The Art and Science of Laser Engraving Steel: Precision Meets Creativity

Laser engraving steel has become one of the most popular methods for creating intricate designs, markings, and patterns on metal surfaces. This innovative technique combines precision, durability, and artistic expression, making it a favorite among craftsmen, artists, and industries alike. Whether you’re working on custom jewelry, industrial components, or decorative items, laser engraving steel offers unparalleled flexibility and quality. But what exactly is laser engraving? How does it work? And why has it become so widely adopted in recent years? Let’s dive into the world of laser engraving steel and explore its fascinating possibilities.

What Is Laser Engraving Steel?

Laser engraving steel is a process that uses high-powered laser beams to intricate designs or text onto steel surfaces. Unlike traditional methods such as acid etching or mechanical cutting, laser engraving provides unparalleled precision and control. The laser beam heats the metal surface, vaporizing or melting it to create permanent markings. This method is not only faster but also produces cleaner and more detailed results compared to conventional techniques.

One of the key advantages of laser engraving steel is its ability to work on a wide variety of materials, including stainless steel, mild steel, and other alloys. The process can be used for both small-scale projects, such as creating personalized jewelry, and large-scale applications, like marking industrial machinery. Its versatility makes it an indispensable tool in modern manufacturing and craftsmanship.

Benefits of Laser Engraving Steel

The benefits of laser engraving steel are numerous and have contributed to its growing popularity across various industries. Let’s take a look at some of the key advantages:

- Precision and Detail: Laser engraving allows for extremely fine details, making it ideal for creating complex patterns or text that would be difficult to achieve with other methods.

- Durability: The markings created by laser engraving are permanent and resistant to wear and tear, ensuring long-lasting results.

- Versatility: Laser engraving can be used on a wide range of materials and for various applications, from decorative art to industrial components.

- Eco-Friendly: Compared to traditional methods that use chemicals or mechanical abrasion, laser engraving is environmentally friendly as it produces minimal waste and does not require harmful substances.

These benefits make laser engraving steel a preferred choice for professionals seeking high-quality, efficient, and sustainable solutions for their projects.

Applications of Laser Engraving Steel

Laser engraving steel has found its way into numerous industries and creative fields. Here are some of the most common applications:

- Jewelry Making: Custom engravings on rings, bracelets, and other jewelry pieces allow for personalized touches that make each piece unique.

- Signage and plaques: Businesses often use laser engraving to create professional-grade signs, nameplates, and commemorative plaques with sharp, readable text.

- Industrial Marking: Laser engraving is used to mark serial numbers, barcodes, and other identifiers on machinery and equipment, ensuring traceability and compliance with industry standards.

