Exploring the Laser Cutter Cal Poly: Features, Benefits, and Applications

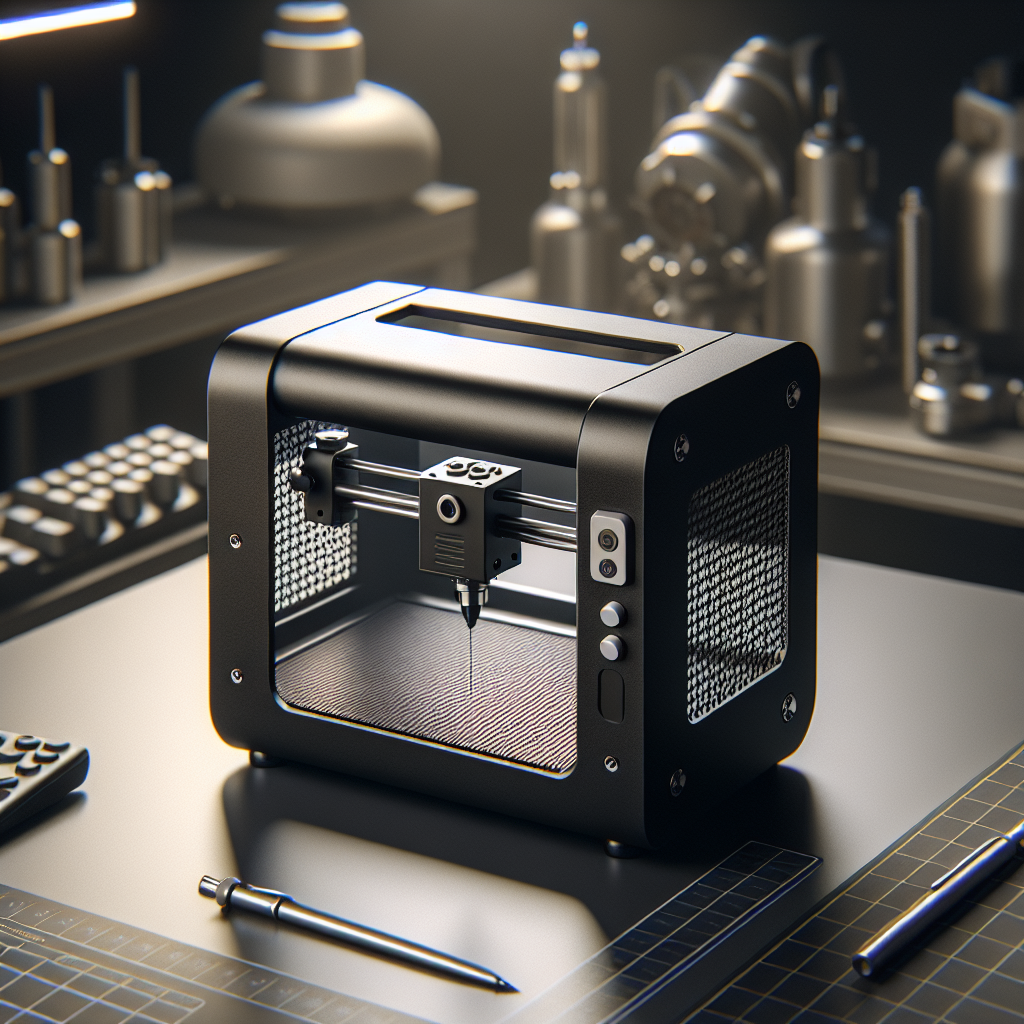

Laser cutting technology has revolutionized industries across the board, offering precision, efficiency, and versatility that traditional methods simply cannot match. Among the various laser cutting tools available, the laser cutter cal poly stands out as a powerful solution for a wide range of applications. Whether you’re working in metal fabrication, woodworking, or even creating custom designs for coffee cups, this machine is designed to deliver exceptional results. In this article, we’ll delve into the features, benefits, and applications of the laser cutter cal poly, while also addressing some common questions about its functionality.

What Is a Laser Cutter?

