The Ultimate Guide to Laser Engrave Blanks

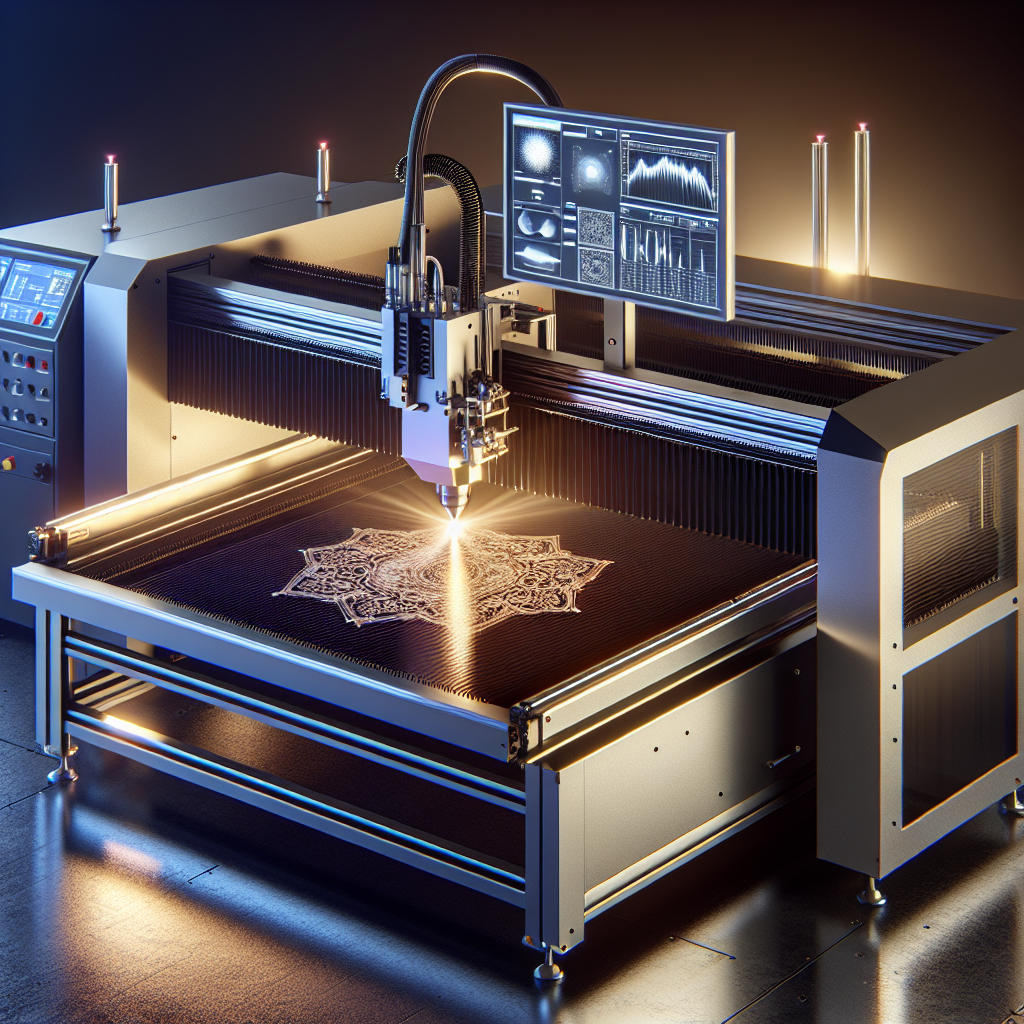

Laser engraving has revolutionized the way we create personalized and durable markings on various materials. Among the most versatile tools in this field is the laser engrave blanks machine, which combines precision, efficiency, and ease of use. In this comprehensive guide, we will explore everything you need to know about laser engrave blanks, including their applications, benefits, and how they compare to traditional methods. Whether you’re a professional or just starting out, this article will provide valuable insights into the world of laser engraving.

What Are Laser Engrave Blanks?

Laser engrave blanks are specially designed materials that serve as the base for creating custom engravings using a laser engraver machine. These blanks come in various shapes, sizes, and materials, such as wood, plastic, metal, or acrylic, making them suitable for a wide range of applications. The laser engrave blanks machine uses a focused laser beam to etch designs, text, or patterns onto the surface of these blanks, resulting in permanent and high-quality engravings.

One common question is: What makes laser engrave blanks different from other materials? The answer lies in their composition and finish. Laser engrave blanks are often pre-treated to ensure smooth engraving and consistent results. For example, some blanks are coated with a protective layer that enhances the clarity of the engraved text or design.

Applications of Laser Engrave Blanks

The versatility of laser engrave blanks makes them ideal for numerous industries and creative projects. Here are some of the most common applications:

- Jewelry making: Engraving names, dates, or symbols on rings, pendants, and other accessories.

- Furniture and home decor: Adding decorative patterns or personalized messages to wooden furniture, picture frames, or household items.

- Business products: Customizing promotional items like keychains, USB drives, and name tags with company logos or slogans.

- Crafts and art: Creating intricate designs on acrylic sheets, metal plates, or wooden panels for artistic purposes.

Laser engrave blanks are also widely used in the medical and industrial sectors for marking components with serial numbers, barcodes, or safety information. How does this technology benefit these industries? The precision and permanence of laser engravings ensure that markings remain intact even under harsh conditions, reducing the risk of errors or misidentification.

Benefits of Using Laser Engrave Blanks

There are several advantages to using laser engrave blanks over traditional engraving methods. Let’s break them down:

- Precision: The laser beam ensures accurate and detailed engravings, even on complex designs.

- Speed: Laser engravers are much faster than manual engraving tools, saving time and increasing productivity.

- Versatility: Compatible with a wide range of materials, making it suitable for diverse projects.

- Durability: Engravings are permanent and resistant to wear and tear.

Another benefit is the ability to create customized designs. With laser engrave blanks, you can upload your own artwork or text files and have them engraved with ease. Is this process user-friendly? Absolutely! Most modern laser engravers come with intuitive software that simplifies the design-to-engraving workflow.

How Do Laser Engrave Blanks Compare to Traditional Methods?

Compared to traditional engraving methods, such as hand carving or mechanical cutting, laser engrave blanks offer several advantages. Let’s explore some key differences:

- Precision: Lasers can achieve finer details and more complex patterns than manual or mechanical tools.

- Speed: Laser engraving is significantly faster, reducing the time required for large-scale projects.

- Cleanliness: Laser engravers produce minimal waste and mess compared to traditional methods.

What about cost? While laser engrave blanks may have a higher upfront cost than some traditional materials, the long-term savings from reduced labor and material waste make them a cost-effective choice. Additionally, the ability to reuse the machine for multiple projects further enhances its value.

Choosing the Right Laser Engrave Blanks

Selecting the right laser engrave blanks depends on your specific project requirements. Here are some factors to consider:

- Material: Choose a material that aligns with your design and durability needs. For example, metal is ideal for industrial applications, while acrylic is perfect for creating lightweight and colorful engravings.

- Size and shape: Ensure the blanks are appropriately sized for your project to avoid unnecessary waste or resizing costs.

- Finish: Some blanks come with a pre-treated finish that enhances engraving quality. Consider this if you want a polished or matte finish without additional post-processing.

Where can I find high-quality laser engrave blanks? Many online retailers and specialty stores offer a wide range of options, often with custom orders available. It’s also worth checking reviews and ratings to ensure you’re getting reliable products.

Maintenance and Care for Laser Engrave Blanks

To maximize the lifespan and performance of your laser engrave blanks, proper maintenance is essential. Here are some tips:

- Clean regularly: Remove dust, debris, or residual material from the machine after each use to prevent buildup and ensure optimal performance.

- Check for wear: Inspect the laser head and other components for signs of wear and replace them as needed.

- Follow safety guidelines: Always wear protective gear, such as goggles and gloves, when operating the machine to prevent accidents.

How often should I perform maintenance? It’s recommended to clean and inspect your machine after every few projects or as per the manufacturer’s instructions. Regular maintenance not only extends the life of your equipment but also ensures consistent engraving quality.

Conclusion

Laser engrave blanks have revolutionized the way we create custom designs and markings, offering unparalleled precision, speed, and versatility. Whether you’re a hobbyist, artist, or professional, understanding how to use these blanks effectively can elevate your projects to new heights. By considering factors such as material, size, and finish, you can choose the right blanks for your needs and achieve stunning results every time.

If you’re ready to dive into the world of laser engraving, consider investing in a high-quality laser engrave blanks machine. With proper care and technique, you’ll be creating beautiful, durable engravings in no time!