Laser Engraving: Precision, Artistry, and Versatility in Modern Manufacturing

Laser engraving has revolutionized the way we create intricate designs, patterns, and text on various materials. It is a process that combines precision, efficiency, and creativity, making it an indispensable tool in industries ranging from manufacturing to jewelry design. If you’re considering is particularly popular due to its durability and aesthetic appeal. Whether you’re creating custom jewelry, decorative items, or industrial components, laser engraving provides a versatile solution.

Applications of Laser Engraving

Laser engraving has found applications in numerous industries. Here are some of the most common uses:

- Jewelry Design: Creating intricate patterns and personalized engravings on precious metals like gold, silver, and platinum.

- Industrial Manufacturing: Marking serial numbers, barcodes, and logos on machinery parts for identification and traceability.

- Furniture and Decor: Adding decorative elements to wood, glass, or metal surfaces for a luxurious finish.

- Medical Devices: Engraving detailed markings on surgical instruments and implants for precision and safety.

- Crafts and Art: Producing custom designs, logos, and text on various materials for artistic purposes.

The versatility of laser engraving makes it suitable for both small-scale projects and large industrial operations. For example, a small laser engraver can handle intricate details on jewelry, while larger machines are ideal for mass production in manufacturing.

Advantages of Laser Engraving Over Traditional Methods

Compared to traditional engraving methods, laser engraving offers several advantages:

- Precision and Accuracy: The focused laser beam ensures that even the most intricate designs are engraved with pinpoint accuracy. This is especially important in industries like jewelry design, where every detail matters.

- Speed and Efficiency: Laser engraving machines can complete tasks much faster than manual methods, reducing production time and costs.

- Versatility: The ability to work on multiple materials and create a wide range of designs makes laser engraving adaptable to various applications.

- Durability: Engravings created by lasers are permanent and resistant to fading or wear, ensuring long-lasting results.

- Eco-Friendly: Laser engraving produces minimal waste compared to traditional methods that involve cutting or drilling materials.

These advantages make laser engraving a preferred choice for businesses looking to enhance their production capabilities while maintaining high standards of quality and efficiency.

Choosing the Right Laser Engraving Equipment

Selecting the appropriate laser engraving machine is crucial to achieving optimal results. Factors to consider include:

- Type of Material: Different materials require different laser settings. For example, metal requires a higher-powered laser compared to wood or plastic.

- Project Size: Determine whether you need a small laser engraver for detailed work or a larger machine for industrial-scale production.

- Budget: Laser engraving machines vary in price depending on their size, power, and features. Choose one that fits your budget while meeting your project requirements.

- User-Friendliness: Look for machines with intuitive software interfaces and easy-to-use controls to ensure a smooth learning curve.

