The Ultimate Guide to Acrylic Laser Cutters: Precision Meets Creativity

Are you looking for a versatile tool that can transform your creative projects into reality? If so, an acrylic laser cutter might be the perfect solution for you. This innovative device is designed to cut and engrave intricate designs on various materials with precision and ease. In this article, we will explore everything you need to know about acrylic laser cutters, including their benefits, applications, and how they work. By the end of this guide, you’ll be equipped with the knowledge to decide if an acrylic laser cutter is right for your needs.

What Is an Acrylic Laser Cutter?

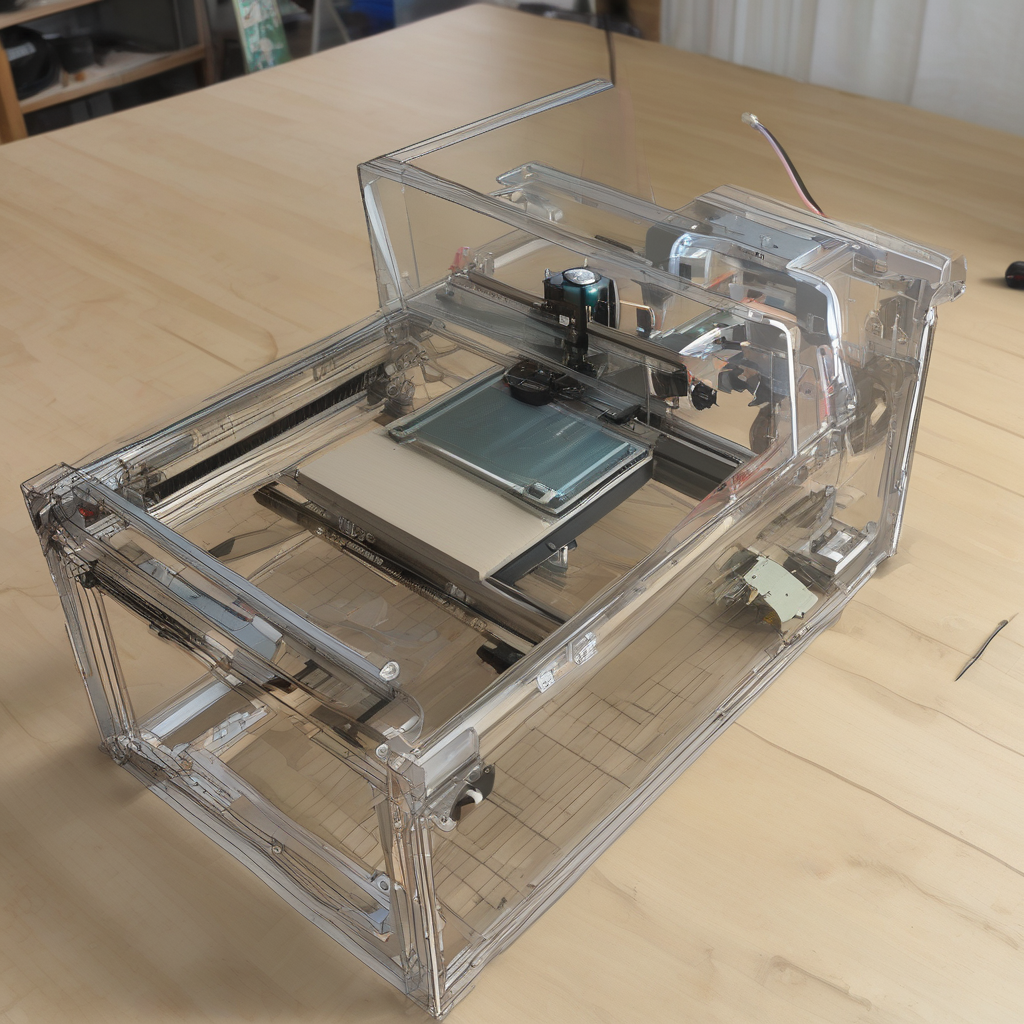

An acrylic laser cutter is a precision tool that uses a focused laser beam to cut and engrave materials such as acrylic, wood, metal, and more. Unlike traditional cutting methods, which often require physical contact with the material, laser cutting is non-contact, resulting in cleaner cuts and less wear and tear on the equipment. The process involves directing a high-powered laser at the material, where the intense heat melts or vaporizes the material along the programmed design.

The device typically comes with user-friendly software that allows you to upload designs, adjust settings, and preview the final result before cutting. This makes it accessible even for those who are new to laser cutting technology. Whether you’re a hobbyist, DIY enthusiast, or a professional artist, an acrylic laser cutter can be a valuable addition to your toolkit.

Why Choose an Acrylic Laser Cutter?

There are numerous reasons why an acrylic laser cutter is a popular choice among creators and manufacturers. Let’s explore some of the key benefits:

- Precision and Accuracy: The laser beam can create extremely fine details, making it ideal for intricate designs.

