Laser Engraving Glass Power Settings: A Comprehensive Guide

Introduction

Laser engraving glass is an intricate and fascinating process that combines artistry with advanced technology. The precision and control offered by laser engraving machines make them ideal for creating intricate designs, logos, and patterns on glass surfaces. In this guide, we will delve into the specifics of laser engraving glass power settings, machine specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas. We will also explore some frequently asked questions about laser engraving machines.

Laser Engraving Technology and Applications

Laser engraving technology uses a high-intensity laser beam to create permanent marks or designs on various materials, including glass. The laser beam is focused onto the surface of the glass, causing localized heating that results in either the removal of material (engraving) or a change in the material’s surface properties (marking). This technology is widely used in various industries, such as jewelry, awards and trophies, architectural glass, and art.

- Jewelry: Engraving names, dates, or intricate designs on glass jewelry pieces adds a personal touch and enhances their aesthetic appeal.

- Awards and Trophies: Customized engravings on glass awards and trophies make them unique and memorable.

- Architectural Glass: Laser engraving can be used to create privacy glass, decorative patterns, and wayfinding signs in architectural applications.

- Art: Artists use laser engraving to create stunning glass art pieces, from simple designs to complex, multi-layered works.

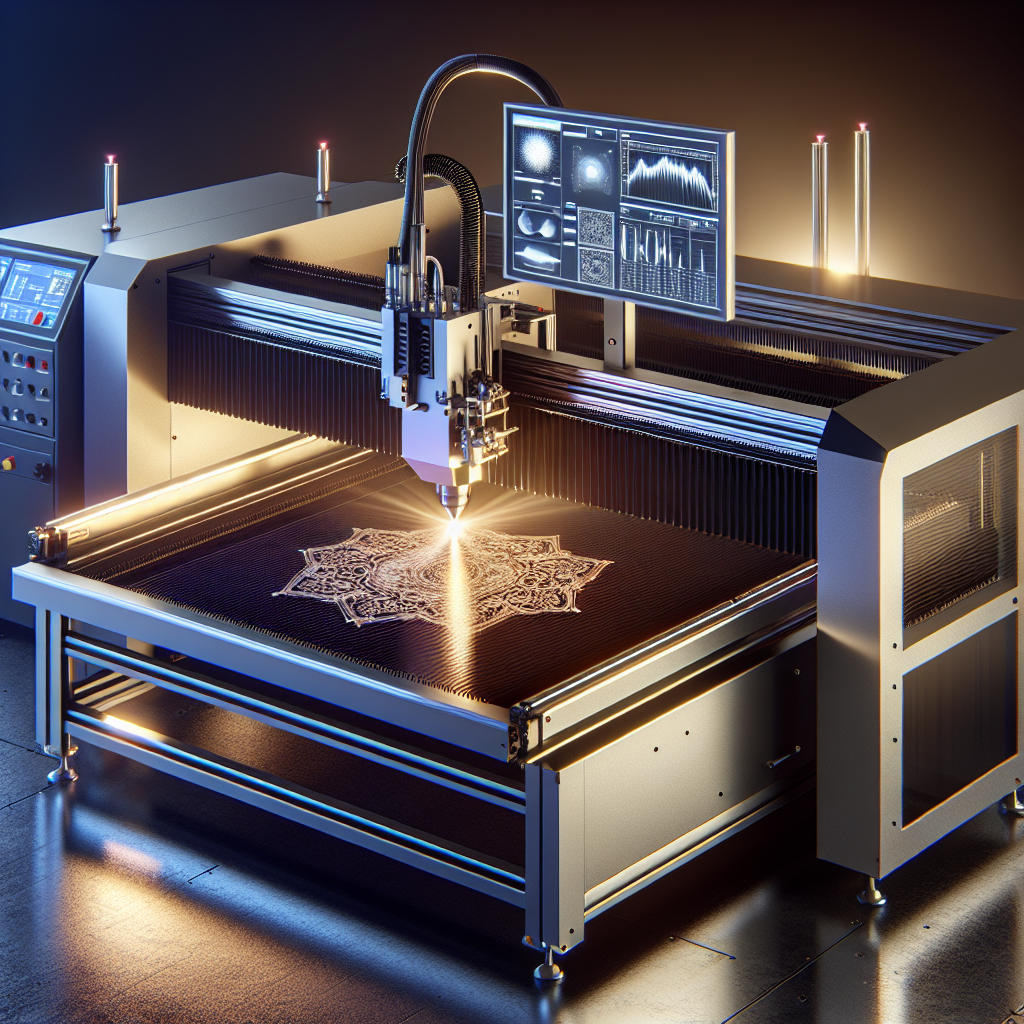

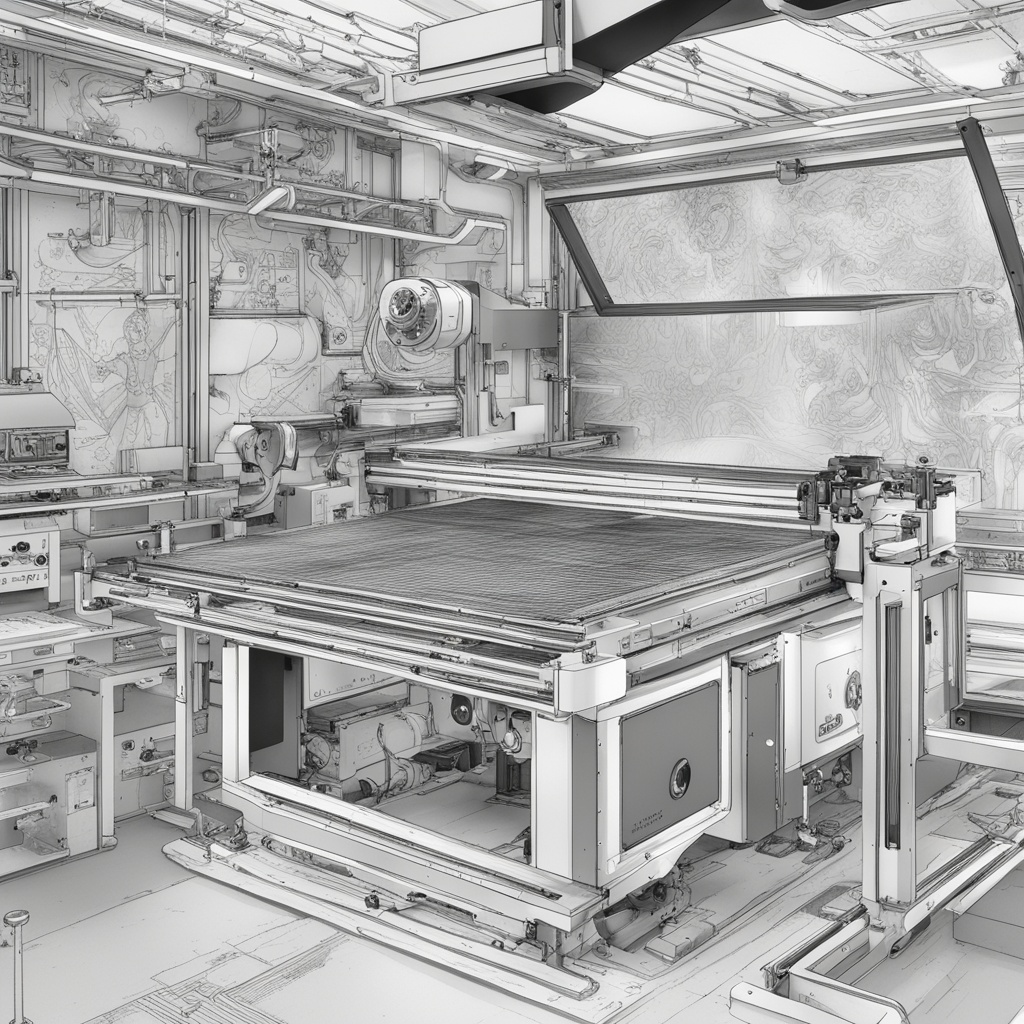

Machine Specifications and Features

When choosing a laser engraving machine for glass, it’s crucial to consider its specifications and features. Key factors include:

- Laser Power: The power of the laser beam determines the depth and speed of the engraving. For glass, a higher power laser is typically required to achieve clean and precise cuts.

- Beam Focus: The ability to adjust the beam focus allows for more control over the engraving process, enabling fine details and deeper cuts.

- Workspace Size: The workspace should accommodate the size of the glass pieces you plan to engrave.

- Software Compatibility: Ensure the machine is compatible with your design software for seamless workflow.

Our laser engraving glass power settings machine, the Hawk F1, is designed specifically for glass applications. It features a high-power laser, adjustable beam focus, and a large workspace, making it ideal for a range of glass engraving projects.

Material Compatibility

Laser engraving machines can work with various types of glass, including:

- Annealed Glass: This type of glass is the most common and is suitable for basic engraving.

- Tempered Glass: Engraving tempered glass is more challenging due to its strength and heat resistance, but it can be done with the right settings and equipment.

- Crystal Glass: Known for its clarity and brilliance, crystal glass is often engraved for luxury items and awards.

- Colored Glass: Engraving colored glass can yield striking results, with the laser revealing different shades and patterns beneath the surface.

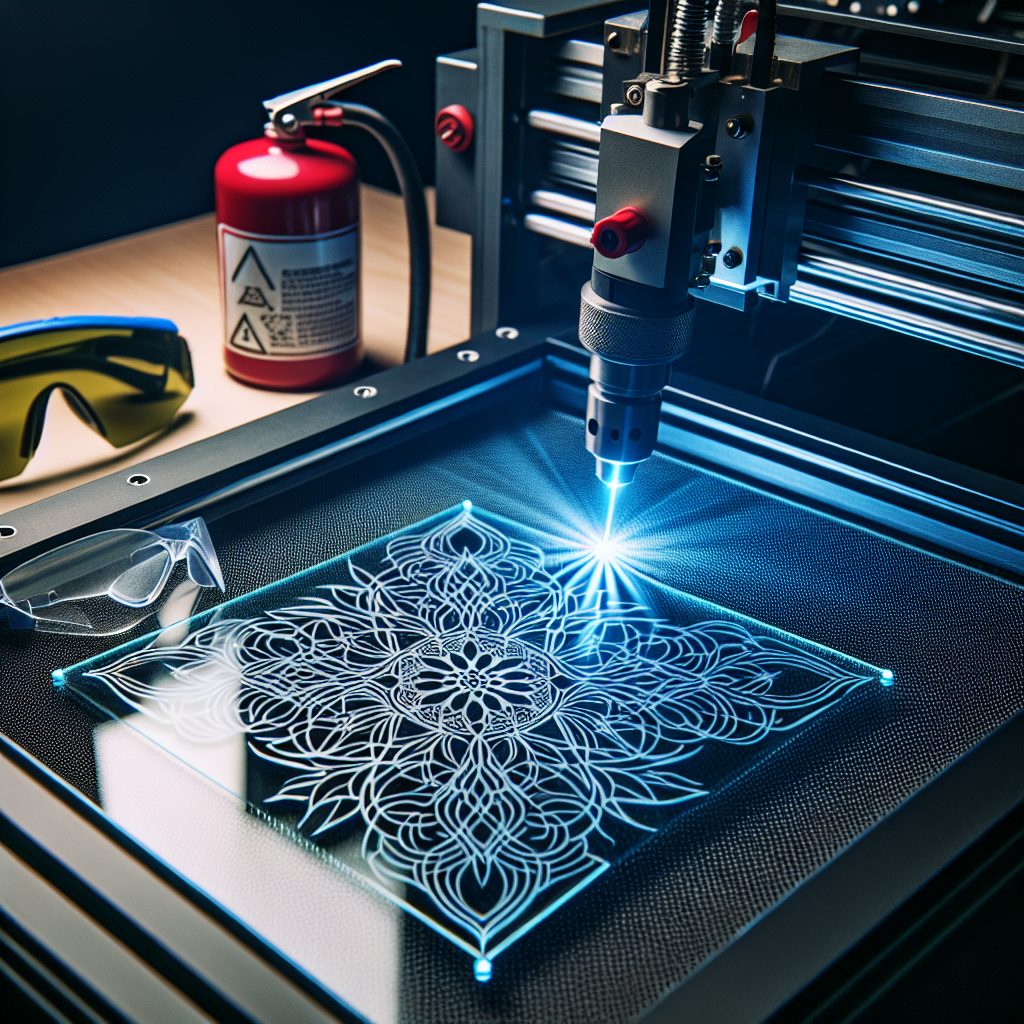

Safety Considerations

Safety is paramount when working with laser engraving machines. Here are some essential safety tips:

- Protective Eyewear: Always wear laser-safe glasses to protect your eyes from laser radiation.

- Ventilation: Ensure proper ventilation to prevent the accumulation of laser-generated fumes and particles.

- Fire Precautions: Keep a fire extinguisher nearby and have a clear evacuation plan in case of a fire.

- Training: Provide comprehensive training to all operators to ensure they understand the machine’s safety features and emergency procedures.

Industry Best Practices

To achieve optimal results and maximize the lifespan of your laser engraving machine, follow these industry best practices:

- Regular Maintenance: Clean the lens, mirrors, and other optical components regularly to maintain beam quality.

- Calibration: Periodically calibrate the machine to ensure accurate engravings.

- Material Testing: Always test your settings on a scrap piece of glass before starting a project.

- Software Optimization: Use the latest software updates to take advantage of new features and improvements.

Cost-Benefit Analysis

Investing in a laser engraving machine for glass can be a significant expenditure, but it offers numerous benefits:

- Efficiency: Laser engraving is faster and more precise than traditional methods, reducing labor costs and increasing productivity.

- Quality: The high-quality engravings produced by laser machines enhance the value of the final product.

- Scalability: As your business grows, you can expand the range of services offered with additional laser engraving capabilities.

Maintenance Tips

Proper maintenance is crucial for the long-term performance of your laser engraving machine. Here are some tips:

- Clean the Optics: Regularly clean the laser lens, mirrors, and nozzles to prevent dust and debris from affecting beam quality.

- Check Belts and Pulleys: Ensure belts and pulleys are tight and free of wear to maintain precision.

- Lubricate Moving Parts: Apply a suitable lubricant to moving parts to reduce friction and wear.

- Regular Inspection:

Conduct regular inspections of all components, looking for signs of wear or damage.

Project Ideas and Tutorials

Laser engraving glass opens up a world of creative possibilities. Here are some project ideas to inspire you:

- Customized Glassware: Engrave glasses, wine bottles, or vases with names, dates, or personal messages.

- Artistic Decor: Create unique wall art, tabletops, or decorative objects using intricate laser-engraved designs.

- Functional Objects: Engrave glass coasters, trivets, or other functional items with practical yet stylish designs.

- Memorial Pieces: Create personalized memorial plaques or keepsakes with laser-engraved images or text.

To get started, consider following these tutorials:

- Basic Glass Engraving: Learn the fundamentals of laser engraving glass, including setting up your machine, choosing the right power settings, and creating simple designs.

- Advanced Techniques: Explore advanced techniques such as gradient shading, multi-layered designs, and engraving on curved surfaces.

Frequently Asked Questions

Here are some common questions about laser engraving machines for glass:

- What is the best laser power for engraving glass? The best laser power depends on the type of glass and the desired depth of engraving. Generally, a higher power laser is required for glass due to its hardness and heat resistance.

- Can I engrave tempered glass? While more challenging, it is possible to engrave tempered glass with the right settings and equipment. It’s essential to test your settings on a scrap piece first.

- What safety precautions should I take when laser engraving glass? Always wear laser-safe glasses