The Ultimate Guide to Laser Wood Cutter Machines: Precision, Efficiency, and Creativity at Your Fingertips

Laser wood cutter machines have revolutionized the way we approach woodworking projects. Whether you’re a professional craftsman or an enthusiastic hobbyist, these machines offer unparalleled precision, versatility, and efficiency. If you’re wondering how to bring your creative visions to life with intricate designs and seamless cuts, this article will guide you through everything you need to know about laser wood cutter machines.

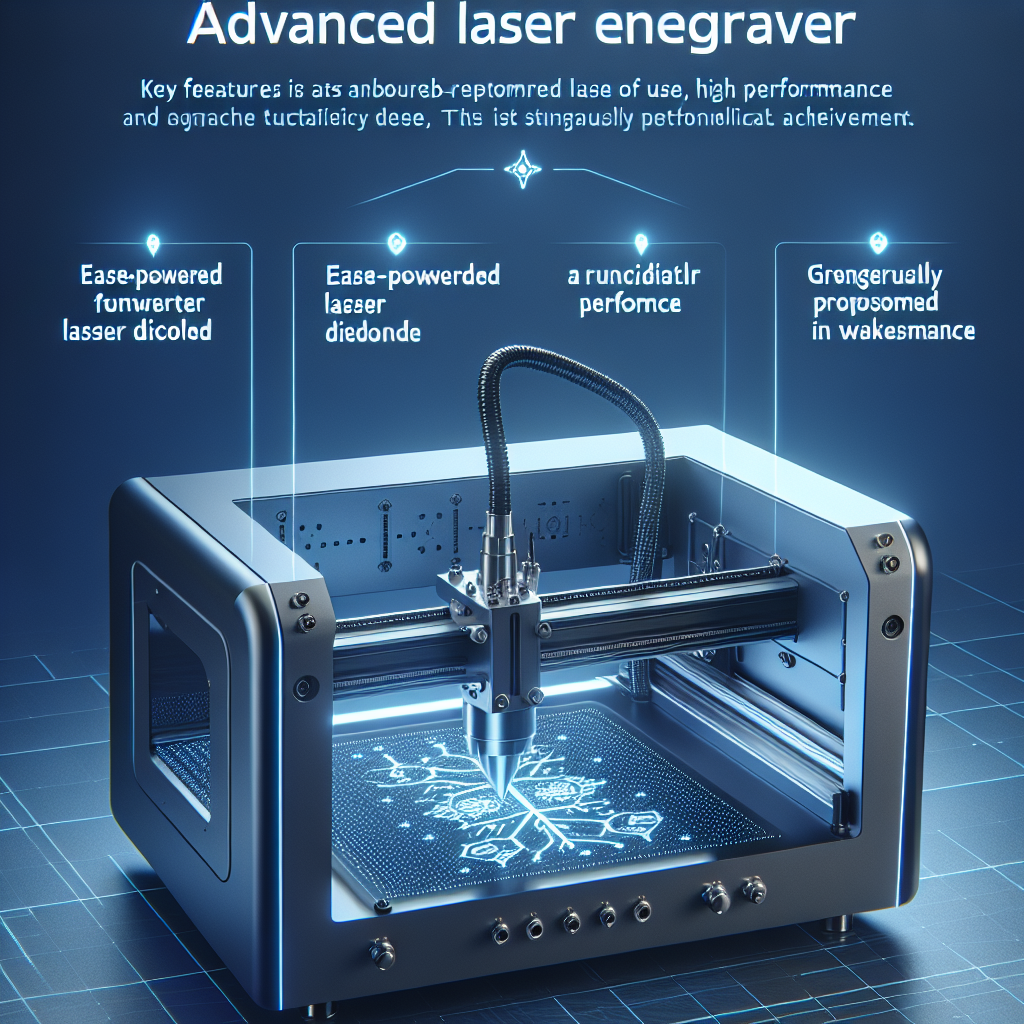

What is a Laser Wood Cutter Machine?

A laser wood cutter machine is a precision tool designed to cut, engrave, or etch materials such as wood, metal, plastic, and more. Unlike traditional cutting tools, these machines use a high-powered laser beam to produce clean, precise cuts with minimal material waste. The process involves directing the laser beam through a focused lens, which heats the material to its melting point, effectively vaporizing it and creating intricate designs or patterns.

These machines are ideal for both small-scale projects and large-scale production. They are widely used in industries such as furniture making, signage creation, decorative arts, and even custom gift-making. With a laser wood cutter machine, you can achieve professional-quality results from the comfort of your home or workshop.