A laser cutter is a tool that uses a focused beam of light to cut or engrave materials with high precision. Unlike traditional cutting methods, which often require physical contact with the material, laser cutting relies on heat generated by the laser beam to melt, burn, or vaporize the material being cut. This non-contact method ensures minimal mechanical distortion and allows for intricate designs and patterns that would be challenging to achieve manually.

The laser cutter cal poly is specifically designed to handle both metal and wood, making it a versatile tool for various projects. Its ability to work with different materials makes it an excellent choice for hobbyists, craftsmen, and professionals alike. Whether you’re creating custom artwork, industrial parts, or even laser-engraved coffee cups, this machine offers the precision and versatility needed to bring your ideas to life.

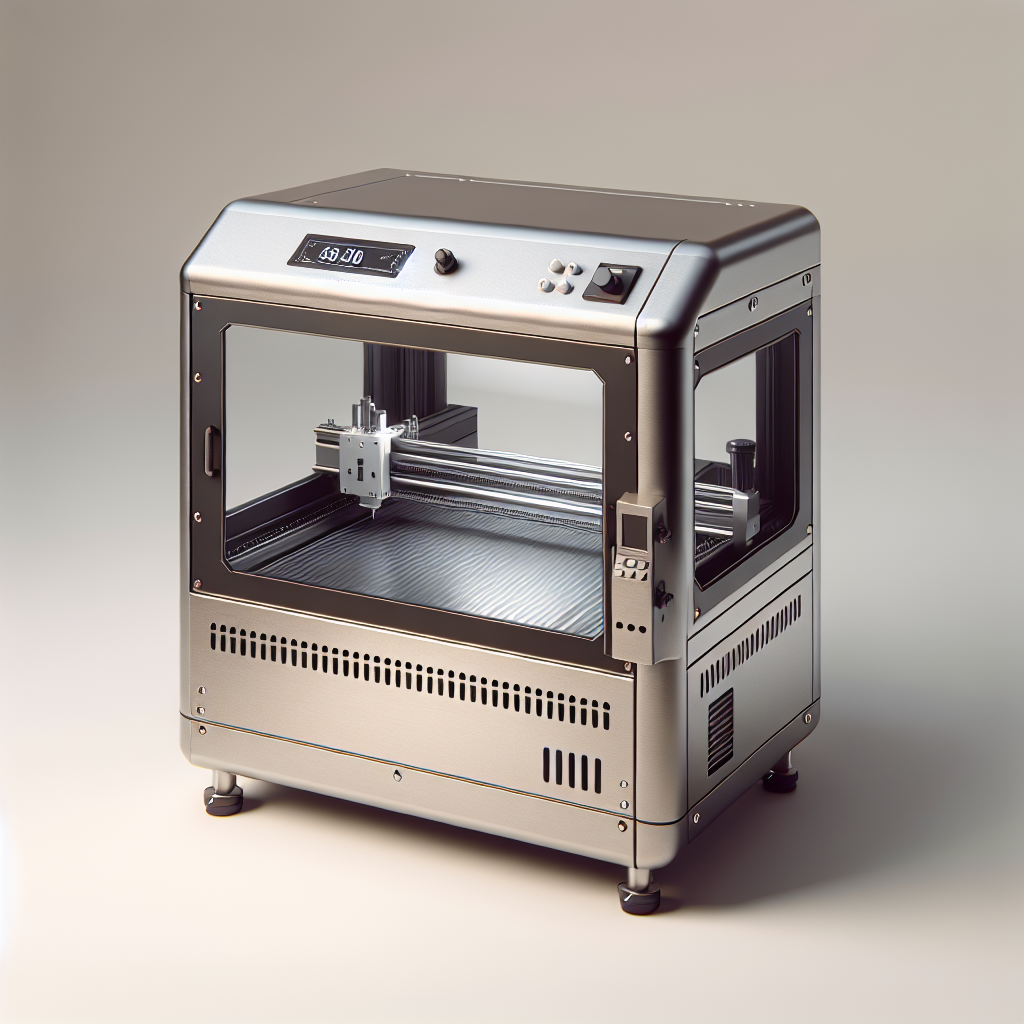

Key Features of the Laser Cutter Cal Poly

The laser cutter cal poly boasts a range of features that set it apart from other laser cutting tools on the market. Here are some of its standout characteristics:

- High Precision Cutting: The machine uses advanced optics to focus the laser beam with pinpoint accuracy, ensuring clean and precise cuts every time.

