The Ultimate Guide to Laser Cutter Machines for Wood

Welcome to our comprehensive guide on laser cutter machines for wood! If you’re exploring the world of precision woodworking or custom design projects, this article will provide you with all the essential information you need. From understanding how these machines work to choosing the right one for your needs, we’ve got you covered.

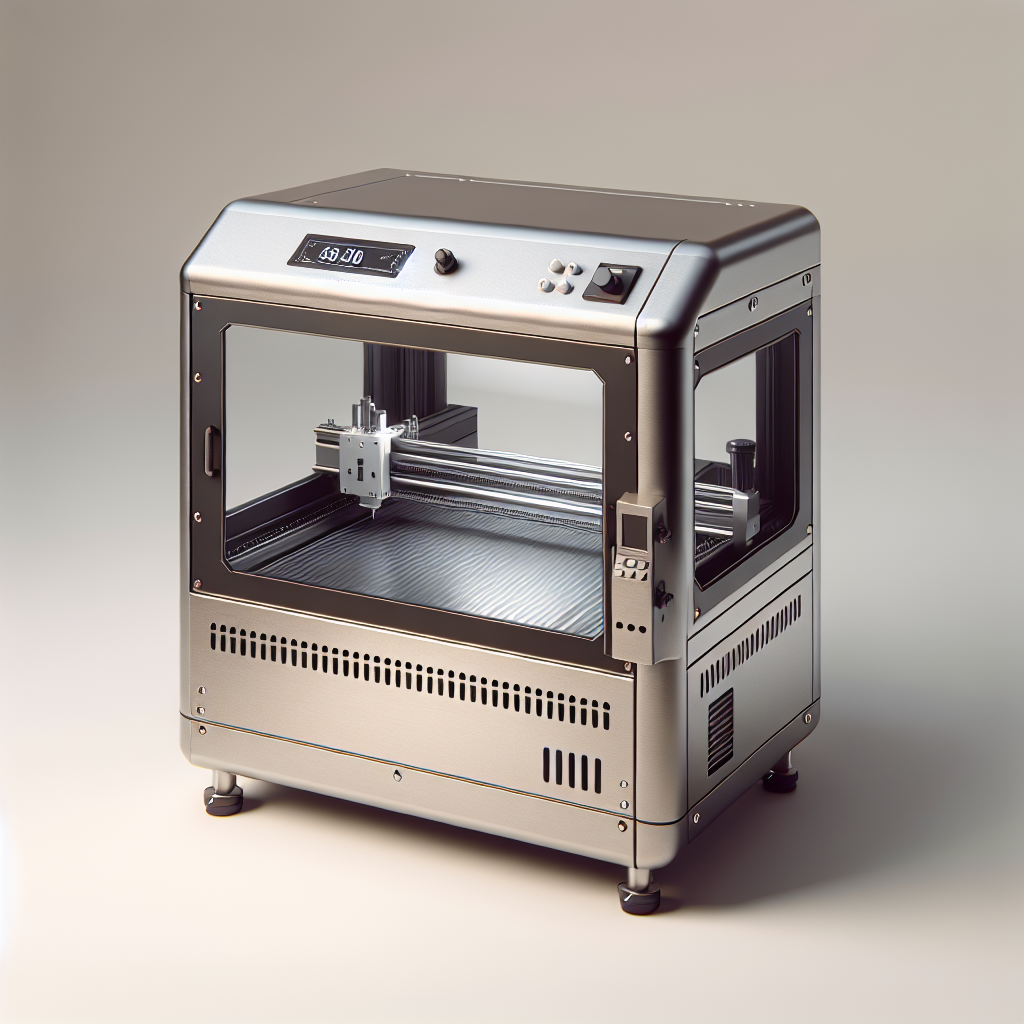

What is a Laser Cutter Machine for Wood?

A laser cutter machine for wood is a cutting-edge tool designed to precisely cut and engrave wooden materials with exceptional accuracy. Unlike traditional woodworking tools, laser cutters use a focused beam of light to make intricate cuts, enabling detailed and complex designs that are difficult to achieve manually. These machines are widely used in various applications, including furniture making, signage creation, and artistic projects.

One of the standout features of these machines is their ability to work with different types of wood, from hardwoods like oak to softwoods like pine. This versatility makes them a valuable addition for both professionals and hobbyists alike.

Benefits of Using a Laser Cutter Machine for Wood

Investing in a laser cutter machine for wood offers numerous benefits that can significantly enhance your woodworking projects:

- Precision Cutting: Achieve intricate details and sharp edges with minimal material waste.

- Speed: Cut through wood quickly, saving time compared to manual methods.

- Customization: Create unique designs and patterns that are impossible with traditional tools.

- Safety: Reduced risk of injury compared to using power tools manually.

- Versatility: Suitable for a wide range of projects, from small decorative items to large-scale furniture pieces.

These benefits make laser cutter machines an indispensable tool in modern woodworking.

How Does a Laser Cutter Machine Work?

A laser cutter machine operates by directing a high-powered laser beam at the material being cut. The laser heats and vaporizes the wood, creating precise cuts along pre-designed patterns. Here’s a simplified breakdown of the process:

- Design: Create your design using computer-aided design (CAD) software.

- Engraving/Cutting: The laser follows the design, cutting or engraving the wood as programmed.

- Finishing: Post-processing steps like sanding and staining complete the project.

This process ensures that every cut is accurate and consistent, enhancing the quality of your finished product.

Choosing the Right Laser Cutter Machine for Your Needs

Selecting the right laser cutter machine involves considering several factors:

- Power Output: Higher wattage lasers handle thicker materials but may be overkill for thinner wood.

- Size: Consider the size of your workspace and the scale of projects you undertake.

- Budget: Determine your budget, as machines vary widely in price based on features and power.

For example, the is a popular choice for its balance of power and affordability. It’s perfect for both small-scale projects and more ambitious endeavors.

Maintenance and Safety Tips

To ensure optimal performance and longevity, proper maintenance is essential:

- Cleanliness: Regularly clean the machine to prevent dust buildup, which can affect laser performance.

- Lens Care: Keep the focusing lens free from contaminants to maintain cutting accuracy.

- Regular Checks: Inspect belts, mirrors, and other components for wear and tear.

Safety should always be a priority. Use protective eyewear and ensure adequate ventilation when operating the machine, as laser cutting produces fumes and particles.

FAQs about Laser Cutter Machines for Wood

Here are answers to some common questions:

- How easy is it to learn to use a laser cutter?

Most machines come with user-friendly software, making them accessible even for beginners. Practice on scrap wood to build skills. - Can I cut different materials besides wood?

Yes! Many laser cutters can handle materials like acrylic, plastic, and metal, expanding their versatility.

Conclusion

A laser cutter machine for wood is a transformative tool that combines precision with creativity. Whether you’re crafting intricate designs or producing large-scale furniture, these machines offer unmatched capabilities. By understanding how they work, the benefits they provide, and how to choose the right one, you can elevate your woodworking projects to new heights.

Ready to take the plunge? Explore our recommended models like the , designed to meet a variety of needs. Happy crafting!