The Evolution and Applications of Metal Laser Engraving Machines in Modern Industry

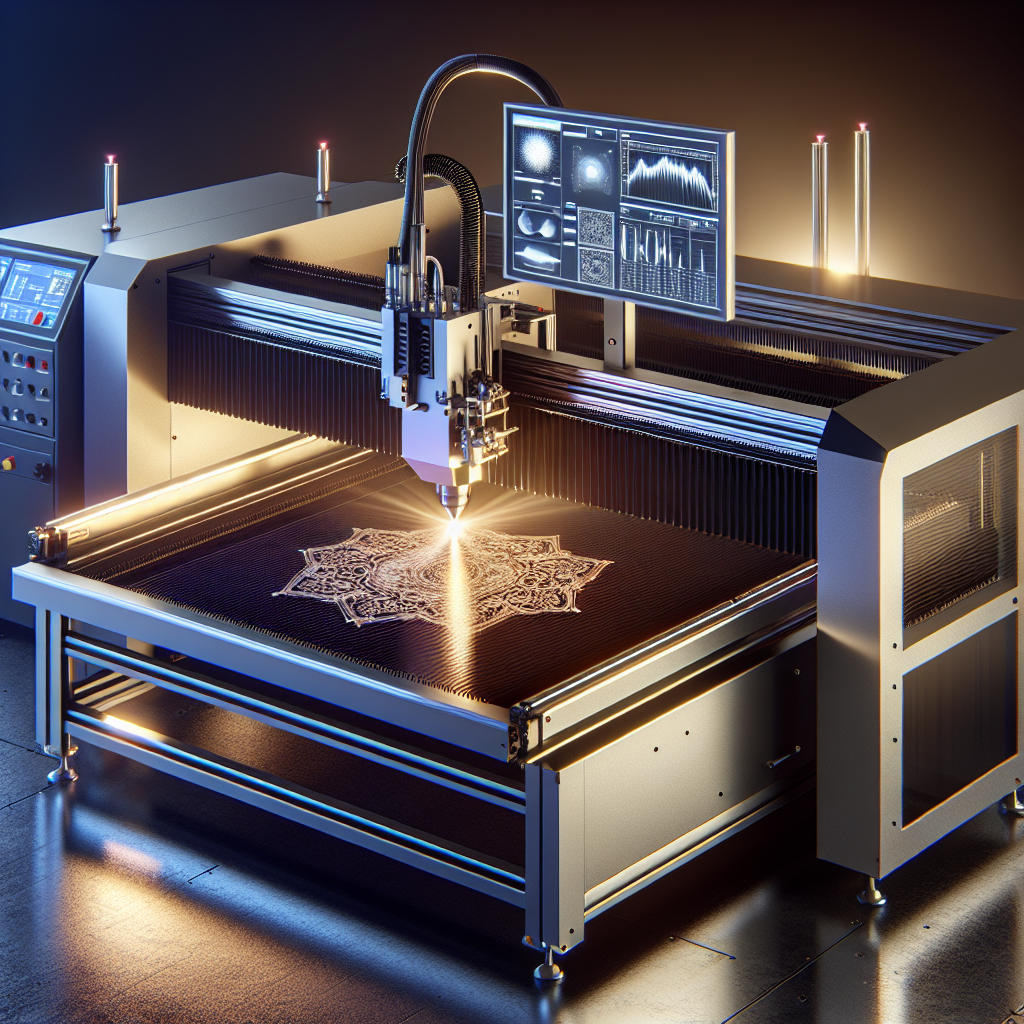

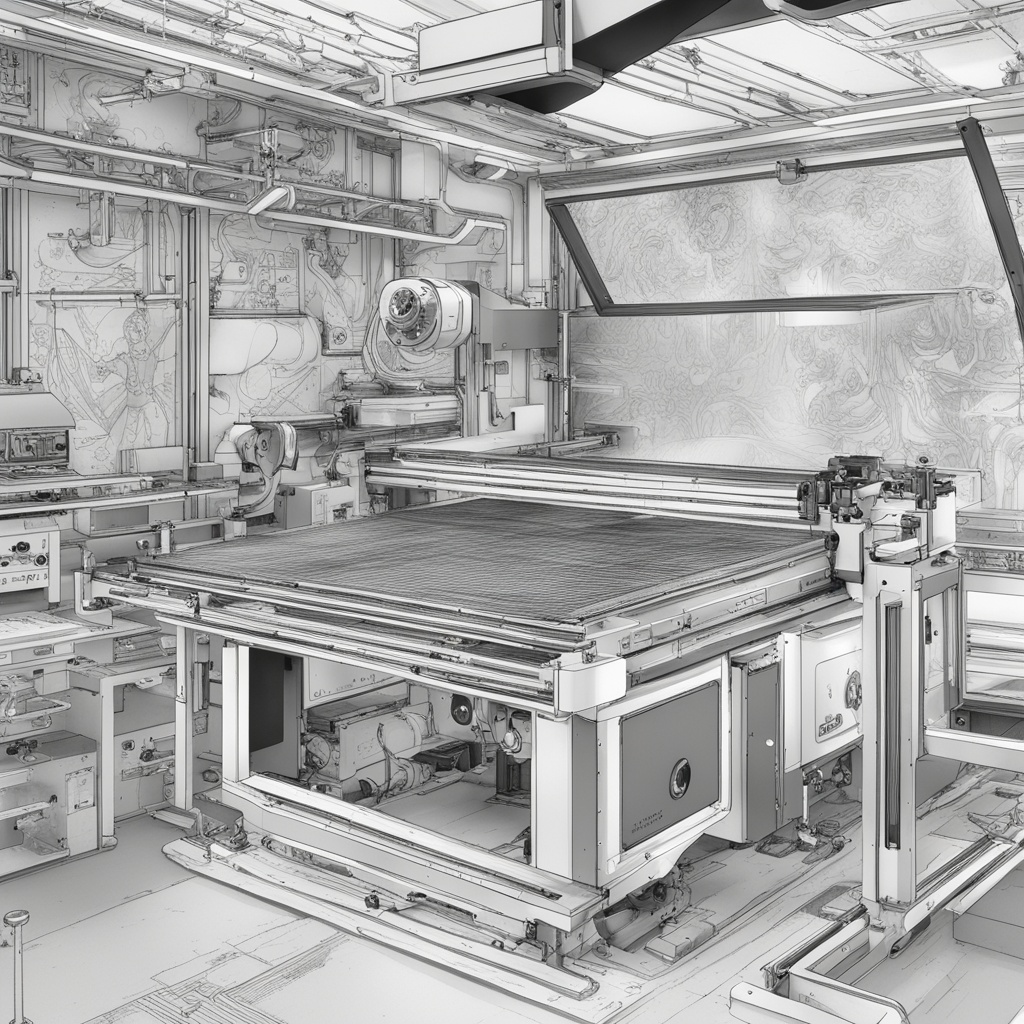

In the realm of precision manufacturing and customization, metal laser engraving machine systems have emerged as indispensable tools. These advanced devices combine cutting-edge laser technology with robust engineering to deliver unparalleled accuracy and efficiency. Whether for industrial production, artistic design, or functional part marking, metal laser engraving machines are transforming how businesses approach material processing.

How Do Metal Laser Engraving Machines Work?

At their core, metal laser engraving machine units operate by focusing a high-intensity laser beam onto a metal surface. This beam vaporizes or melts the material, creating permanent marks, patterns, or cuts. The process is controlled via computer software, ensuring micron-level precision even on complex geometries. Key components include:

- Laser Source: Typically fiber or CO2 lasers, optimized for metal interaction.

- Motion Control System: Guides the laser head across X, Y, and Z axes.

- Cooling System: Maintains optimal operating temperatures.

- Software Interface: Converts designs into machine-readable instructions.

Why is this technology preferred over traditional methods? Unlike mechanical engraving, metal laser engraving machine systems eliminate tool wear, reduce material waste, and enable rapid prototyping.

Key Advantages of Using a Metal Laser Engraving Machine

Investing in a metal laser engraving machine offers businesses a competitive edge through:

- Precision: Achieve details as fine as 0.001 inches.

- Speed: Process complex designs in minutes.

- Versatility: Compatible with stainless steel, aluminum, titanium, and alloys.

- Durability: Laser marks resist fading, corrosion, and abrasion.

Did you know? Modern metal laser engraving machine models can even adjust power settings to create color contrasts on metals through oxidation effects.