- Versatile Material Compatibility: It can work with both metal and wood, giving you the flexibility to tackle a wide variety of projects.

- User-Friendly Interface: The intuitive controls make it easy for even beginners to operate, reducing the learning curve and increasing productivity.

- Durable Construction: Built with high-quality materials, this laser cutter is designed to withstand heavy use while maintaining optimal performance over time.

- Eco-Friendly Operation: The machine produces minimal waste and operates efficiently, making it a sustainable choice for your projects.

These features combine to create a tool that is both powerful and accessible, enabling users to achieve professional-grade results without the need for extensive training or expensive setups.

Applications of the Laser Cutter Cal Poly

The laser cutter cal poly is incredibly versatile, with applications spanning numerous industries and hobbies. Here are some of the most common uses:

- Metal Fabrication: From cutting intricate shapes for industrial parts to creating custom metal art, this machine excels in metal fabrication.

- Woodworking: The ability to work with wood makes it ideal for crafting furniture, decorative items, and even laser-engraved coffee cups.

- Creative Design: Artists can use the machine to create detailed engravings and patterns on various materials, bringing their visions to life.

- Prototyping: The precision of the laser cutter cal poly makes it a valuable tool for prototyping new products in industries like automotive, aerospace, and electronics.

Whether you’re working on a small-scale project or a large production run, this machine offers the flexibility and reliability needed to meet your needs.

Advantages Over Traditional Cutting Methods

Compared to traditional cutting methods like sawing or machining, laser cutting offers several advantages. Here are some of the key benefits:

- Higher Precision: Laser cutting allows for intricate and complex designs that would be difficult or impossible to achieve with manual tools.

- Faster Processing: The machine can cut through materials quickly, reducing production time and increasing efficiency.

- Minimal Waste: Since the laser beam is highly focused, it minimizes material waste, making the process more cost-effective.

- No Physical Contact: Unlike traditional cutting methods, laser cutting doesn’t require physical contact with the material, reducing the risk of damage or deformation.

These advantages make the laser cutter cal poly a preferred choice for professionals who value precision, speed, and efficiency in their work.

Frequently Asked Questions About the Laser Cutter Cal Poly

If you’re new to laser cutting or considering purchasing the laser cutter cal poly, you might have some questions. Here are answers to some of the most common ones:

- Q: Can it cut through thick materials?

A: Yes, the machine is capable of cutting through a variety of thicknesses depending on the material and laser power.

- Q: Is it safe to use?

A: When used properly with safety precautions in place, such as wearing protective eyewear and ensuring adequate ventilation, the machine is safe for operation.

- Q: How easy is it to set up?

A: The setup process is relatively straightforward, and the user-friendly interface ensures that even beginners can get started quickly.

- Q: What kind of maintenance does it require?

A: Regular cleaning and inspection of the optics are necessary to ensure optimal performance. Detailed maintenance guidelines are typically provided by the manufacturer.

If you have more specific questions or concerns, referring to the user manual or contacting customer support can provide additional guidance.

Making the Most of Your Laser Cutter Cal Poly

To fully harness the potential of your laser cutter cal poly, it’s important to use it in conjunction with high-quality software and materials. Investing in reliable design software allows you to create intricate patterns and custom designs, while using compatible materials ensures consistent performance and results. Additionally, taking the time to learn advanced techniques and experimenting with different settings can help you unlock new creative possibilities.

If you’re looking for inspiration or tips on how to use your machine effectively, there are numerous online communities and forums where users share their experiences and projects. These resources can be invaluable for troubleshooting issues, learning new skills, and discovering innovative ways to use your laser cutter cal poly.

Conclusion

The laser cutter cal poly is an exceptional tool that offers precision, versatility, and reliability for a wide range of applications. Whether you’re working on metal fabrication, woodworking, or creative design projects, this machine provides the functionality needed to achieve professional-grade results. By understanding its features, benefits, and potential uses, you can make informed decisions about how to integrate it into your workflow and take your projects to the next level.

If you have any further questions or need assistance with your laser cutter cal poly, don’t hesitate to reach out to customer support or consult additional resources. With the right knowledge and tools, there’s no limit to what you can create!