- Versatility: It works with a wide range of materials, including acrylic, wood, metal, plastic, and leather.

- Speed: Once the design is programmed, the cutting process is fast and efficient.

- Cost-Effective: Minimal material waste and reduced labor costs make it a cost-effective solution in the long run.

- Non-Contact Process: No physical wear on the material or machine, resulting in cleaner cuts and longer tool life.

If you’re wondering whether an acrylic laser cutter is suitable for your projects, consider the type of materials you work with and the level of detail required. For example, if you’re creating custom signs or decorative items, this tool can significantly enhance your output quality.

Applications of Acrylic Laser Cutters

The versatility of acrylic laser cutters makes them suitable for a wide range of applications across different industries. Here are some common uses:

- Signage and Advertising: Creating custom signs, logos, and lettering with precision.

- Furniture Making: Cutting intricate designs into wood or acrylic for decorative elements.

- Automotive Industry: Engraving parts or creating custom dashboards.

- Diy Projects: Crafting personalized gifts, home decor, and more.

- Fashion and Accessories: Cutting and engraving materials for jewelry, belts, and other accessories.

Whether you’re a professional artist or a hobbyist, an acrylic laser cutter can help bring your creative visions to life. Its ability to handle various materials and create detailed designs makes it a must-have tool for many projects.

How Does an Acrylic Laser Cutter Work?

To understand how an acrylic laser cutter works, let’s break down the process step by step:

- Material Preparation: The material is placed on a bed or surface. For acrylic, it’s essential to ensure it’s clean and free from any contaminants that could affect the cutting process.

- Design Upload: The design is created using computer-aided design (CAD) software or other compatible programs. This design is then uploaded to the laser cutter’s control system.

- Laser Cutting Process: The laser beam, directed by mirrors and lenses, follows the programmed design to melt, burn, or vaporize the material along the designated path.

- Finishing Touches: After the cutting process is complete, any excess material or residue is removed, leaving a smooth and polished finish.

The precision of the laser ensures that even complex designs can be executed with ease. This makes it an ideal choice for both small-scale projects and large-scale manufacturing processes.

Choosing the Right Acrylic Laser Cutter

With so many options available, selecting the right acrylic laser cutter can feel overwhelming. Here are some factors to consider when making your decision:

- Power Level: Higher power levels are generally better for cutting thicker materials or engraving harder surfaces.

- Software Compatibility: Ensure the laser cutter is compatible with the software you plan to use for designing and programming your projects.

- Size and Capacity: Consider the size of the machine and its cutting area. A larger bed might be necessary if you’re working on bigger projects.

- Budget: Determine how much you’re willing to spend, as prices vary based on power, features, and brand.

If you’re still unsure about which model to choose, consider reading reviews or consulting with experts in the field. This can help you make an informed decision that aligns with your specific needs.

Maintenance and Safety Tips

Like any precision tool, an acrylic laser cutter requires proper maintenance to ensure optimal performance and longevity. Here are some tips to keep your machine running smoothly:

- Cleanliness: Regularly clean the laser bed and optics to prevent dust or debris from affecting the cutting process.

- Calibration: Periodically check and adjust the alignment of the laser beam to maintain precision in cuts.

- Storage: Store the machine in a cool, dry place when not in use to prevent damage from humidity or temperature changes.

- Safety Precautions: Always follow safety guidelines, such as wearing protective eyewear and ensuring proper ventilation during operation.

By taking care of your acrylic laser cutter, you can extend its lifespan and continue creating high-quality projects for years to come.

User Experiences and Feedback

To get a better sense of how acrylic laser cutters perform in real-world scenarios, let’s look at some user experiences:

“I’ve been using my acrylic laser cutter for over two years now, and it has completely transformed my DIY projects. The precision is unmatched, and the ease of use makes it accessible even for someone like me who isn’t very tech-savvy.” — Sarah, Hobbyist

“As a professional signmaker, I rely on my acrylic laser cutter to produce high-quality custom signs. It’s saved me countless hours compared to traditional methods and has significantly boosted my productivity.” — Michael, Signmaker

User feedback highlights the versatility and reliability of acrylic laser cutters across various applications. Whether you’re a hobbyist or a professional, this tool can be a valuable addition to your arsenal.

Conclusion

An acrylic laser cutter is an invaluable tool for anyone looking to create precise, detailed designs in a variety of materials. Its versatility, ease of use, and ability to handle both small and large-scale projects make it a favorite among artists, hobbyists, and professionals alike. By understanding how it works, selecting the right model, and maintaining it properly, you can unlock its full potential and bring your creative ideas to life.

If you’re ready to take your projects to the next level, consider investing in an acrylic laser cutter today. With its numerous benefits and wide range of applications, it’s sure to become a go-to tool in your workshop or studio.