Key Features and Benefits

Before diving into how these machines work, it’s essential to understand their key features and benefits:

- Precision Cutting: Laser wood cutter machines provide exceptional accuracy, allowing for intricate designs and tight tolerances.

- Customization: You can create unique patterns, logos, or text using design software, making it easy to personalize your projects.

- Versatility: These machines are compatible with a wide range of materials, including wood, acrylic, leather, and even some metals.

- Efficiency: Laser cutting is faster than traditional methods, reducing production time and increasing output.

- Safety: Modern laser cutters are equipped with safety features to protect users from harmful emissions and ensure safe operation.

If you’re someone who values precision and creativity, a laser wood cutter machine is an invaluable addition to your toolkit. But how exactly does it work? Let’s explore the mechanics behind this innovative technology.

How Does a Laser Wood Cutter Machine Work?

The operation of a laser wood cutter machine involves several key components working together to produce precise cuts and engravings. Here’s a breakdown of the process:

- Laser Source: The heart of the machine is the laser source, which generates a focused beam of light energy.

- Focusing Lens: The laser beam passes through a lens that concentrates it into a tiny spot, increasing its intensity.

- Cutting Head: The cutting head moves across the material, directing the laser beam to follow the programmed design or pattern.

- Control System: Advanced software controls the movement of the cutting head and ensures precise execution of the design.

The machine operates by vaporizing the material along the designated cut line. This process is clean, fast, and produces minimal waste compared to traditional cutting methods. It’s also worth noting that modern machines often come with user-friendly interfaces, making them accessible even for those without extensive technical expertise.

Top Uses for Your Laser Wood Cutter Machine

One of the most appealing aspects of a laser wood cutter machine is its versatility. Here are some popular applications:

- Furniture Making: Create custom furniture with intricate details and seamless joints.

- Signage Creation: Design eye-catching signs, plaques, or decorative panels with precision engravings.

- Custom Gifts: Produce personalized items such as engraved wooden boxes, picture frames, or coasters.

- Decorative Arts: Craft intricate wood art pieces, wall hangings, and other decorative items.

If you’re looking to expand your creative horizons or enhance your business offerings, a laser wood cutter machine is an excellent investment. But how do you choose the right one for your needs?

Choosing the Right Laser Wood Cutter Machine

With so many options available on the market, selecting the perfect laser wood cutter machine can be overwhelming. Here are some factors to consider:

- Type of Material: Determine what materials you’ll primarily work with. Some machines are optimized for specific materials, while others offer multi-material compatibility.

- Power Output: Higher power output enables faster cutting and engraving, but it may also increase costs. Consider your project requirements when choosing the right power level.

- Software Compatibility: Ensure that the machine is compatible with your preferred design software to maximize workflow efficiency.

For those seeking a high-quality, versatile option, the [insert product name] laser wood cutter machine is an excellent choice. It combines powerful performance with user-friendly features, making it suitable for both beginners and seasoned professionals.

Maintenance and Safety Tips

To get the most out of your laser wood cutter machine, proper maintenance and adherence to safety guidelines are essential:

- Cleanliness: Regularly clean the machine to prevent dust buildup, which can interfere with laser performance.

- Lens Care: Keep the focusing lens free from scratches and contaminants to maintain optimal cutting precision.

- Ventilation: Ensure adequate ventilation in your workspace to avoid inhaling harmful fumes produced during the cutting process.

By following these simple maintenance tips, you can extend the lifespan of your machine and ensure consistent performance for years to come.

Frequently Asked Questions

If you’re new to laser wood cutter machines, here are some common questions you might have:

- How expensive are laser wood cutter machines? Prices vary depending on the features and power output. Entry-level models can start at around $1,000, while high-end professional units may cost upwards of $5,000.

- Can I use it for materials other than wood? Yes! Many laser cutters are compatible with a wide range of materials, including acrylic, leather, and even some metals.

- Is it difficult to learn how to use one? Most machines come with user-friendly interfaces and software, making them accessible for beginners. However, familiarizing yourself with the controls and safety guidelines is essential before starting your first project.

Conclusion

A laser wood cutter machine is a game-changer for anyone looking to elevate their woodworking projects or start a new creative venture. Its precision, versatility, and efficiency make it an invaluable tool in any workshop. Whether you’re crafting custom furniture, creating decorative art, or producing signage, this machine has the potential to transform your creative process.

If you’re ready to take your woodworking skills to the next level, consider investing in a high-quality laser wood cutter machine like the [insert product name]. With proper care and technique, it will serve as a reliable companion for all your future projects.

Have you used a laser wood cutter machine before? Let us know about your experiences or any questions you have in the comments below!