Industries Revolutionized by Metal Laser Engraving Technology

From aerospace to jewelry design, metal laser engraving machine solutions are driving innovation:

- Medical Devices: Engrave surgical tools with traceability codes.

- Automotive: Mark VIN numbers and component IDs.

- Electronics: Create micro-scale circuit board labels.

- Art & Luxury Goods: Produce intricate decorative patterns.

What challenges do these industries face without laser engraving? Manual methods struggle with consistency, scalability, and compliance with strict regulatory standards.

Choosing the Right Metal Laser Engraving Machine

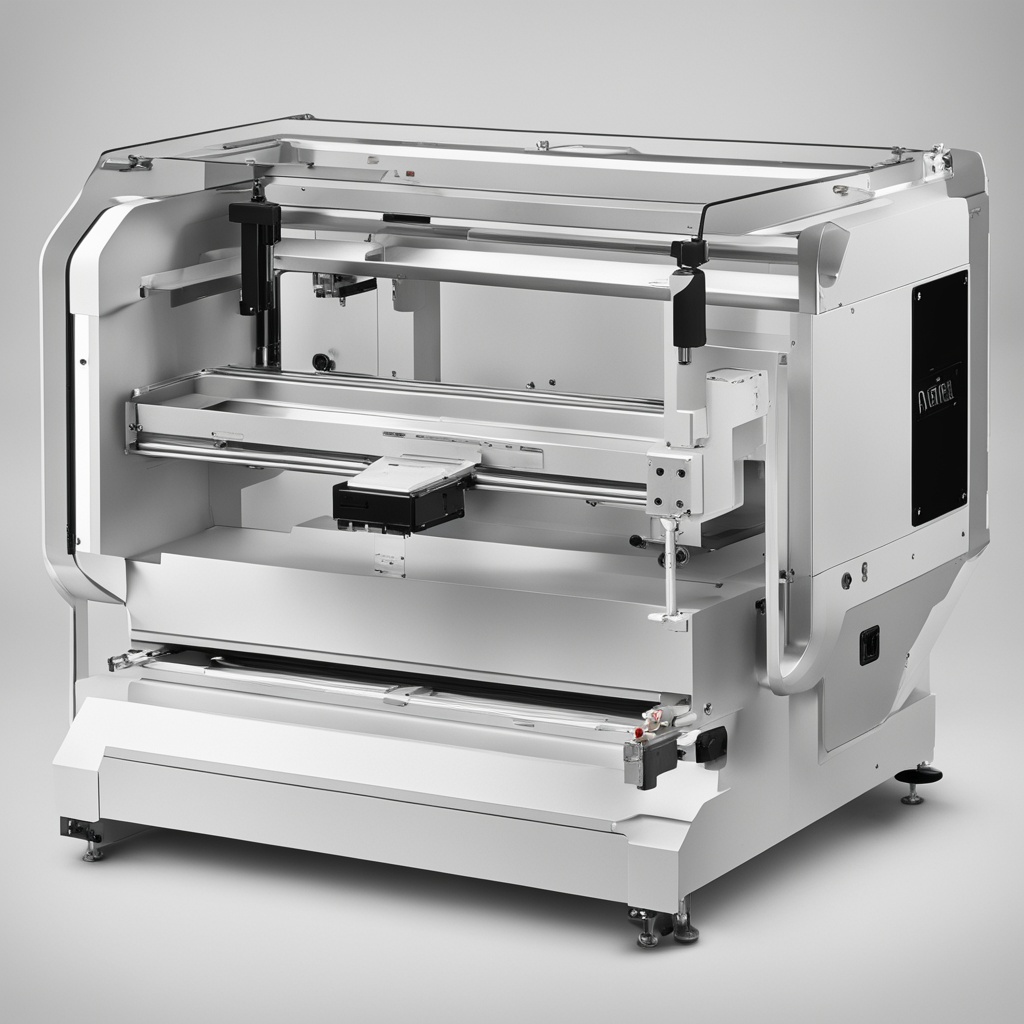

Selecting a metal laser engraving machine requires evaluating:

- Laser Power: 20W–100W for most metal applications.

- Work Area Size: Match to your largest typical workpiece.

- Software Compatibility: Supports industry-standard file formats.

