Laser Machine Engraving Cutting: A Comprehensive Guide

Welcome to the fascinating world of laser machine engraving cutting. In this article, we will explore everything you need to know about this innovative technology, its applications, benefits, and how you can integrate it into your projects. Whether you’re a hobbyist, artist, or business owner, understanding laser machines can open up endless possibilities for precision and creativity.

What is Laser Engraving Cutting?

Laser engraving cutting involves using high-powered laser beams to etch intricate designs onto various materials. Unlike traditional methods that use mechanical tools, this process offers unparalleled precision and versatility. The machine emits a focused beam of light that vaporizes or melts the material’s surface, creating permanent marks or cuts. This method is widely used in industries such as woodworking, metal fabrication, jewelry making, and even electronics.

One common question is: “What materials can be engraved with a laser machine?” The answer is almost countless! From wood and acrylic to metals like stainless steel and aluminum, laser machines are incredibly adaptable. They can also handle glass, stone, and plastics, making them a versatile tool for various applications.

How Does Laser Engraving Cutting Work?

The process begins with designing your artwork using specialized software. Once the design is ready, it’s sent to the laser machine via a computer interface. The machine then reads the design and translates it into precise movements of the laser beam. This beam heats the material to extremely high temperatures, either cutting through or leaving an engraved mark.

One key advantage of this method is its ability to achieve microscopic precision. Even intricate patterns with tiny details can be reproduced accurately. For instance, wedding rings or custom trophies often require such detail, which traditional methods struggle to match.

Applications of Laser Engraving Cutting

Laser machines have revolutionized numerous industries. Here are some common applications:

- Custom Engraving: Personalized items like name tags, plaques, and gifts.

- Cutouts: Creating shapes in materials for signs, decorative pieces, or functional parts.

- Metal Processing: Etching logos on tools or cutting metal sheets for prototypes.

- Fabrication: Precise cutting of materials for manufacturing components.

A frequently asked question is: “Can laser machines be used for both engraving and cutting?” Absolutely! Many modern machines, like the , are designed to handle both tasks seamlessly.

Advantages of Laser Engraving Cutting

The benefits of using laser machines are manifold:

- Precision: Achieve exact cuts and engravings, even on complex designs.

- Versatility: Works with a wide range of materials, from thin sheets to thick blocks.

- Speed: Processes can be completed much faster than manual methods.

- Durability: The engraved marks are permanent and resistant to wear.

Additionally, laser machines minimize waste compared to traditional cutting methods. For example, when creating a sign with intricate lettering, the machine only removes the necessary material, preserving the rest for future use.

