Laser Engraving Software Free Laser Engraving Machines: An In-Depth Guide

Introduction to Laser Engraving Technology and Applications

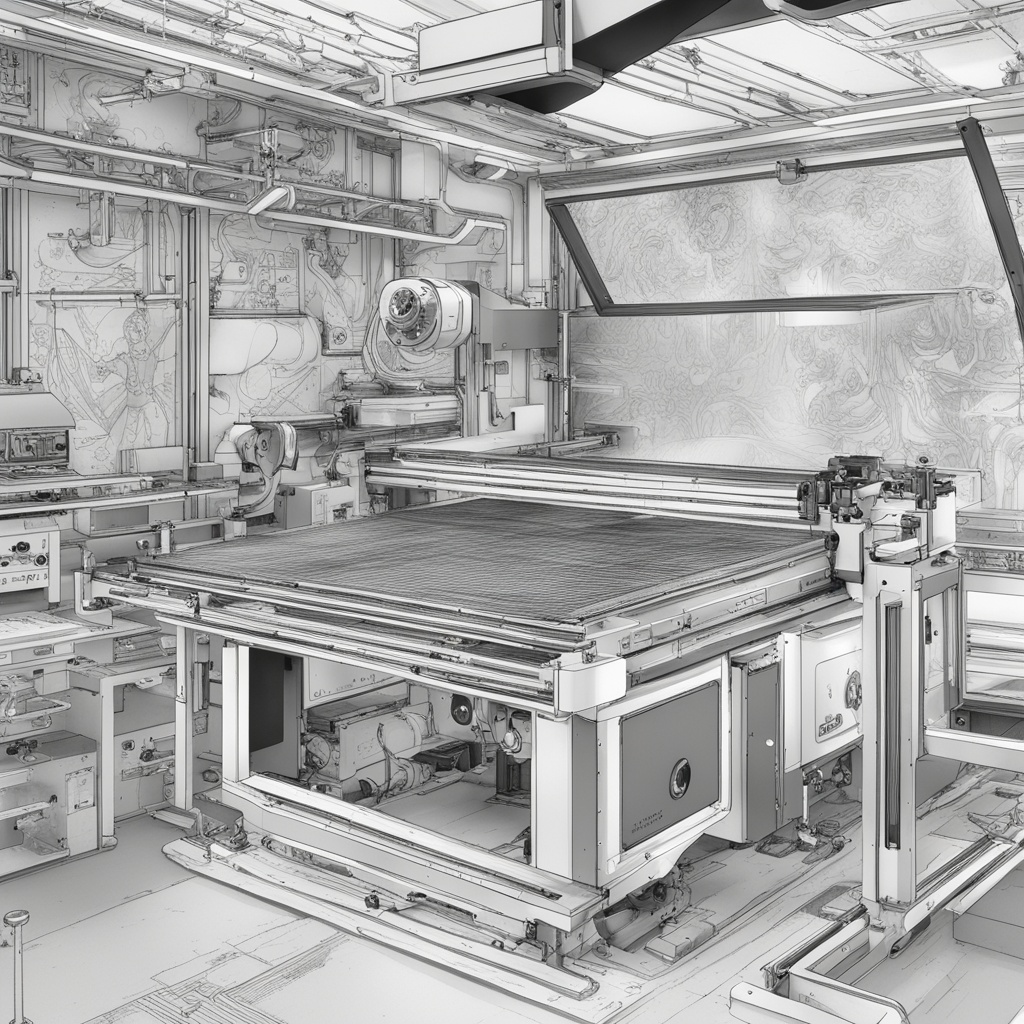

Laser engraving technology has revolutionized the way we create intricate designs, personalize items, and produce prototypes. This advanced method utilizes high-energy laser beams to precisely etch or cut materials, resulting in stunning detail and precision. From hobbyists to professionals, laser engraving machines have become indispensable tools across various industries.

Applications of laser engraving are vast and diverse. From personalizing jewelry and gifts to creating prototypes for product design, these machines offer endless possibilities. They are also used in education, signage, and even in the medical field for creating precise tools and devices. With the advent of laser engraving software free machines, accessibility to this technology has never been more widespread.