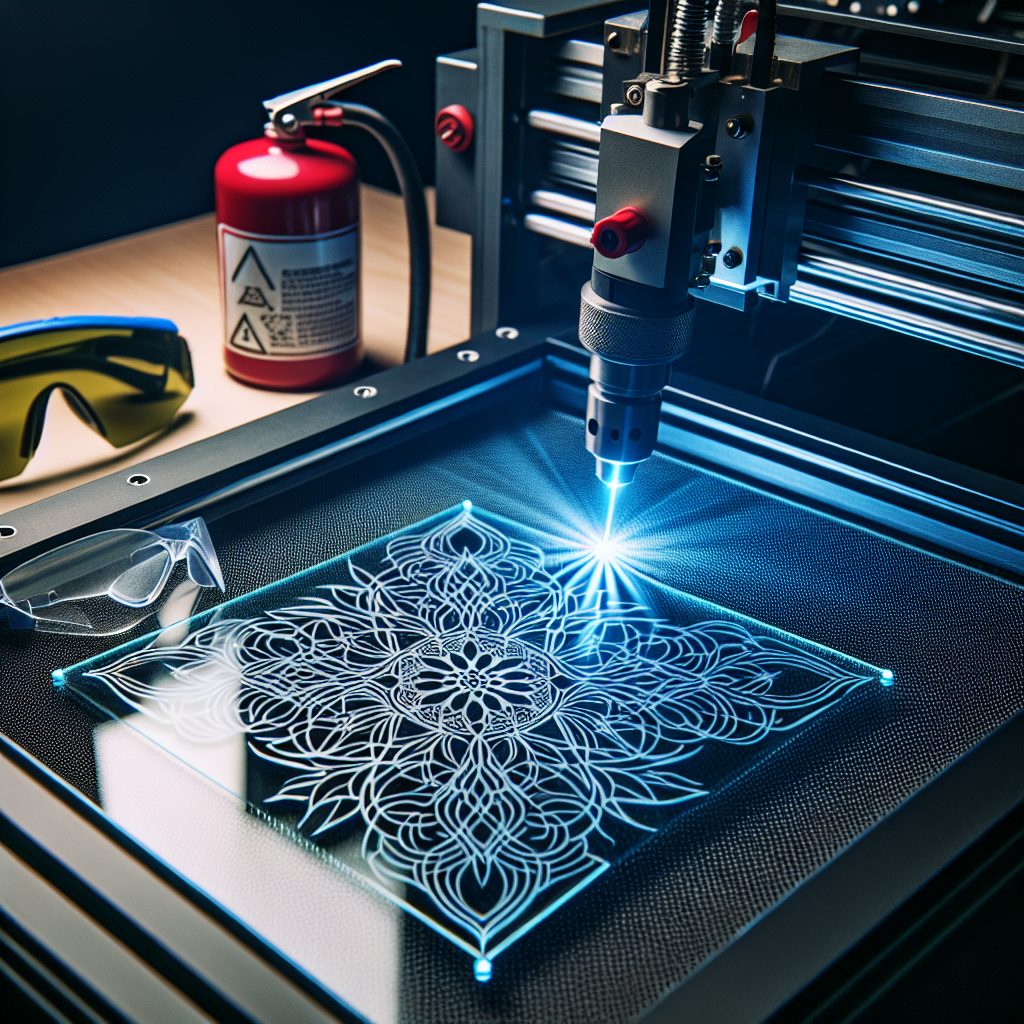

- Safety Features: Includes enclosures and emergency stops.

Critical question: Should you prioritize initial cost savings or long-term ROI through higher-speed, lower-maintenance systems?

Maintenance Best Practices for Peak Performance

To maximize the lifespan of your metal laser engraving machine:

- Clean optical lenses weekly with specialized solutions.

- Calibrate the focus lens after every 50 hours of operation.

- Monitor cooling system fluid levels and purity.

- Update firmware to access performance enhancements.

Pro Tip: Partner with manufacturers offering comprehensive training and support packages.