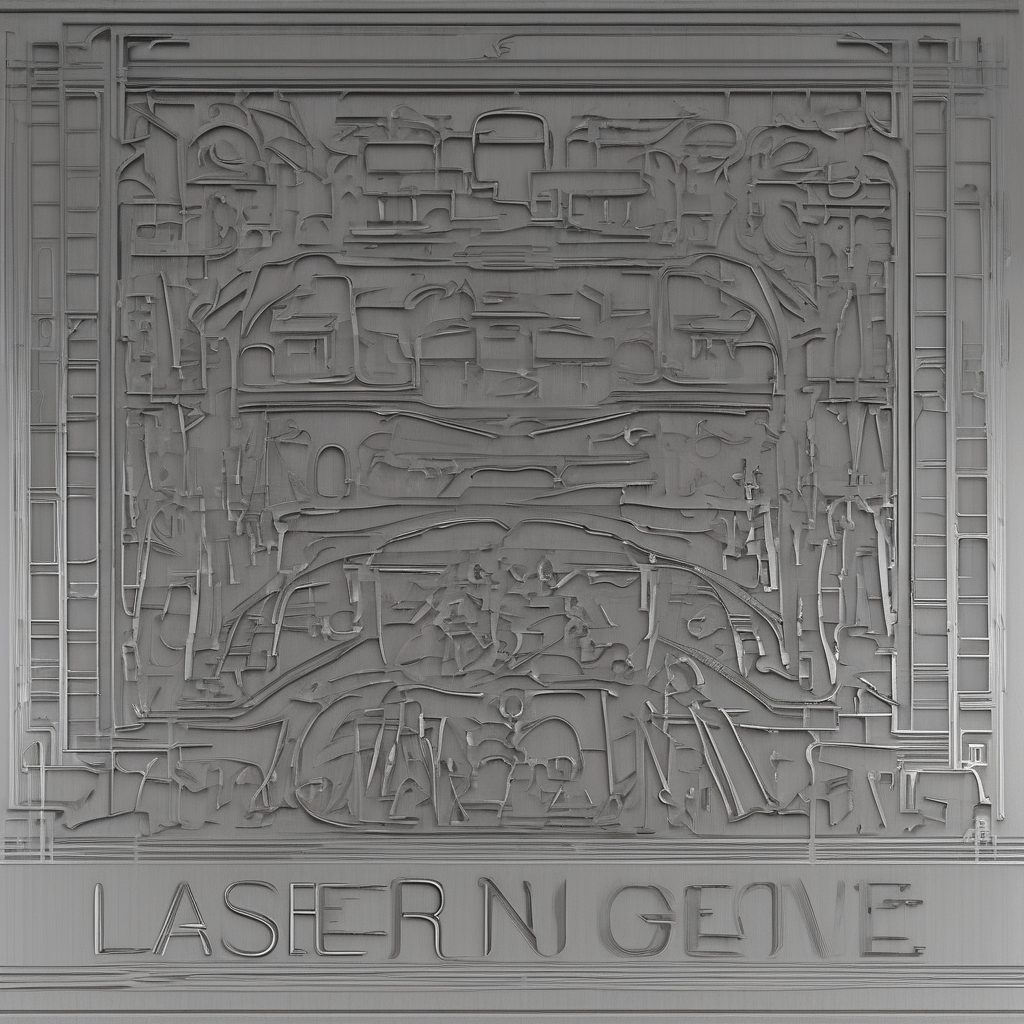

- Art and Decoration: Artists use laser engraving to create intricate designs on steel surfaces, turning ordinary materials into extraordinary works of art.

The versatility of laser engraving steel makes it a go-to solution for both practical and aesthetic purposes. Whether you’re looking to customize a small item or produce large-scale signage, this technique delivers exceptional results every time.

How Does Laser Engraving Steel Work?

To understand the process better, let’s break down how laser engraving steel works:

- Laser Beam Generation: A high-powered laser beam is generated by a laser machine. The wavelength and intensity of the beam can be adjusted to suit different materials and design requirements.

- Material Vaporization or Melting: The laser beam targets specific points on the steel surface, heating it rapidly to the point of vaporization or melting. This creates a permanent mark without damaging the surrounding area.

- Digital Control: Modern laser engraving machines are controlled by computer software, allowing for precise and repeatable designs. This ensures consistency in large-scale production runs or custom projects.

- Post-Processing: After the engraving is complete, the steel surface may be treated to enhance the visibility of the markings or protect them from environmental factors.

This process not only ensures high precision but also allows for real-time adjustments, making it ideal for both small and large-scale projects.

