The Meterk Laser Engraver: A Comprehensive Guide

Welcome to an in-depth exploration of the , a cutting-edge tool designed for precision, creativity, and efficiency. Whether you’re a hobbyist, an artist, or a professional in the woodworking or crafting industry, this article will provide you with everything you need to know about this innovative machine.

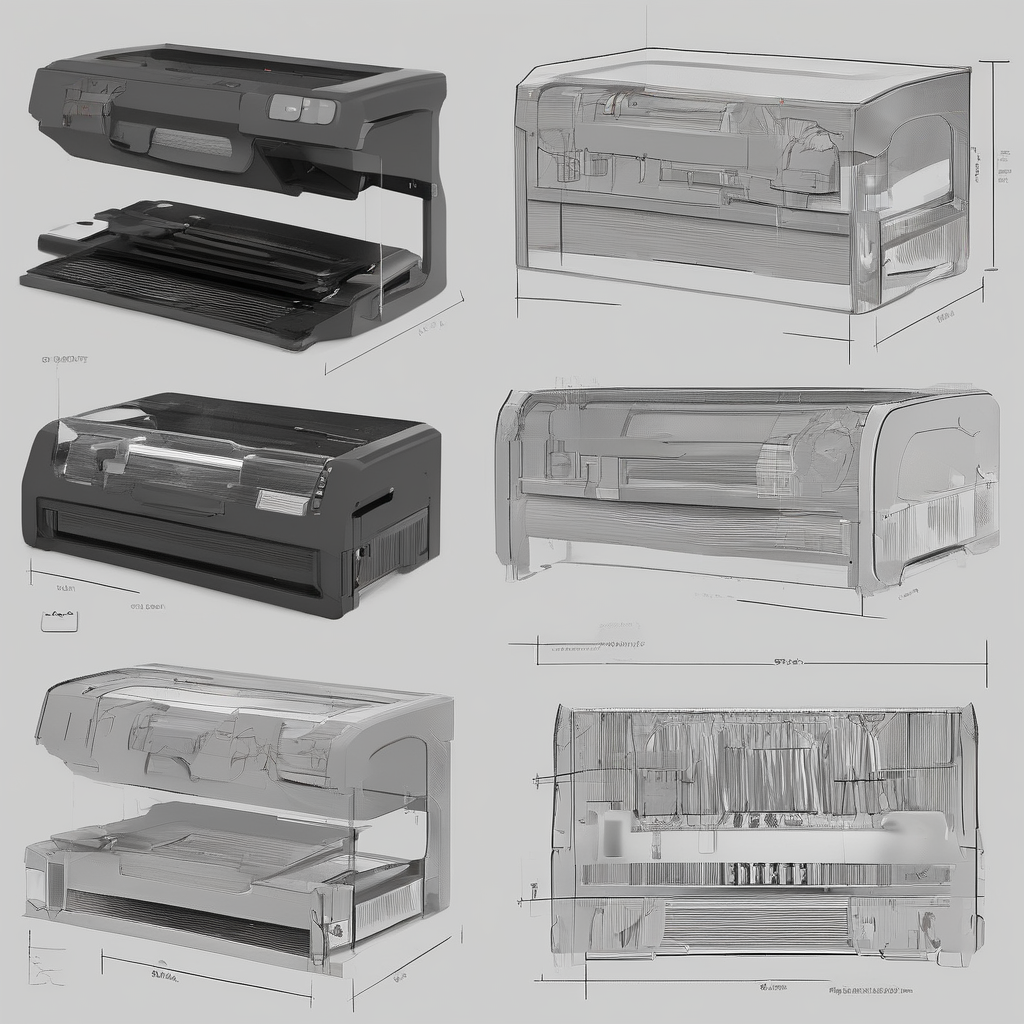

What is the Meterk Laser Engraver?

The is a state-of-the-art device that uses advanced laser technology to etch intricate designs, patterns, and text onto various materials. Primarily designed for wood, this machine can also work with other surfaces like leather, plastic, and metal, making it versatile for a wide range of applications. Its precision and ease of use make it an excellent choice for both beginners and seasoned craftsmen.

Key Features of the Meterk Laser Engraver

Before diving into the benefits and uses of this machine, let’s explore its standout features:

- Laser Technology: The machine employs a high-powered laser that ensures sharp and precise engravings. This technology allows for intricate details that are difficult to achieve with traditional engraving methods.

