Understanding Laser Engraver Y-Axis Movement: A Comprehensive Guide

Welcome to this detailed guide on understanding how a operates, with a particular focus on the Y-axis movement. Whether you’re a newcomer to laser engraving or an experienced user looking to deepen your knowledge, this article will provide valuable insights into how the Y-axis functions and why it’s crucial for achieving precise and high-quality engravings.

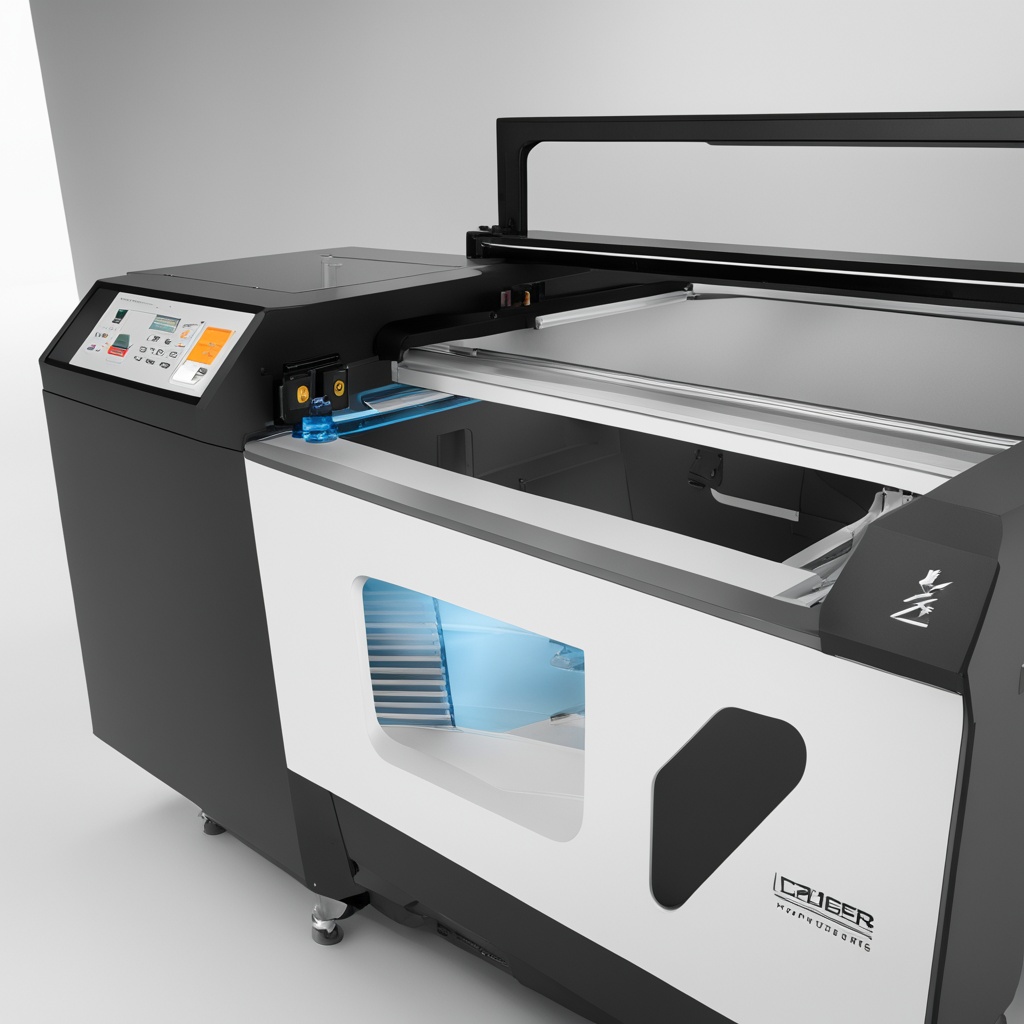

What is a Laser Engraver?

A is a machine that uses laser technology to etch or cut designs onto various materials such as wood, metal, plastic, and glass. Unlike traditional engraving methods, laser engraving offers unparalleled precision, speed, and versatility. The machine operates on a CNC (Computer Numerical Control) system, which means it can follow pre-programmed instructions to create intricate designs with minimal human intervention.