Choosing the Right Equipment for Laser Engraving Steel

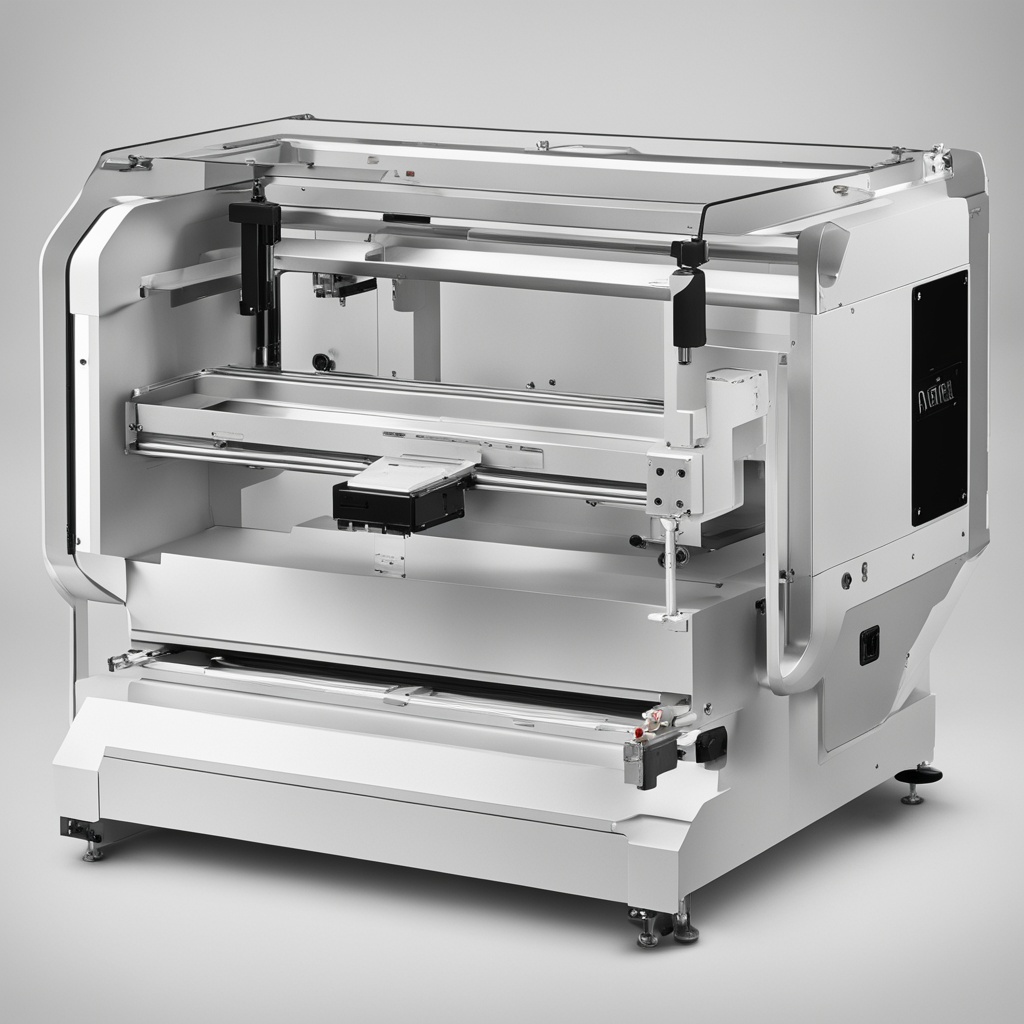

To achieve optimal results in laser engraving steel, selecting the right equipment is crucial. Here are some factors to consider:

- Laser Machine Type: Different types of lasers, such as CO2 or fiber lasers, are suited for various materials and applications. For steel, a fiber laser is often recommended due to its high efficiency and precision.

- Software Compatibility: Ensure that your laser machine is compatible with the design software you plan to use. Popular options include Adobe Illustrator and CorelDRAW.

- Material Preparation: Properly preparing the steel surface, such as cleaning it of any dirt or grease, ensures better engraving results.

Investing in high-quality equipment and understanding its capabilities will help you unlock the full potential of laser engraving steel. For those looking to get started, there are many affordable options available, including desktop laser machines like the [insert product name], which offer excellent performance for small-scale projects.

Frequently Asked Questions About Laser Engraving Steel

If you’re new to laser engraving steel, you might have some questions. Here are answers to some of the most common ones:

- Is laser engraving difficult to learn? With practice and the right equipment, laser engraving can be mastered even by beginners. Many machines come with user-friendly interfaces and tutorials to help you get started.

- Can I engrave on all types of steel? Yes, laser engraving works on a wide variety of steel grades, including stainless steel, mild steel, and tool steel. However, the settings may need to be adjusted for different materials.

- How long does it take to complete an engraving project? The time required depends on the complexity of the design and the size of the project. Simple text or small patterns can be completed in minutes, while intricate designs may take longer.

By addressing these questions, you’ll be better equipped to start your journey into the world of laser engraving steel.

The Future of Laser Engraving Steel

As technology continues to evolve, so does the field of laser engraving. Innovations such as higher-powered lasers and advanced software are opening up new possibilities for creativity and efficiency. The future of laser engraving steel looks promising, with potential advancements in automation, AI-driven design tools, and even more eco-friendly processes.

If you’re looking to explore the world of laser engraving steel, now is a great time to get started. With the right equipment, knowledge, and creativity, you can create stunning designs that combine functionality with artistic expression. Whether you’re an artist, a hobbyist, or a professional, laser engraving offers endless opportunities for innovation and inspiration.

So why wait? Take the plunge into laser engraving steel and start crafting your masterpiece today!