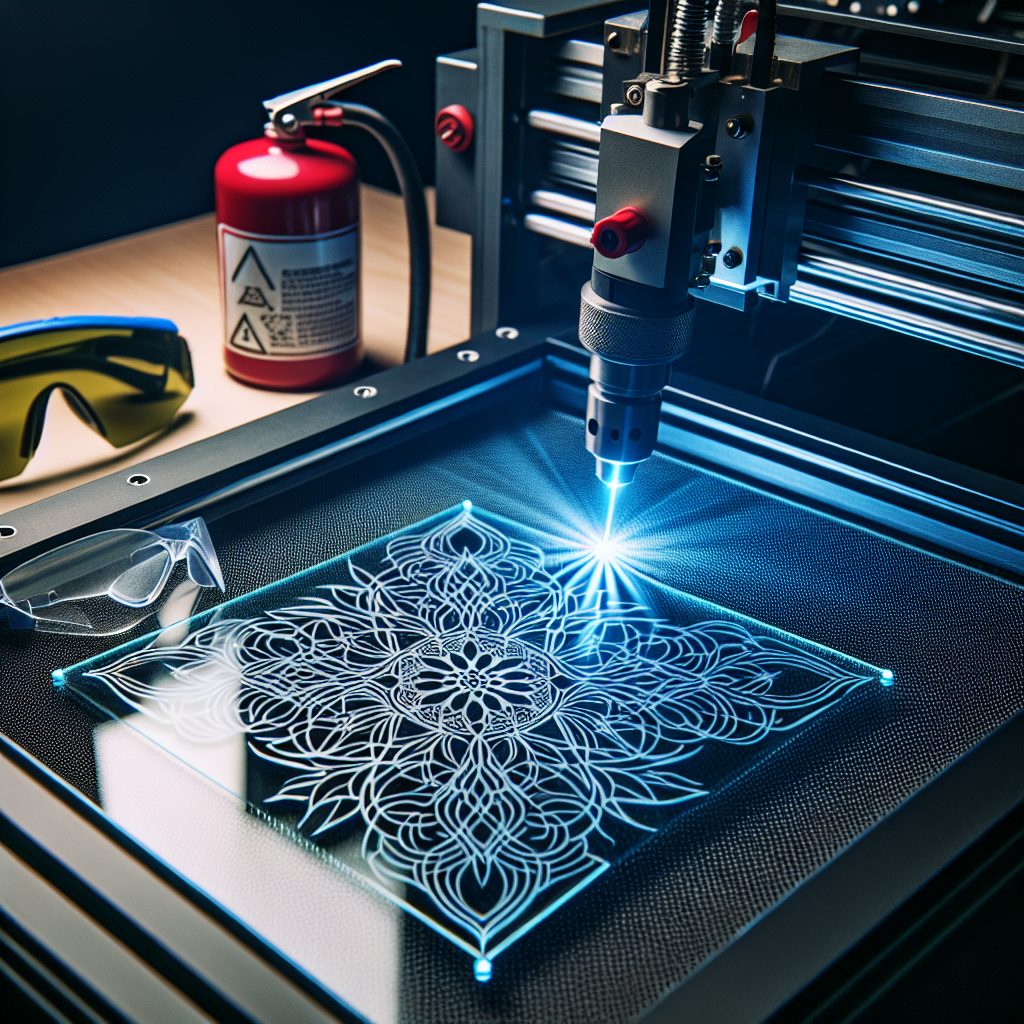

Q: Are CO2 lasers safe to use indoors?

A: Yes, provided the machine has proper ventilation to remove toxic fumes. Always follow safety guidelines and wear protective eyewear.