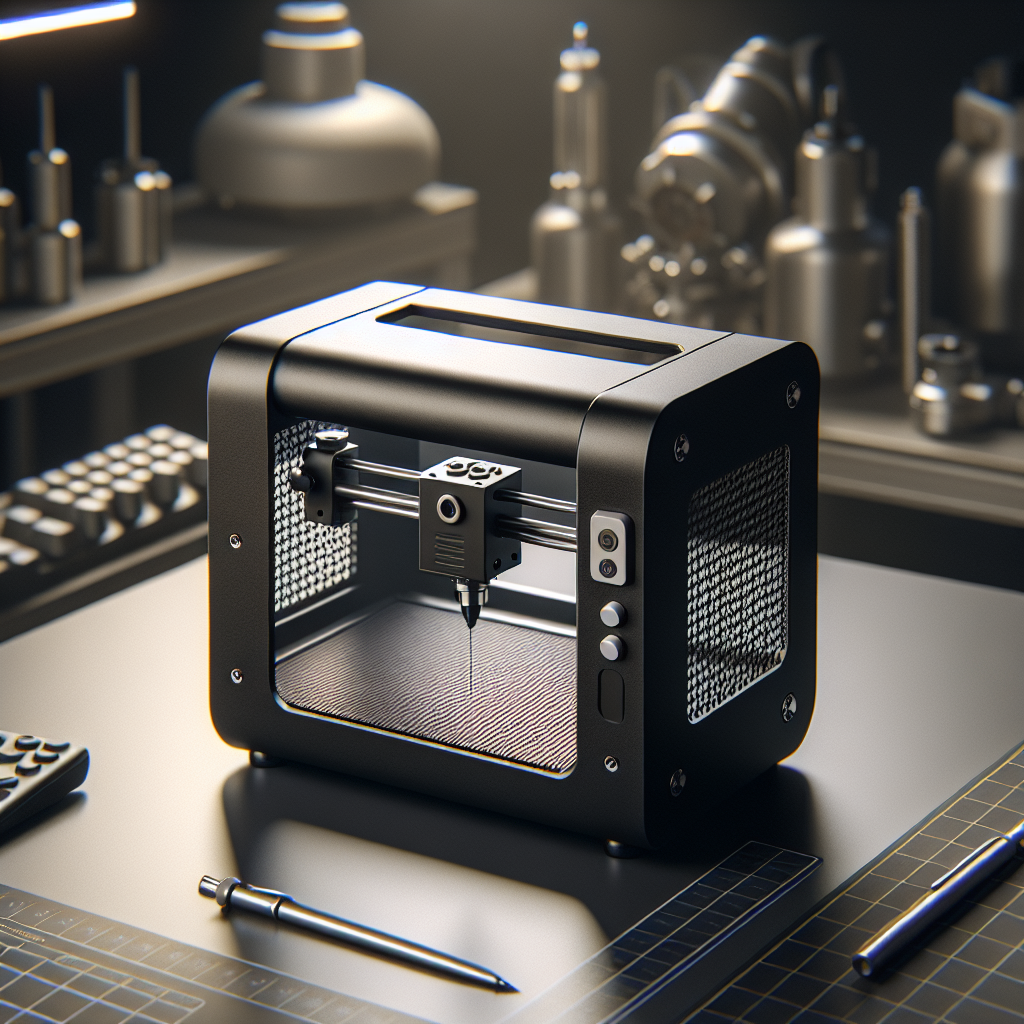

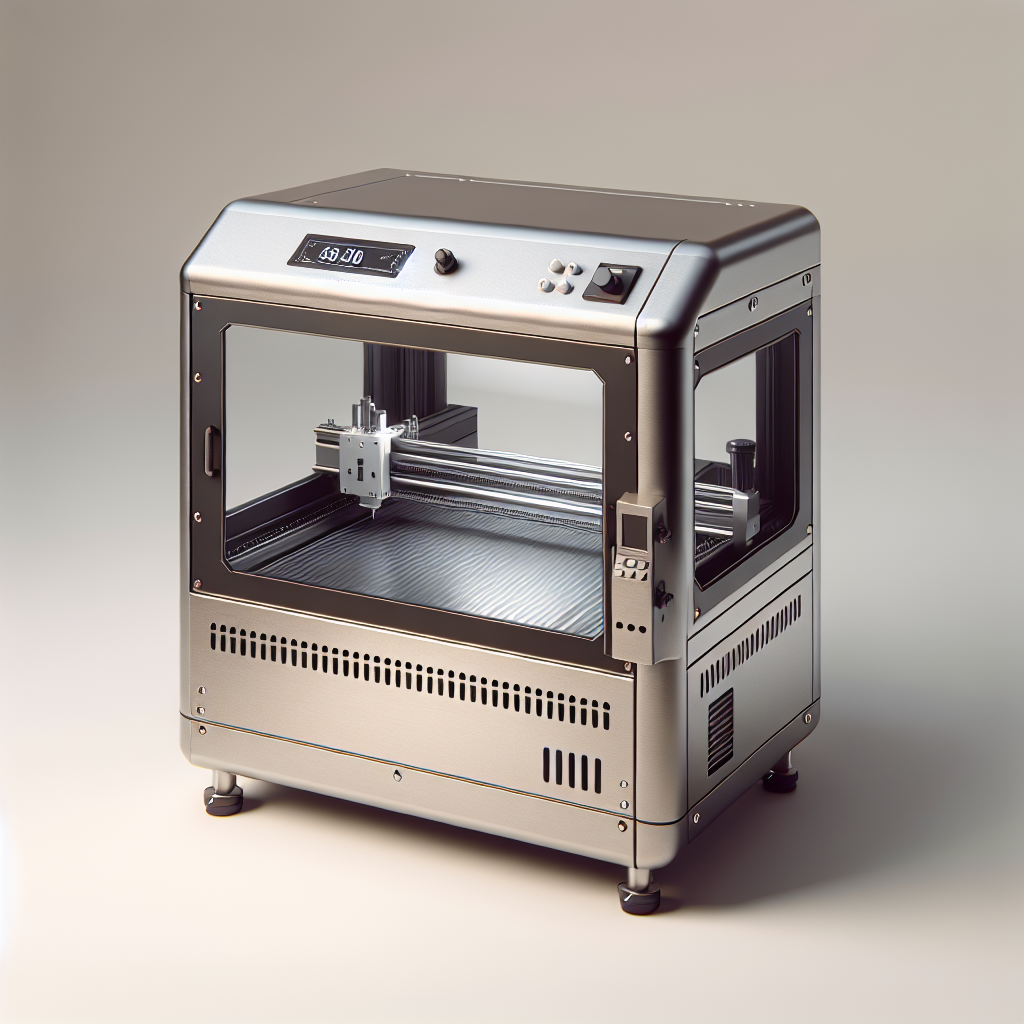

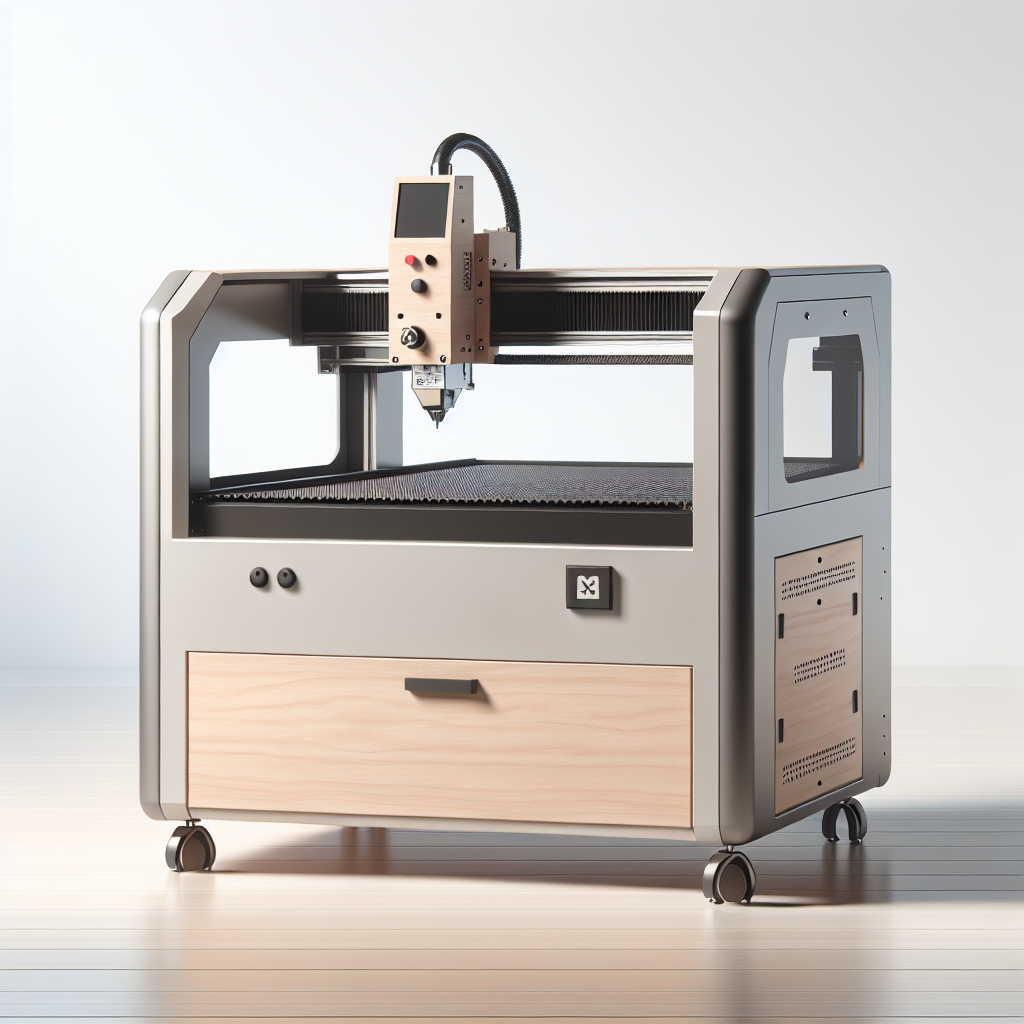

Choosing the Right Laser Engraving Cutting Machine

Selecting the appropriate machine depends on your specific needs and budget. Key factors to consider include:

- Power Output: Higher wattage machines are better suited for thicker materials like metal.

- Focal Length: Determines how tightly the laser beam is focused, affecting precision.

- Software Compatibility: Ensure it supports your design programs to maintain workflow efficiency.

A common concern is: “What’s the best machine for small-scale projects?” The laser machine engraving cutting