The key components of a laser engraver include:

- A laser source (usually CO2 or fiber laser)

- X-axis and Y-axis motors for movement

- Z-axis control for adjusting the laser’s height

- A CNC controller to manage the machine’s operations

- Software for designing and programming engravings

The X and Y axes are responsible for moving the laser head across the material, while the Z-axis controls the distance between the laser and the workpiece. Together, these components ensure that the laser can create precise and detailed patterns on a wide range of materials.

Understanding Y-Axis Movement

The Y-axis is one of the two horizontal axes (the other being the X-axis) in a CNC machine. It plays a critical role in determining how the laser engraver moves across the material surface. The Y-axis movement is essential for creating designs that extend vertically or horizontally, depending on the orientation of the workpiece.

In most laser engravers, the Y-axis motor is responsible for moving the laser head up and down (or left to right, depending on the machine’s configuration). This movement allows the laser to trace out patterns along the vertical axis. For example, if you’re engraving a nameplate with text that spans multiple lines, the Y-axis ensures that each line is positioned correctly relative to the others.

One of the most common questions about laser engravers is: How does the Y-axis movement affect the quality of engravings? The answer lies in the precision and consistency of the motor. A well-calibrated Y-axis motor ensures that the laser follows the programmed path accurately, resulting in sharp and clean engravings. On the other hand, a misaligned or faulty Y-axis can lead to distorted designs or uneven cuts.

The Importance of Y-Axis Calibration

Calibration is a critical step in maintaining the performance of your . The Y-axis, like all other axes, must be properly calibrated to ensure accurate movement and positioning. Without calibration, the machine may not align with the workpiece correctly, leading to off-center engravings or misaligned patterns.

Here are some steps you can take to calibrate your Y-axis:

- Check the alignment of the motor and ensure it is securely fastened

- Adjust the belt tension if necessary (for machines with belt-driven Y-axes)

- Use calibration tools or software to fine-tune the axis position

- Test the machine with a simple engraving pattern to verify accuracy

If you notice any discrepancies in your engravings, it’s essential to address them promptly. Regular maintenance and calibration can help prevent issues before they become serious, ensuring that your laser engraver continues to produce high-quality results.

Tips for Achieving Perfect Engraving Results

To maximize the performance of your , here are some tips to keep in mind:

- Always use high-quality materials that are compatible with your laser settings

- Experiment with different power levels and speeds to find the optimal settings for your project

- Keep the work area clean to prevent dust or debris from interfering with the machine’s operation

- Update your CNC software regularly to ensure you have access to the latest features and improvements

- Store your laser engraver in a dry, dust-free environment when not in use

By following these tips, you can help extend the life of your laser engraver while achieving consistently excellent results.

Frequently Asked Questions

Here are some common questions about and their Y-axis movement:

- What happens if the Y-axis is not properly aligned?

If the Y-axis is misaligned, your engravings may appear distorted or offset. This can lead to wasted materials and time, so it’s crucial to ensure proper alignment before starting any project. - Can I adjust the Y-axis movement speed?

Yes, most laser engravers allow you to adjust the speed of both the X and Y axes. Slower speeds are generally better for intricate designs, while faster speeds can be used for simpler patterns or larger areas. - How often should I calibrate my Y-axis?

It’s a good idea to calibration your Y-axis at least once every few months or whenever you notice inconsistencies in your engravings. Regular maintenance helps ensure long-term performance and accuracy.

Conclusion

The Y-axis is an essential component of any laser engraver, playing a vital role in creating precise and detailed designs. By understanding how the Y-axis works and maintaining it properly, you can achieve consistently high-quality results with your machine. Whether you’re a hobbyist or a professional, taking the time to learn about your equipment will help you get the most out of your laser engraving projects.

If you have any further questions or need assistance with your , don’t hesitate to consult the user manual or reach out to the manufacturer for support. Happy engraving!

laser engraver engraver y axis moves to which directionlaser engraver engraver y axis moves to which direction