Future Trends in CO2 Laser Technology

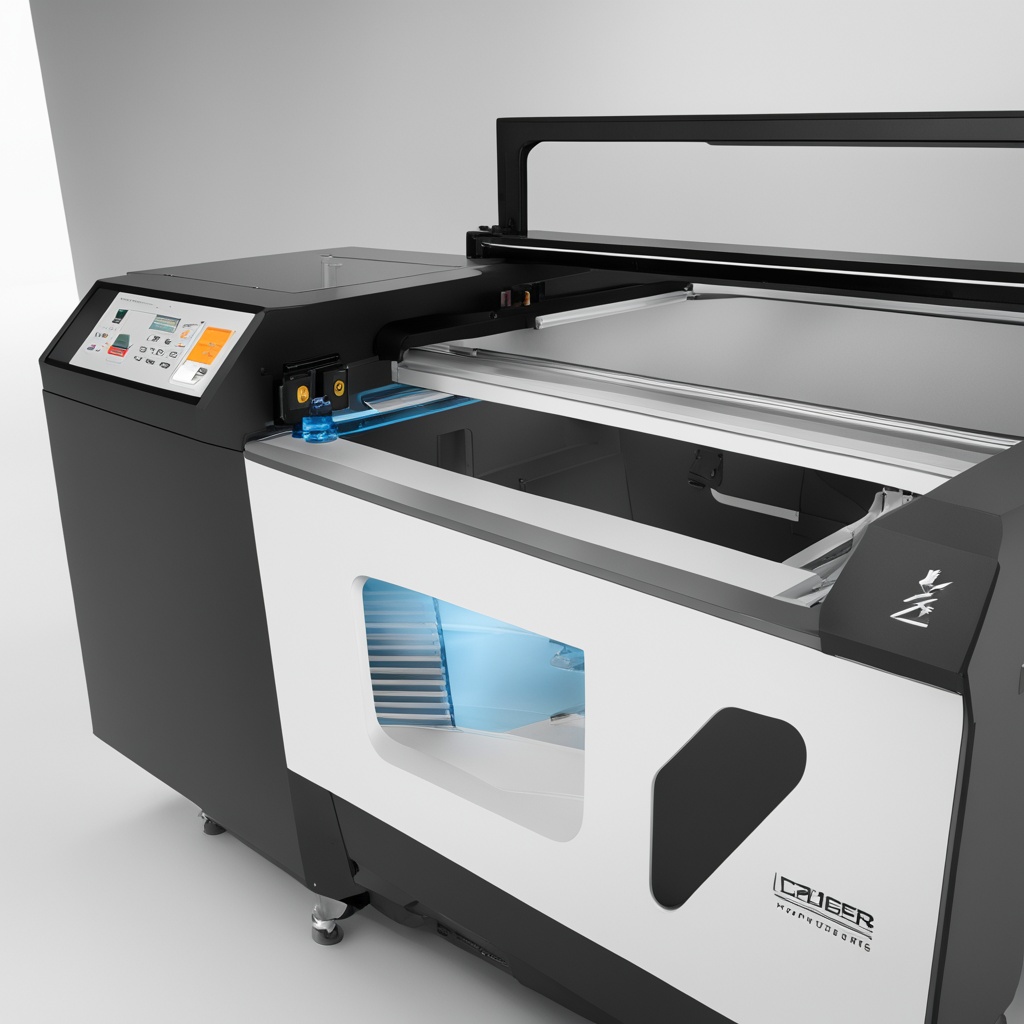

The evolution of laser engraver CO2 systems continues to accelerate. Innovations like AI-driven design software, hybrid laser systems (combining CO2 and fiber lasers), and IoT-enabled remote monitoring are reshaping the industry. Manufacturers are also prioritizing energy efficiency, with newer models consuming 30% less power than traditional units.

Conclusion: Why Invest in a CO2 Laser Engraver?

From personalized crafts to industrial-scale production, a laser engraver CO2 offers unmatched flexibility and precision. By understanding its capabilities, maintenance needs, and ideal applications, you can unlock new levels of creativity and efficiency. Ready to explore your options? Check out the LaserHawk LX1 here to see how a professional-grade CO2 laser can transform your projects.

Final Question: How will integrating a laser engraver CO2 into your workflow elevate your business or creative endeavors?