Exploring the World of Local Laser Engraving: Benefits and Applications

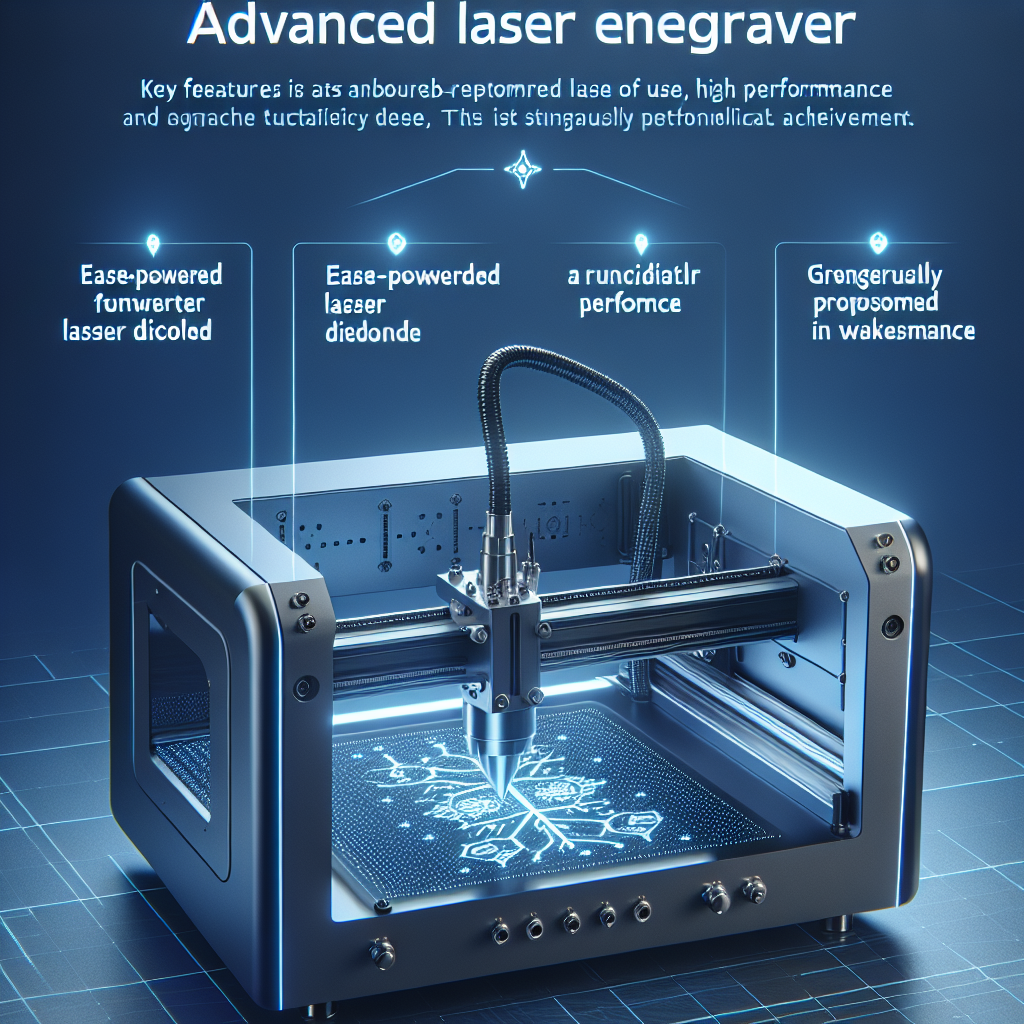

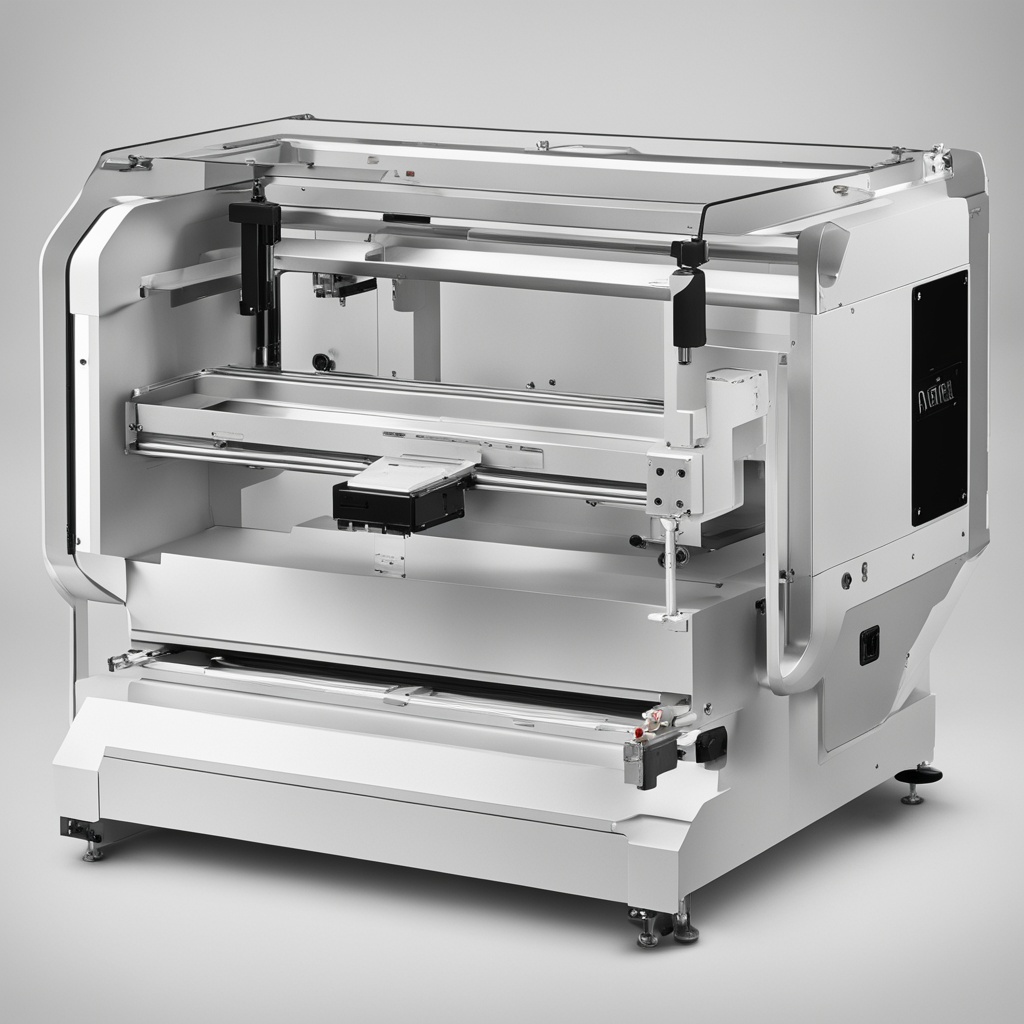

Local laser engraving has revolutionized the way we personalize and customize products, offering precision and creativity that traditional methods simply can’t match. With advancements in technology, devices like the machine have become accessible to both professionals and hobbyists alike. This article delves into the benefits, applications, and considerations of local laser engraving, providing a comprehensive guide for anyone looking to explore this innovative field.

The Benefits of Local Laser Engraving

Laser engraving offers numerous advantages over traditional methods. One of the most significant benefits is the ability to achieve intricate designs with unmatched precision. Whether you’re working on metal, wood, or glass, laser engraving ensures that every detail is captured accurately. This level of precision is particularly valuable in industries where exactness is crucial, such as jewelry making or industrial manufacturing.

Another key advantage is the versatility of local laser engraving machines. They can handle a wide range of materials, from metals like stainless steel and aluminum to delicate surfaces like glass. This adaptability makes them suitable for various applications, including creating custom signage, promotional items, and personalized gifts.

- High precision for intricate designs

- Versatility in material handling

- Cost-effective for small-scale projects

- Minimal setup time compared to traditional methods

Moreover, local laser engraving is often more cost-effective, especially for small-scale projects. Unlike traditional engraving methods that may require expensive molds or tools, laser engravers can switch between designs with just a few clicks, reducing both time and material costs.

How Local Laser Engraving Works

To understand the process better, let’s break down how local laser engraving works. The machine uses a focused beam of light to vaporize or burn away material, creating a design or pattern on the surface. This method is not only precise but also non-contact, minimizing the risk of damage to the material being engraved.

The process typically involves several steps:

- Design creation using specialized software

- Loading the material into the engraving machine

- Selecting the appropriate settings for the material type and desired depth

- Starting the engraving process and monitoring it until completion

One of the standout features of the machine is its user-friendly interface, making it accessible even for those new to laser engraving.