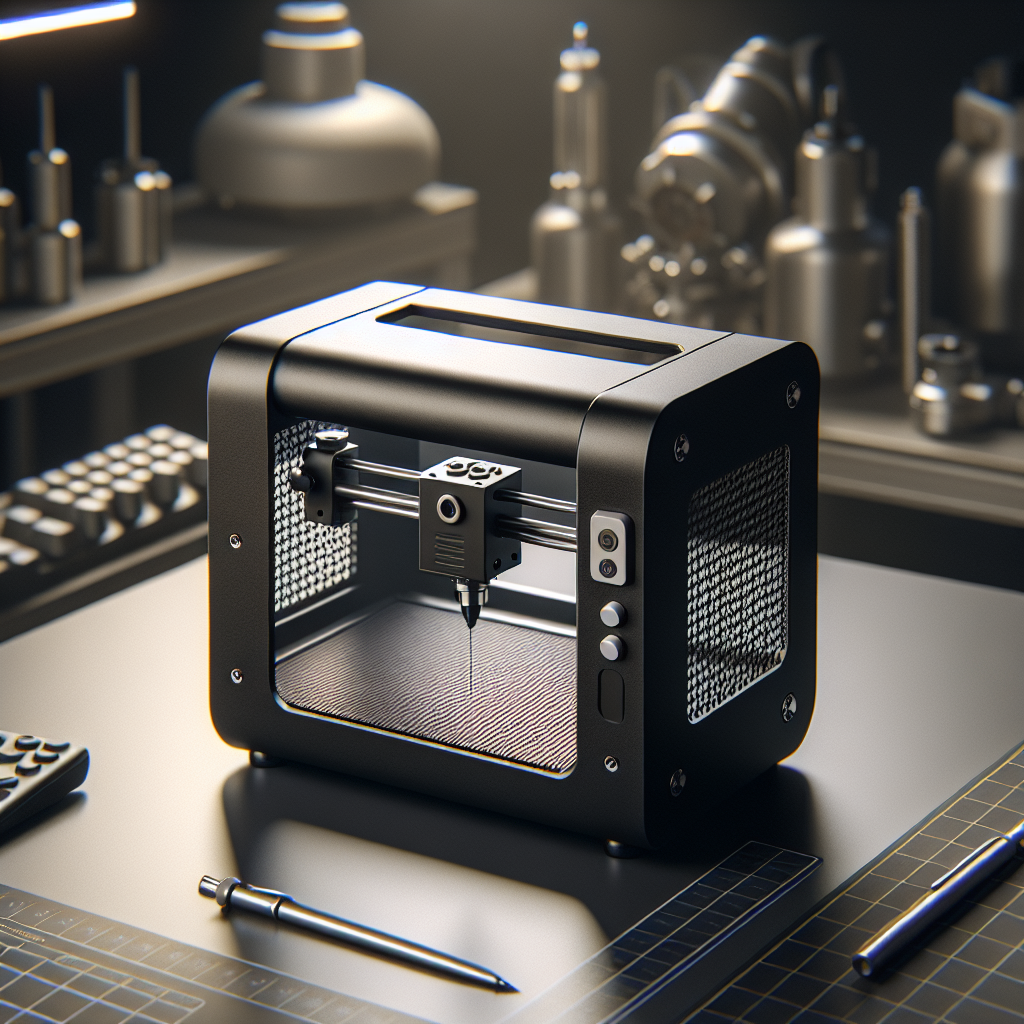

If you’re starting out or working on small-scale projects, a compact machine like the metal laser engraving small laser engraver can be an excellent investment. It offers high precision and versatility without breaking the bank.

Tips for Getting Started with Laser Engraving

If you’re new to laser engraving, here are some tips to help you get started:

- Start Small: Begin with simple designs to familiarize yourself with the machine and its settings.

- Experiment with Materials: Test different materials to understand how they react to laser engraving and adjust your settings accordingly.

- Use Proper Safety Gear: Laser engraving involves high-intensity light, so wear protective eyewear and ensure the machine is operated in a well-ventilated area.

- Invest in Quality Software: Good design software can enhance your creativity and simplify the engraving process.

By following these tips and investing in the right equipment, you can unlock the full potential of laser engraving and create stunning, high-quality designs for various applications.

Frequently Asked Questions About Laser Engraving

1. Can I use a small laser engraver for industrial purposes?

While small laser engravers are ideal for detailed work, they may not be suitable for large-scale industrial production due to their limited power and capacity.

2. Is laser engraving safe?

Yes, provided you follow safety guidelines and use appropriate protective gear. The focused laser beam can cause eye injuries if not handled properly, so always prioritize safety.

3. How long does it take to learn laser engraving?

The learning curve depends on your prior experience with design software and machinery. With practice, you can master the basics in a few weeks.

4. Can I engrave all types of metals?

Yes, most metals can be engraved using laser technology. However, the power settings may need to be adjusted depending on the metal’s hardness and thickness.

Conclusion

Laser engraving is a powerful tool that has transformed the way we create and customize products. Its precision, versatility, and efficiency make it an excellent choice for both small-scale artisans and large industrial manufacturers. By understanding its applications, advantages, and choosing the right equipment, you can harness the full potential of laser engraving to bring your creative visions to life.

If you’re ready to take the plunge into the world of laser engraving, consider investing in a reliable machine like the metal laser engraving small laser engraver. With proper technique and practice, you’ll be creating stunning engravings in no time!