Exploring the Plastic Laser Cutter Handheld: A Comprehensive Guide

When it comes to precision cutting and engraving, few tools can match the versatility and efficiency of a plastic laser cutter handheld. Whether you’re working on small-scale projects or need precise cuts for intricate designs, this device has become an indispensable tool in many industries. In this article, we’ll dive into what makes this device special, its benefits, applications, and how it compares to traditional cutting tools. Let’s get started!

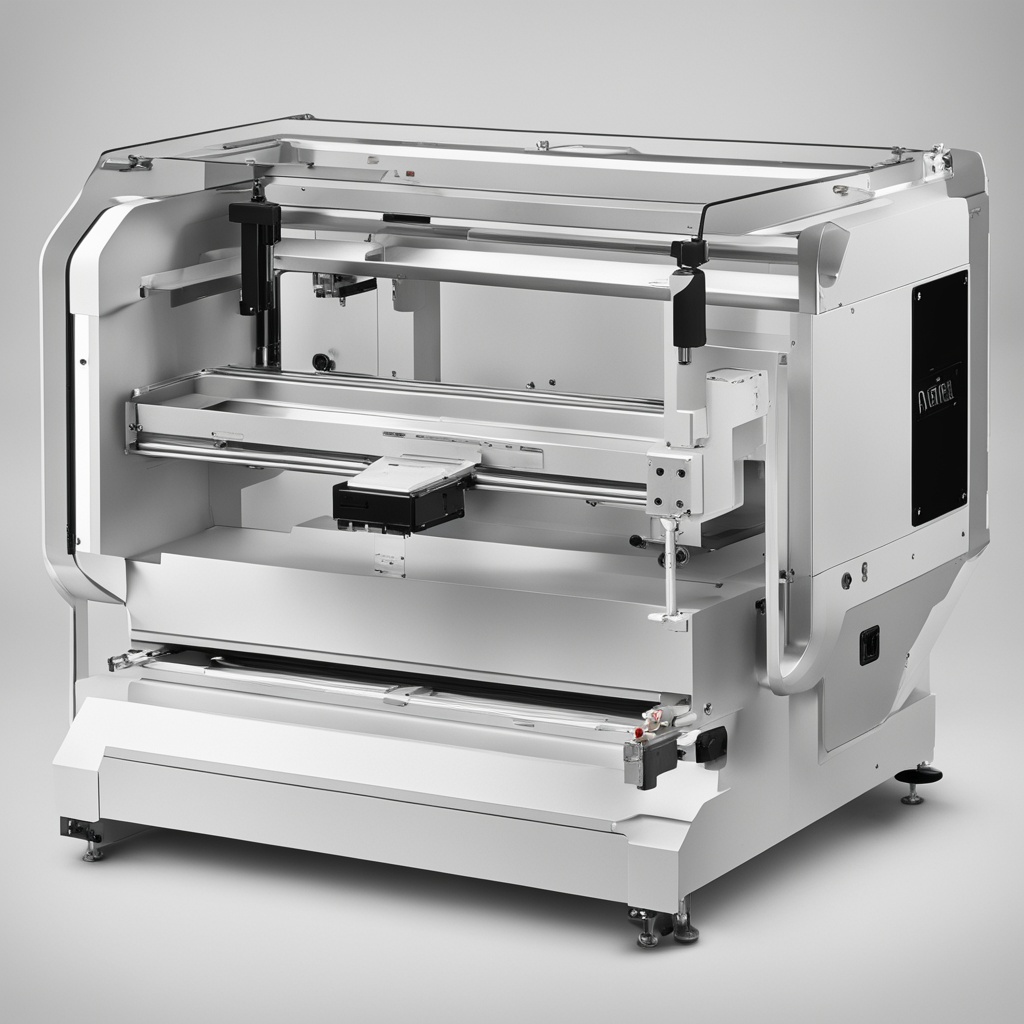

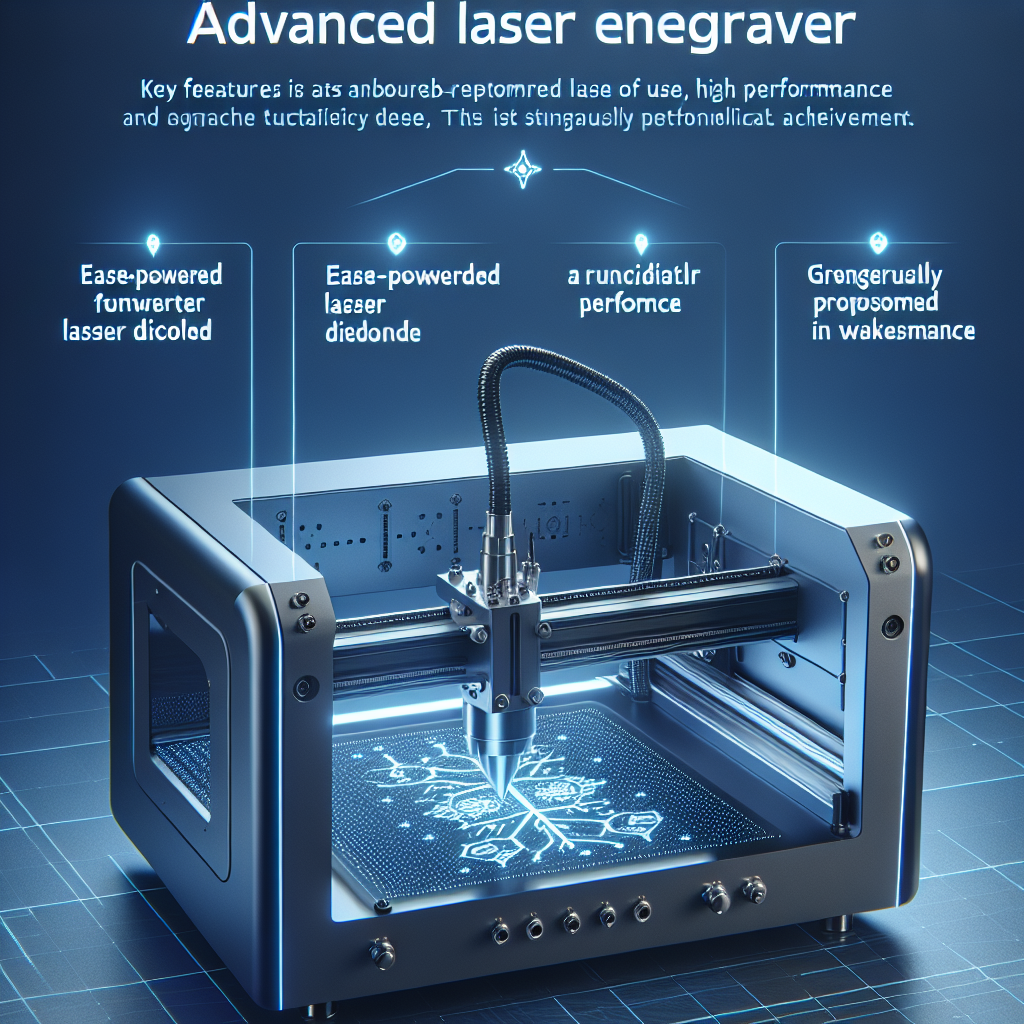

What Is a Plastic Laser Cutter Handheld?

A plastic laser cutter handheld is a compact, portable device designed for cutting and engraving materials like plastic, wood, fabric, and more. Unlike traditional cutting tools that rely on blades or mechanical movement, this device uses a focused beam of light (laser) to make precise cuts. The laser heats the material, vaporizing it to create clean, accurate cuts without leaving rough edges.

This tool is ideal for hobbyists, crafters, and professionals who need high precision in their projects. Its portability makes it a favorite among those who work on-the-go or in small workshop settings. With its user-friendly design, even beginners can master the basics quickly.

Why Choose a Plastic Laser Cutter Handheld?

There are several reasons why this device has gained popularity over traditional cutting tools:

- Precision and Accuracy: The laser beam is incredibly thin, allowing for intricate designs and cuts that would be nearly impossible with a blade.