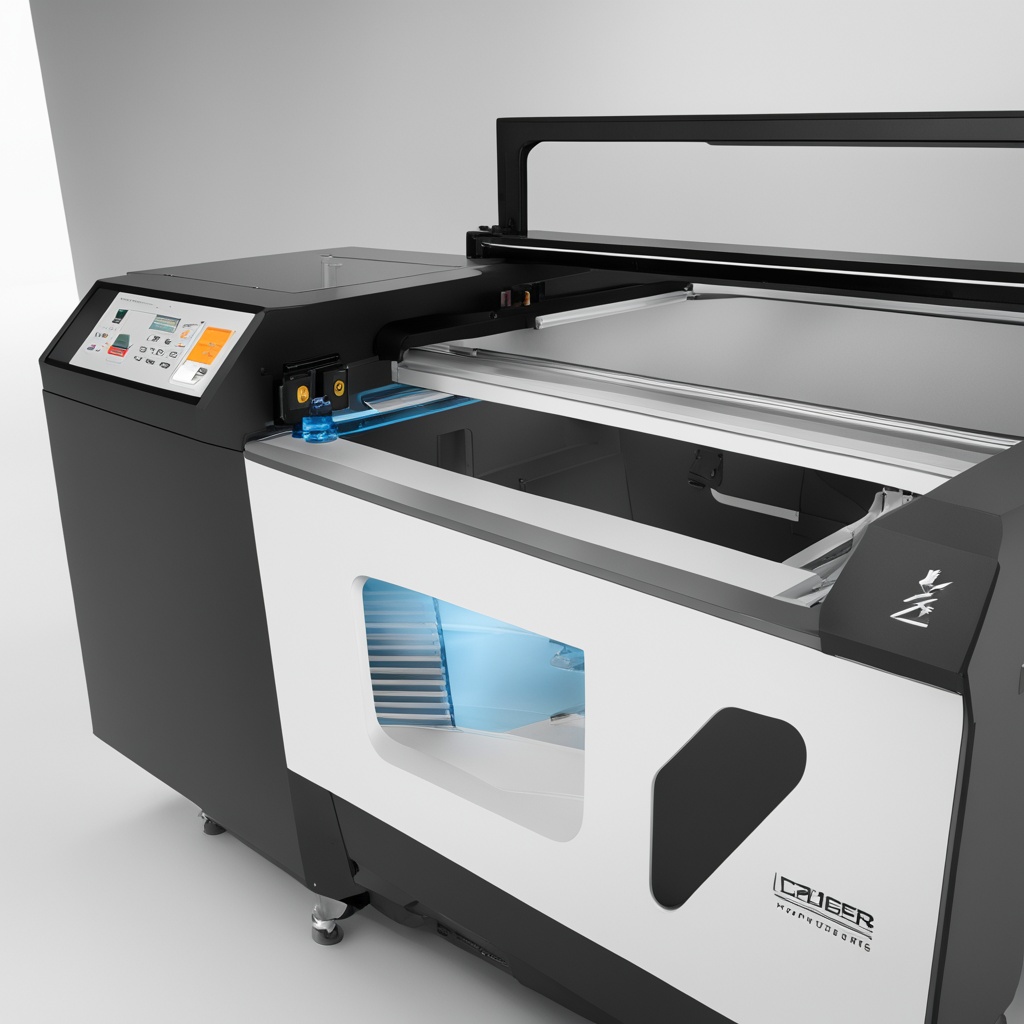

Future Trends in Metal Laser Engraving Technology

The next generation of metal laser engraving machine systems will likely incorporate:

- AI-driven predictive maintenance algorithms

- Hybrid additive/subtractive manufacturing capabilities

- Ultrafast femtosecond lasers for zero-heat-affected zones

- IoT integration for remote monitoring

Food for thought: How will these advancements reshape supply chains and product personalization?

Frequently Asked Questions

Q1: Can a metal laser engraving machine handle curved surfaces?

Yes, advanced models like the Hawk F1 feature rotary attachments for cylindrical objects such as cups and tubes.

Q2: What safety certifications should I look for?

Ensure compliance with ISO 11553 (laser safety) and CE/UL electrical standards.

Q3: How does laser wavelength affect metal engraving?

Fiber lasers (1064 nm) excel on metals, while CO2 lasers (10.6 μm) are better suited for non-metallics.

As industries continue to demand higher precision and customization, metal laser engraving machine technology stands poised to redefine manufacturing paradigms. By understanding their capabilities and strategic implementations, businesses can unlock new levels of productivity and creativity.