The Fiber Optic Laser Cutter: A Revolution in Engraving Tumblers and Acrylic Cutting

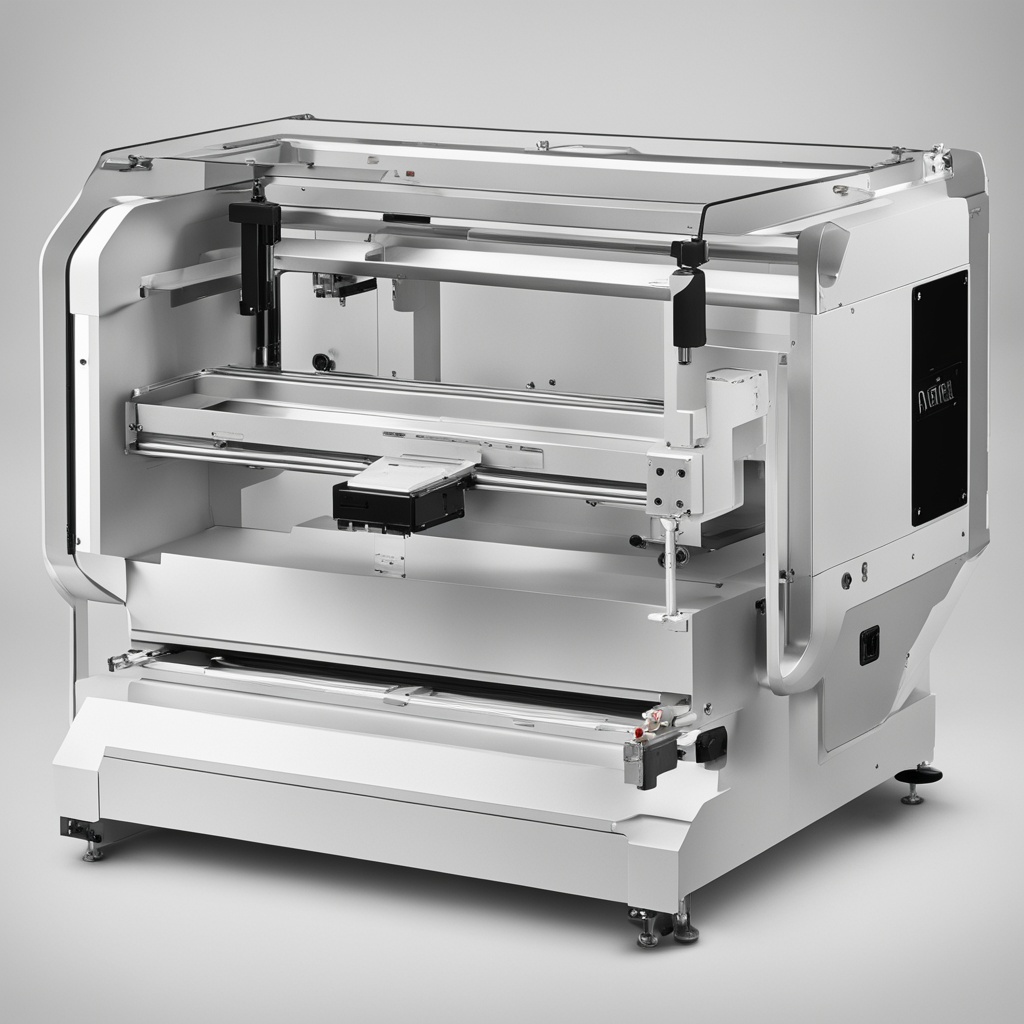

Laser technology has come a long way, revolutionizing industries from manufacturing to artistry. Among the latest innovations is the fiber optic laser cutter, which combines precision, speed, and versatility to create intricate designs on various materials. This article explores the features, benefits, and applications of the , with a focus on its ability to engrave tumblers and cut acrylic sheets.