- Portability: Being handheld, this device offers unmatched flexibility, making it easy to work on various surfaces and materials without being tied to a fixed location.

- Speed: Compared to manual cutting methods, the laser cutter delivers faster results while maintaining high-quality output.

- Versatility: It can handle a wide range of materials, including plastic, wood, leather, and even some metals (with the right settings).

These benefits make it an excellent choice for industries like crafting, model making, sign-making, and electronics prototyping.

Applications of a Plastic Laser Cutter Handheld

The applications of this device are vast and varied. Here are some common uses:

- Crafting and Art: Engraving personalized designs on jewelry, name tags, or decorative items.

- Model Making: Creating intricate parts for scale models with precision.

- Sign-Making: Cutting letters and logos out of plastic or wood for signage.

- Electronics Prototyping: Cutting through circuit boards or creating custom housings for components.

The plastic laser cutter handheld is limited only by your creativity! Whether you’re working on a small project at home or running a professional workshop, this tool can handle it all.

How Does a Plastic Laser Cutter Handheld Work?

Understanding the basic principles behind how this device works can help you use it more effectively. Here’s a simplified explanation:

- Laser Generation: The device generates a laser beam using a diode or other laser source.

- Focusing the Beam: The beam is focused through a lens to create an intense, pinpoint light source.

- Cutting/Engraving: As the beam hits the material, it heats and vaporizes the material, creating a clean cut or engraved surface.

Modern handheld models often come with adjustable settings to control the power and speed of the laser, allowing for greater customization depending on the material being cut.

LIMITATIONS AND SAFETY CONSIDERATIONS

While the plastic laser cutter handheld is a powerful tool, it does have some limitations:

- Material Thickness: It works best on thin materials. Cutting through thick plastic or wood may require a more robust machine.

- Laser Safety: Always wear protective eyewear when using this device, as the laser beam can cause eye damage if not handled properly.

Additionally, improper use can lead to uneven cuts or damage to the material. Always follow the manufacturer’s guidelines and practice in a well-ventilated area to avoid inhaling fumes produced during cutting.

COMPARISON WITH TRADITIONAL CUTTING TOOLS

Compared to traditional tools like scalpels or rotary cutters, the plastic laser cutter handheld offers several advantages:

- Clean Cuts: No jagged edges or rough surfaces.

- Faster Results: Completed projects in less time with higher precision.

- Reduced Waste: Minimal material waste due to precise cutting capabilities.

However, it’s important to note that this device may not be suitable for all materials or projects. For example, thick metal sheets would require a more powerful machine.

MAINTENANCE AND TIPS FOR LONGEVITY

To ensure your plastic laser cutter handheld remains in top condition:

- Clean Regularly: Dust and debris can interfere with the laser’s performance. Clean the lens and housing regularly.

- Store Properly: Keep it in a dry, cool place to prevent damage from humidity or temperature fluctuations.

- Follow Safety Guidelines: Always prioritize safety to avoid accidents and extend the tool’s lifespan.

Taking good care of your device will ensure it remains reliable for years to come.

FREQUENTLY ASKED QUESTIONS (FAQs)

1. Is a plastic laser cutter handheld safe to use?

As long as you follow safety precautions like wearing protective eyewear and working in a well-ventilated area, it is safe.

2. What materials can it cut?

It works best on thin plastics, wood, fabric, leather, and some metals. Avoid using it on thick or reflective materials without proper adjustments.

3. Can I use it for engraving?

Yes! It’s excellent for creating detailed engravings on various surfaces.

4. How easy is it to learn to use?

With a bit of practice, even beginners can master the basics. Most models come with user-friendly interfaces and guides.

CONCLUSION

The plastic laser cutter handheld is an innovative tool that has revolutionized how we approach cutting and engraving tasks. Its combination of precision, portability, and versatility makes it a must-have for anyone looking to take their projects to the next level. Whether you’re a hobbyist or a professional, this device offers unmatched capabilities that can elevate your work.

If you’re considering investing in one, make sure to research different models and read reviews to find the best fit for your needs. Happy cutting!