The Ultimate Guide to Laser Cutters: Precision and Efficiency in Your Hands

Are you looking for a tool that combines precision, speed, and versatility? If so, then a laser cutter might just be the solution you’ve been searching for. Whether you’re a hobbyist, a small business owner, or a professional craftsman, a laser cutter can revolutionize the way you work. In this article, we’ll explore everything you need to know about laser cutters, from their benefits and applications to how they work and which one might be right for you.

What Is a Laser Cutter?

A laser cutter is a machine that uses a focused beam of light (laser) to cut, engrave, or etch materials with extreme precision. Unlike traditional cutting tools, laser cutters offer unparalleled accuracy and speed, making them ideal for a wide range of projects. Whether you’re working with wood, metal, plastic, glass, or fabric, a laser cutter can handle it all.

Laser cutters are used in various industries, including woodworking, metalworking, fashion, electronics, sign making, and even art. Their versatility makes them a valuable tool for both small-scale projects and large-scale production. But how exactly do they work?

How Does a Laser Cutter Work?

The laser cutter works by directing a high-powered laser beam at the material being cut. The laser heats the material to its melting or burning point, effectively vaporizing it and creating a clean, precise cut. This process is guided by computer software, which allows for intricate designs and patterns to be replicated with ease.

Here’s a step-by-step breakdown of how a laser cutter operates:

- The user creates a design or pattern using computer-aided design (CAD) software.

- The design is uploaded to the laser cutter via a control panel or connected computer.

- The laser beam is directed along the path of the design, cutting or engraving the material as it goes.

- The finished product is then removed from the machine for further use or assembly.

This process ensures that every cut is precise and consistent, eliminating the need for manual adjustments or corrections.

Benefits of Using a Laser Cutter

There are numerous advantages to using a laser cutter. Here are some of the most notable benefits:

- Precision and Accuracy: Laser cutters produce clean, precise cuts with minimal material waste. This is especially important for intricate designs or projects where exact measurements are critical.

- Speed: Compared to traditional cutting methods, laser cutters are much faster. They can complete complex patterns in a fraction of the time it would take manually.

- Versatility: Laser cutters can work with a wide variety of materials, making them suitable for almost any project. Whether you’re cutting thin metal sheets or thick wooden planks, a laser cutter can handle it.

- Low Maintenance: Unlike other cutting tools that require frequent blade replacements or sharpening, laser cutters have no moving parts and are relatively low-maintenance.

- Sustainability: Laser cutters minimize material waste and reduce the need for additional finishing steps, making them an eco-friendly option for many industries.

These benefits make laser cutters a popular choice among professionals and hobbyists alike. But what exactly can you do with one?

Applications of Laser Cutters

Laser cutters are incredibly versatile tools, and their applications are almost limitless. Here are some common uses:

- Cutting Metal: Laser cutters can easily slice through various types of metal, including steel, aluminum, and stainless steel. This makes them ideal for manufacturing parts or creating custom metal designs.

- Engraving Wood: For those in the woodworking industry, laser cutters can be used to engrave intricate patterns or text onto wood surfaces. This is perfect for creating personalized furniture, decorative items, or signage.

- Fabric Cutting: The fashion industry often uses laser cutters to create precise cuts in fabric. This ensures that patterns are accurate and consistent, reducing waste and saving time.

- Glass Etching: Laser cutters can be used to etch designs onto glass surfaces, creating beautiful decorative pieces or functional items like drink coasters or windows.

- Crafts and Art: Hobbyists and artists can use laser cutters to create custom designs for jewelry, sculptures, or home decor. The precision of the laser allows for intricate details that would be difficult to achieve manually.

These applications demonstrate just how versatile a laser cutter can be. Whether you’re working in a professional setting or simply looking to explore your creative side, there’s no limit to what you can achieve with one.

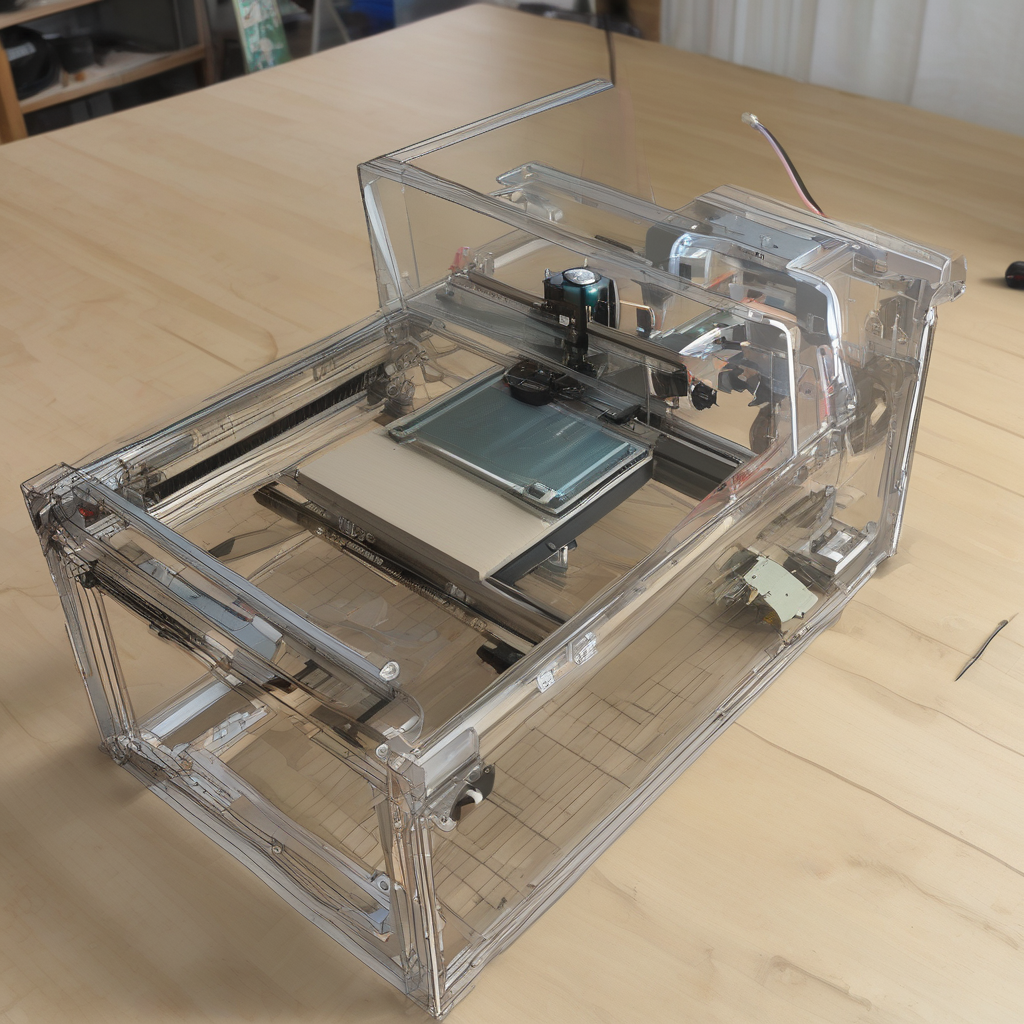

Choosing the Right Laser Cutter for Your Needs

With so many different types of laser cutters available on the market, it’s important to choose the right one for your specific needs. Here are some factors to consider when selecting a laser cutter:

- Type of Material: Consider what materials you’ll be working with most frequently. Different laser cutters are designed for different types of materials, so it’s important to choose one that can handle your primary material effectively.

- Budget: Laser cutters vary widely in price, depending on their size, power, and capabilities. Determine how much you’re willing to spend before making a purchase.

- Size and Portability: If space is a concern, look for a compact or portable laser cutter that can be easily moved as needed. On the other hand, if you plan to use it for large-scale projects, a larger machine might be more appropriate.

- Software Compatibility: Make sure the laser cutter you choose is compatible with the software you’ll be using. Many modern laser cutters come with user-friendly interfaces or are compatible with popular CAD programs.

- Maintenance and Support: Check the availability of replacement parts, technical support, and maintenance services for the laser cutter you’re considering. A reliable manufacturer can make a big difference in the long run.

Taking these factors into account will help you choose the best laser cutter for your needs and ensure that it meets all your project requirements.

The Future of Laser Cutting Technology

As technology continues to advance, so does the field of laser cutting. New innovations are being developed every year, making laser cutters even more powerful, efficient, and user-friendly. Some trends to watch for in the future include:

- Higher Precision: Advances in laser technology are allowing for even greater precision in cuts, enabling more intricate designs and tighter tolerances.

- AI Integration: Artificial intelligence is being integrated into laser cutting software, helping users optimize their designs and improve efficiency.

- Portability: Compact, portable laser cutters are becoming increasingly popular, allowing users to work on the go or in smaller spaces.

- Sustainability: As eco-consciousness grows, more emphasis is being placed on creating laser cutters that consume less energy and produce less waste.

These advancements are exciting for anyone who works with laser cutters, as they promise to open up even more possibilities in the future. Whether you’re a seasoned professional or just starting out, staying updated on these developments can help you stay ahead of the curve.

Maintenance and Safety Tips for Laser Cutters

While laser cutters are relatively low-maintenance compared to other cutting tools, proper care is still essential to ensure their longevity and optimal performance. Here are some tips for maintaining your laser cutter:

- Clean Regularly: Dust and debris can accumulate inside the machine over time, so it’s important to clean it regularly according to the manufacturer’s instructions.

- Inspect Components: Periodically check for any wear or damage to the laser head, mirrors, or other internal components. Replace them as needed to prevent issues down the line.

- Calibrate Regularly: Laser cutters require precise calibration to ensure accurate cuts. Follow the recommended calibration schedule provided by the manufacturer.

- Use Proper Safety Gear: Always wear appropriate safety gear when operating a laser cutter, including protective eyewear and gloves. Keep your work area well-ventilated to avoid inhaling any fumes from the cutting process.

- Follow Manufacturer Guidelines: Adhere strictly to the manufacturer’s instructions for use, maintenance, and troubleshooting to ensure safe and efficient operation of your laser cutter.

By following these tips, you can extend the life of your laser cutter and maintain its performance for years to come. Remember, safety should always be a top priority when working with powerful tools like laser cutters.

Frequently Asked Questions About Laser Cutters

If you’re new to laser cutting, you might have some questions about how it works and what to expect. Here are answers to some frequently asked questions:

- How does a laser cutter work? A laser cutter uses a focused beam of light (laser) to melt, burn, or vaporize materials, creating precise cuts or engravings.

- Is it safe to use a laser cutter? Yes, but only when used properly. Always wear protective gear and follow safety guidelines to minimize risks.

- Can I cut all types of materials with a laser cutter? No, not all materials are suitable for laser cutting. Common materials include wood, metal, plastic, and fabric, but some may require special settings or precautions.

- How much does a laser cutter cost? Prices vary widely depending on the size, power, and features of the machine. Entry-level models can start around $500, while industrial-grade cutters can cost tens of thousands of dollars.

- Do I need special training to use a laser cutter? While no formal training is required, it’s important to familiarize yourself with the machine’s operation and safety protocols before using it. Many manufacturers offer instructional guides or videos to help you get started.

These answers should give you a better understanding of what laser cutters are capable of and how to use them safely and effectively.

In Conclusion

Laser cutters are powerful, versatile tools that have revolutionized the way we approach cutting and engraving tasks. From their ability to work with a wide range of materials to their precision and efficiency, laser cutters offer countless possibilities for both professionals and hobbyists.

If you’re considering investing in a laser cutter, it’s important to do your research and choose one that aligns with your specific needs and budget. With proper care and maintenance, your laser cutter can serve you well for many years to come, helping you bring your creative visions to life.

So why not give laser cutting a try? Whether you’re creating custom designs, manufacturing parts, or simply exploring your artistic side, the possibilities are endless with a laser cutter. Happy cutting!