The Basics of Fiber Optic Laser Cutters

A fiber optic laser cutter is a cutting-edge tool that uses laser beams guided through optical fibers to perform precise cuts or engravings. Unlike traditional laser systems, the fiber optic design allows for greater flexibility and accuracy. The laser beam is generated by a high-powered laser source, which is then transmitted through fiber optic cables to the cutting head.

This setup offers several advantages, including:

- High precision: Fiber optic lasers can achieve intricate details with minimal error margins.

- Speed: The laser beam operates at high speeds, making it ideal for large-scale projects.

- Versatility: It can work on a variety of materials, including glass, acrylic, and metal.

The is particularly popular for engraving tumblers and cutting acrylic sheets due to its ability to handle delicate materials without causing thermal damage.

Key Features of the Fiber Optic Laser Cutter

The boasts several features that set it apart from traditional laser engravers:

- Fiber Optic Delivery System: The use of optical fibers ensures that the laser beam is transmitted with minimal loss, allowing for precise cutting and engraving.

- Adjustable Power Settings: Operators can adjust the laser’s power to suit different materials and project requirements.

- User-Friendly Interface: Most models come with intuitive software that simplifies design uploads and adjustments.

- High-Speed Processing: The cutter operates at high speeds, reducing production time while maintaining quality.

These features make the a favorite among artists, craftsmen, and industrial manufacturers.

Applications of the Fiber Optic Laser Cutter

The versatility of the makes it suitable for a wide range of applications:

- Engraving Tumblers: Create personalized designs, logos, or patterns on tumblers with exceptional clarity and detail.

- Cutting Acrylic Sheets: Produce custom acrylic signs, displays, and decorative items with smooth edges and no burn marks.

- Custom Engraving: Design unique jewelry, name tags, or promotional items with intricate laser engravings.

- Sign Making: Create professional-grade signs for businesses, retail stores, and public spaces.

The ability to work on multiple materials makes the a valuable tool for both small-scale artisans and large-scale manufacturers.

Advantages of Using a Fiber Optic Laser Cutter

Switching to a offers numerous benefits over traditional cutting and engraving methods:

- Increased Efficiency: The high-speed operation reduces production time, allowing for faster turnaround on projects.

- Improved Precision: Fiber optic lasers can achieve detailed engravings with minimal error, ensuring consistent quality.

- Versatility: Capable of working on various materials, the cutter adapts to different project needs without compromising performance.

- Cost-Effective: Despite the initial investment, the long-term savings from reduced material waste and faster production make it a worthwhile choice.

These advantages highlight why the is becoming a standard tool in many industries.

Maintenance and Safety Considerations

Like any high-tech equipment, the requires proper maintenance to ensure optimal performance and longevity:

- Regular Cleaning: Dust and debris can accumulate on the laser head, affecting precision. Regular cleaning with a soft cloth is essential.

- Lubrication: Moving parts should be lubricated as per the manufacturer’s instructions to prevent wear and tear.

- Safety Precautions: Operators must wear protective eyewear and follow safety protocols to avoid laser exposure.

By adhering to maintenance guidelines, users can maximize the lifespan of their and ensure safe operation.

Frequently Asked Questions

Can the fiber optic laser cutter be used for metal engraving?

Yes, the can engrave metals with appropriate settings and materials. However, it’s important to use compatible materials to avoid damage to the machine.

What is the maximum thickness of acrylic that can be cut?

The maximum thickness depends on the model and power output of the cutter. Most models can handle acrylic sheets up to 20mm thick, but it’s always best to check the specifications.

Conclusion

The is a powerful tool that combines precision, speed, and versatility to meet the needs of modern engraving and cutting applications. Whether you’re creating personalized tumblers or intricate acrylic designs, this machine delivers exceptional results with minimal effort.

If you’re looking for a reliable solution for your engraving projects, consider investing in a . Its benefits far outweigh the initial costs, making it a worthwhile addition to any workshop or manufacturing facility.

Ready to take your projects to the next level? Explore the features and specifications of the today!