Applications of Local Laser Engraving

The applications of local laser engraving are vast and varied. From creating custom jewelry with intricate patterns to producing promotional items like engraved pens or keychains, the possibilities are endless. The automotive industry also benefits from laser engraving for producing precise parts and components.

One question that often arises is: “What materials can be used with a local laser engraver?” The answer lies in the adaptability of these machines. They can work on metals, woods, plastics, glass, and even some fabrics, making them suitable for diverse industries such as:

- Jewelry design

- Signage production

- Custom gifts

- Automotive manufacturing

In the field of electronics, laser engraving is used to create circuit boards with high precision. This application underscores the importance of local laser engraving in modern technology.

Maintenance and Safety Tips for Local Laser Engravers

While local laser engraving machines are robust, proper maintenance is essential to ensure optimal performance and longevity. Regular cleaning of the machine’s optics and lenses is crucial to prevent dust buildup, which can affect engraving accuracy.

Safety should always be a priority when operating a laser engraver. Always wear protective eyewear and ensure adequate ventilation in your workspace to avoid inhaling any fumes produced during the engraving process.

Frequently Asked Questions About Local Laser Engraving

Here are answers to some common questions:

- What materials can I engrave with a local laser machine? Metals, woods, plastics, glass, and certain fabrics.

- How easy is it to learn how to use a local laser engraver? Most machines come with intuitive software and user guides, making them accessible for beginners.

- Can I switch between different materials easily? Yes, by adjusting the machine settings according to the material type and desired outcome.

Conclusion

Local laser engraving has emerged as a powerful tool in modern manufacturing and customization. Its precision, versatility, and adaptability make it indispensable across various industries. Whether you’re creating personalized gifts or producing complex industrial components, understanding how to harness the capabilities of local laser engravers can open up endless possibilities.

As technology continues to evolve, so too will the applications of local laser engraving. Embracing this innovation can provide a competitive edge in both creative and industrial settings. So why wait? Explore the world of local laser engraving today and unlock your full potential!