Machine Specifications and Features

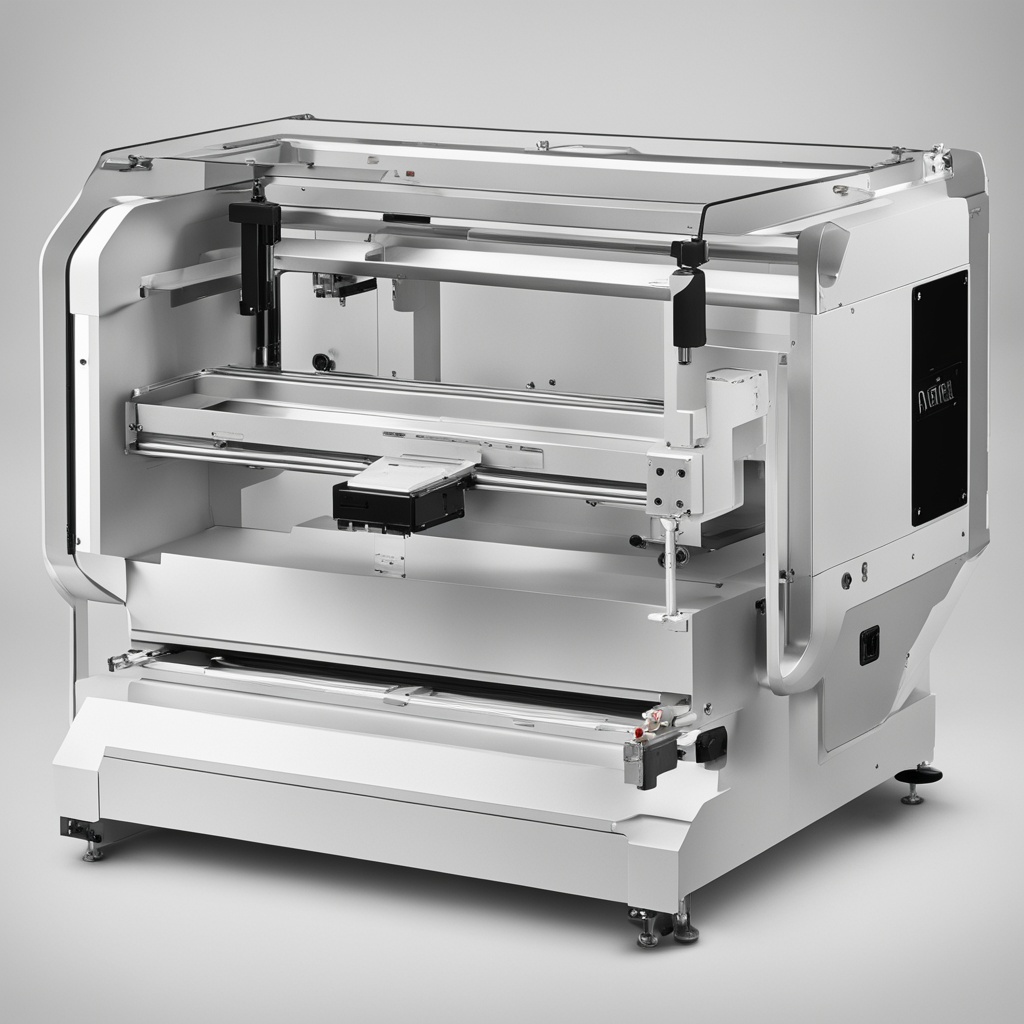

When choosing a laser engraving machine, it is crucial to consider its specifications and features. High-quality machines like the Hawk S1 offer a combination of power, precision, and user-friendliness. Here are some key specifications to look for:

- Laser Power: The power of the laser beam determines the depth and speed of engraving. Machines with adjustable laser power offer greater versatility for different materials and applications.

- Work Area: The size of the work area is essential, especially if you plan to engrave large items. The Hawk S1 features a generous work area, making it suitable for a range of projects.

- Resolution: Higher resolution results in finer details. Look for machines with high DPI (dots per inch) for superior engraving quality.