- User-Friendly Interface: Designed with simplicity in mind, the comes with an intuitive interface that makes it easy for users of all skill levels to operate.

- Compatibility: The machine supports a variety of materials, including wood, leather, plastic, and metal, making it suitable for diverse projects.

- High Precision: With adjustable settings, the laser can produce engravings with varying depths and widths, ensuring versatility in design outcomes.

- Safety Features: Equipped with safety guards and emergency stop mechanisms, this machine prioritizes user safety while maintaining high performance.

Benefits of Using the Meterk Laser Engraver

There are numerous advantages to using the , making it a valuable addition to any workshop or studio:

- Versatility: The ability to work with multiple materials ensures that this machine can handle a wide range of projects, from personalized gifts to industrial markings.

- Cost-Effective: Compared to traditional engraving methods, laser engraving is often more economical, especially for large-scale or complex designs.

- Ease of Use: The user-friendly interface and straightforward operation reduce the learning curve, allowing users to start projects quickly.

- Customization: The machine’s precision allows for highly detailed and customized engravings, making it ideal for creating unique pieces.

- Eco-Friendly: Unlike some other engraving methods that produce waste materials, laser engraving is a clean process with minimal environmental impact.

Applications of the Meterk Laser Engraver

The is a multi-functional tool with applications across various industries and hobbies. Here are some of its most common uses:

- Woodworking: Engrave intricate designs, logos, or personal messages onto wooden surfaces for furniture, decorative items, or custom gifts.

- Jewelry Making: Create detailed engravings on metal surfaces to add unique touches to jewelry pieces.

- Leather Crafting: Etch patterns or text onto leather goods like belts, wallets, and bags for a personalized finish.

- Signage and Marking: Use the machine to create professional-grade signage, tags, and labels with precise lettering and designs.

- Artistic Expression: Artists can use this tool to bring their creative visions to life by etching complex patterns and images onto various materials.

How to Use the Meterk Laser Engraver?

Operating the is a straightforward process, but it’s essential to follow the guidelines for optimal results and safety:

- Preparation: Ensure the surface you’re engraving is clean and free of dirt or grease. For wood, sanding the surface beforehand can improve the engraving quality.

- Design Setup: Use compatible software to design your engraving pattern or text. Most machines come with pre-installed software, but you can also use third-party programs for more customization.

- Material Placement: Secure the material firmly on the machine’s worktable to prevent movement during engraving. Proper clamping ensures accurate results.

- Laser Settings: Adjust the laser power, speed, and focal length based on the material and desired depth of the engraving.

- Engraving Process: Once everything is set up, initiate the engraving process. The machine will follow the programmed design, creating precise engravings with minimal human intervention.

- Cooling and Post-Processing: After engraving, allow the material to cool down before handling. Sand or finish the engraved area as needed for a polished look.

Maintenance and Care Tips

To ensure the longevity and performance of your , follow these maintenance tips:

- Clean Regularly: Dust and debris can accumulate inside the machine, so clean it regularly using a soft cloth or compressed air.

- Lubricate Moving Parts: Apply a small amount of lubricant to moving components to keep them functioning smoothly.

- Check Laser Alignment: Periodically verify the laser alignment to maintain precision in engravings. Misalignment can lead to blurry or uneven results.

- Update Software: Keep the machine’s software up to date to access new features and improvements.

- Handle with Care: Avoid dropping or exposing the machine to extreme temperatures, as this can damage its internal components.

Frequently Asked Questions (FAQs)

If you’re considering purchasing a , here are answers to some common questions:

- Is it easy to learn how to use this machine? Yes, the user-friendly interface and intuitive controls make it accessible for users of all skill levels. Additionally, many machines come with comprehensive manuals or online tutorials.

- Can it engrave on all types of materials? While primarily designed for wood, the can also work with other materials like leather, plastic, and metal. However, results may vary depending on the material’s thickness and density.

- How much maintenance does it require? Regular cleaning and occasional lubrication are sufficient to keep the machine in optimal condition. Frequent use may necessitate more frequent maintenance.

- Is it safe to operate? Yes, but always wear protective eyewear when operating the machine and ensure proper ventilation in your workspace to avoid inhaling fumes from engraved materials.

Conclusion

The is a versatile and powerful tool that can elevate your woodworking, crafting, or artistic projects to new heights. With its ease of use, precision capabilities, and versatility across various materials, it’s an excellent investment for both hobbyists and professionals alike. By following the provided guidelines and maintaining proper care, you can enjoy years of reliable service from this innovative machine.