- Software Compatibility: Ensure the machine is compatible with your preferred design software. The Hawk S1 comes with free laser engraving software, making it easy to get started without additional costs.

Additional features to consider include USB connectivity, safety interlocks, and ventilation systems to prevent overheating. The Hawk S1 excels in these areas, providing a comprehensive package for both beginners and experienced users.

Material Compatibility

Laser engraving machines can work with a wide range of materials, each requiring different settings and considerations. Here are some common materials and tips for working with them:

- Wood: Easy to engrave and cut, wood offers a natural look and feel. Different types of wood react differently to laser engraving, so test settings on scraps before starting your project.

- Leather: Perfect for personalizing items like wallets and bags, leather can be easily engraved with clean, precise lines.

- Acrylic: Transparent or colored acrylic can create stunning effects. Be cautious of melting, as acrylic can release toxic fumes when lasered.

- Metal: Engraving metal requires higher power settings and may produce a marking rather than a deep cut. Coatings or treatments can enhance the engraving process.

Always refer to the machine’s manual for specific material guidelines and safety instructions.

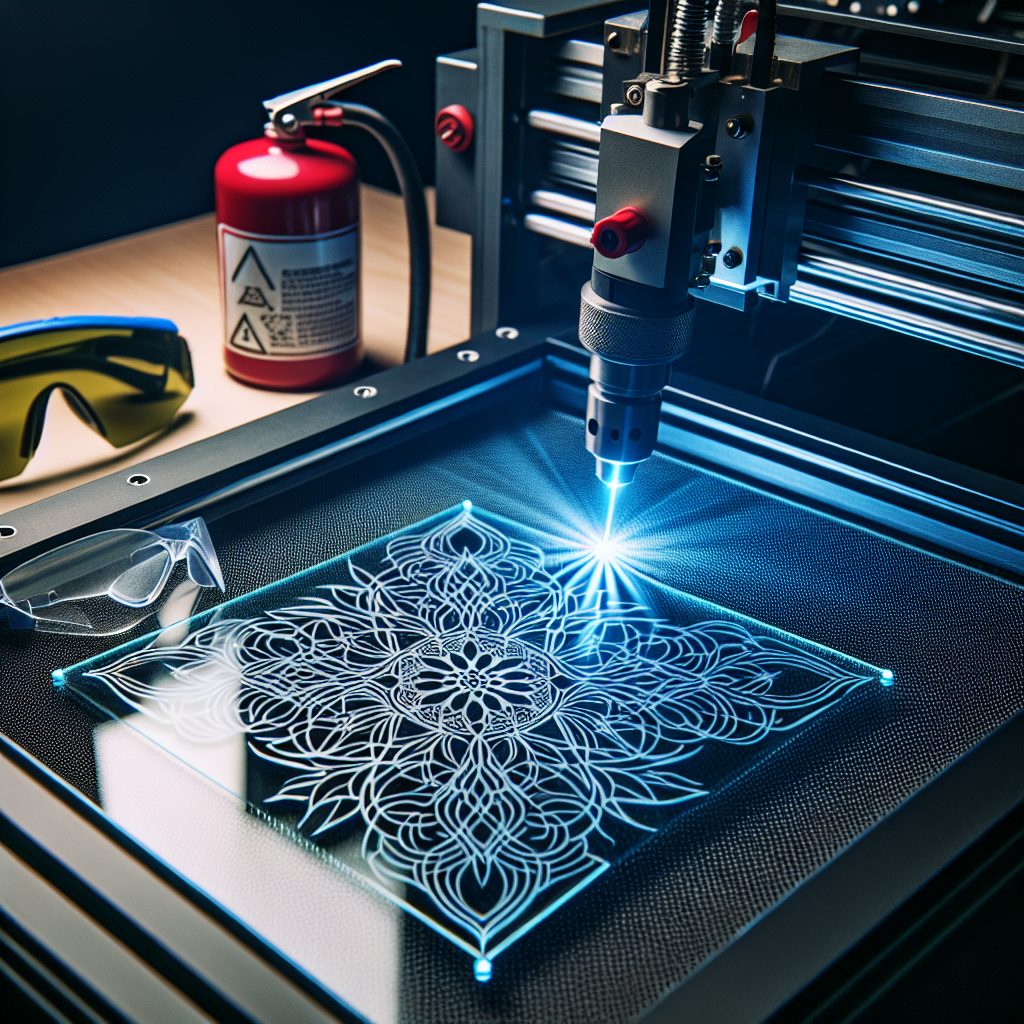

Safety Considerations

Laser engraving machines can be powerful tools, and safety should always be a top priority. Here are some essential safety tips:

- Eye Protection: Wear laser-safe goggles when operating the machine to protect your eyes from laser emissions.

- Ventilation: Ensure proper ventilation to prevent the accumulation of harmful fumes. Use a mask or respirator when working with materials like acrylic.

- Fire Precautions: Keep a fire extinguisher nearby and have a clear workspace to prevent accidental fires.

- Software Safety Features: Utilize software features like safety interlocks and emergency stops to halt the machine immediately if needed.

Regularly maintain your machine and inspect all components for wear and tear to minimize risks.

Industry Best Practices

To get the most out of your laser engraving machine and ensure high-quality results, follow these industry best practices:

- Calibrate Regularly: Regular calibration ensures accurate engravings and cuts. Follow the manufacturer’s instructions for calibration procedures.

- Use the Right Files: Ensure your design files are in the correct format and resolution. Vector files (like SVG or DXF) are ideal for laser cutting and engraving.

- Test Settings: Always test your settings on scrap material before starting your project. This helps prevent wasted materials and ensures perfect results.

- Clean Work Area: Keep your work area free of debris and obstacles to prevent accidents and ensure smooth operation.

Cost-Benefit Analysis

Investing in a laser engraving machine can be a significant financial decision. However, the benefits often outweigh the costs, particularly for businesses and professionals. Here’s a cost-benefit analysis to consider:

- Initial Investment: While the upfront cost can be high, quality machines like the Hawk S1 offer long-term durability and performance.

- Operational Costs: Ongoing costs, such as materials and maintenance, are relatively low. The free laser engraving software included with the Hawk S1 further reduces operational expenses.

- Time Savings: Laser engraving is much faster than traditional methods, allowing you to complete more projects in less time.

- Versatility: The ability to work with various materials and create intricate designs makes laser engraving machines highly versatile and profitable.

For businesses, the ability to offer personalized and customized products can set you apart from the competition, driving sales and customer satisfaction.

Maintenance Tips

Proper maintenance is crucial for the longevity and performance of your laser engraving machine. Here are some essential tips:

- Clean Lenses: Regularly clean the laser lens to prevent dust and debris from affecting beam quality.

- Lubricate Moving Parts: Use a suitable lubricant on moving parts to ensure smooth operation and reduce wear.

- Check Belts and Pulleys: Inspect belts and pulleys for wear and tightness, adjusting as necessary.

- Software Updates: Regularly update your software to benefit from new features and improvements.

A well-maintained machine will perform better, produce higher-quality results, and require fewer repairs over time.

Project Ideas and Tutorials

With a laser engraving machine, the possibilities for creative projects are endless. Here are some inspiring ideas and tutorials to get you started:

- Personalized Jewelry: Engrave names, dates, or initials on jewelry pieces for a personal touch. Start with simple designs and gradually move to more complex patterns.

- Custom Signage: Create unique signs for businesses or homes using wood, acrylic, or metal. Experiment with different fonts and layouts to find your style.

- Home Decor: Add a personal touch to home decor items like picture frames, coasters, and cutting boards. Engrave patterns, quotes, or family crests for a bespoke look.

- Educational Projects: Use laser engraving in educational settings to create prototypes, models, and educational aids. It’s a great way to bring learning to life and engage students.

For tutorials, many online resources offer step-by-step guides for various projects. The Hawk S1 community also provides valuable insights and tips from fellow users.

Questions to Consider When Buying a Laser Engraving Machine

Before investing in a laser engraving machine, consider these questions to ensure you make the right choice: