What is the Best Laser Engraver

Laser Engraving Technology and Applications

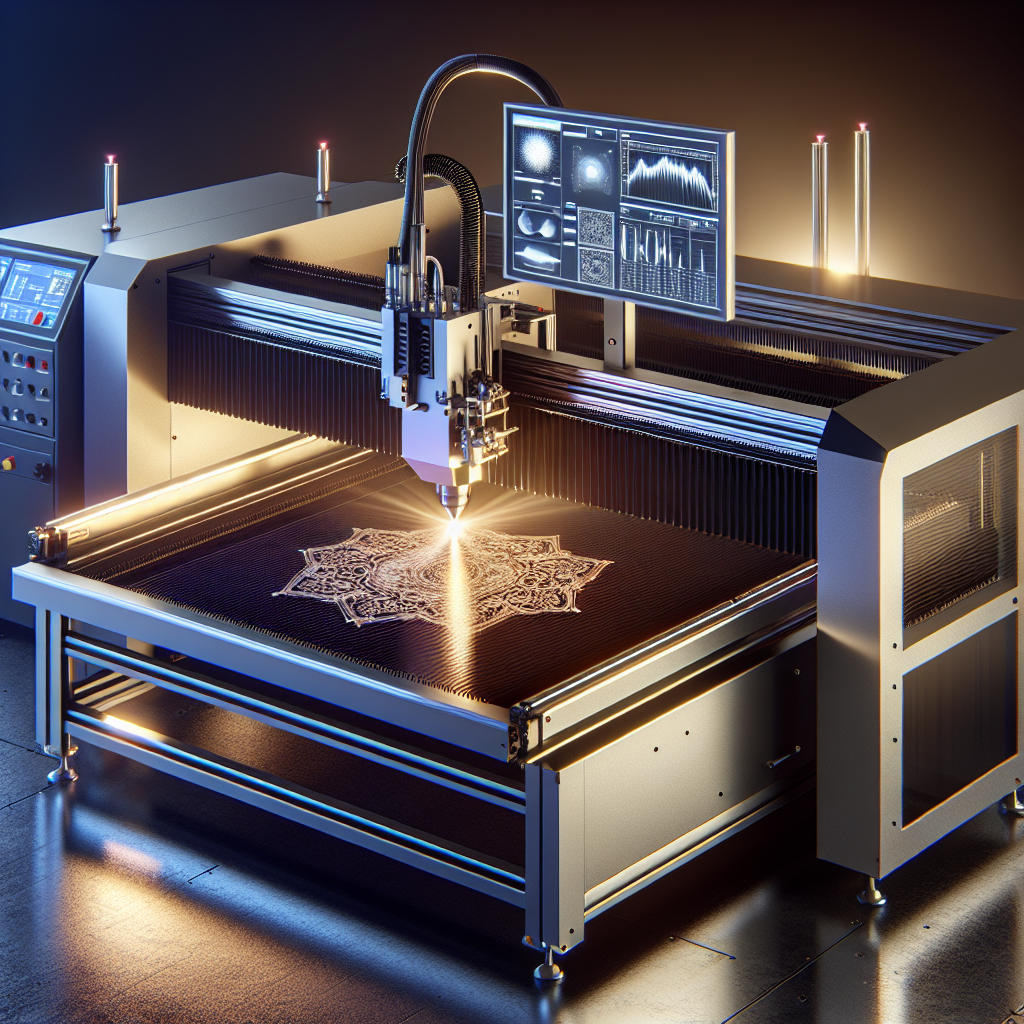

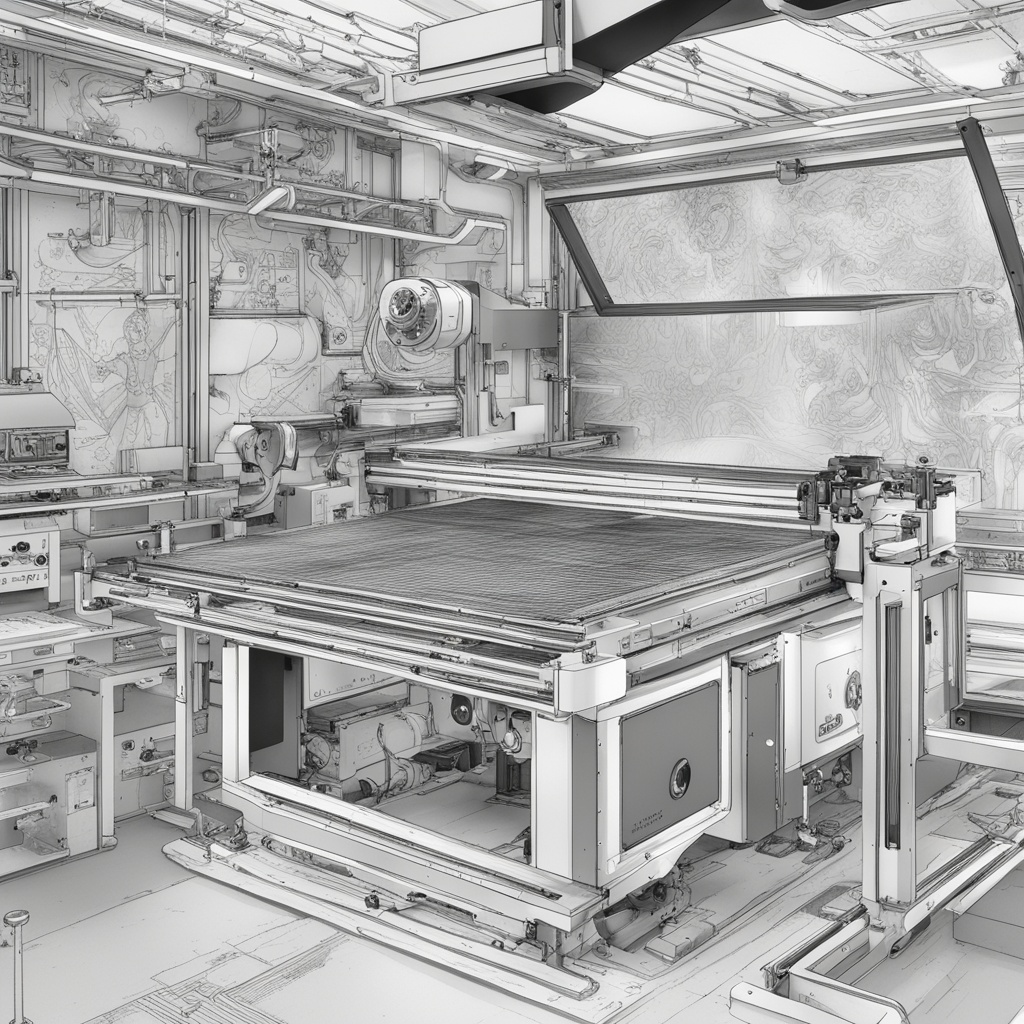

Laser engraving technology has revolutionized the way we create intricate designs and personalize items. This advanced process involves using a high-intensity laser beam to vaporize the surface material of an object, leaving a lasting impression that is both precise and detailed. From custom jewelry to personalized gifts, the applications of laser engraving are vast and ever-growing.

One of the most remarkable aspects of laser engraving is its versatility. The technology can be applied to a wide range of materials, including metals, plastics, woods, glass, and leather. This makes it an ideal choice for industries such as aerospace, automotive, medical, and jewelry manufacturing. Whether you need to mark serial numbers, logos, or intricate patterns, laser engraving offers unparalleled precision and consistency.

In the realm of personalization, laser engraving machines have become indispensable. They allow individuals and businesses to create unique and memorable items that stand out from the crowd. From engraved wedding rings to personalized phone cases, the creative possibilities are endless. Additionally, laser engraving is often used for security purposes, such as engraving serial numbers or barcodes onto products to prevent counterfeiting.

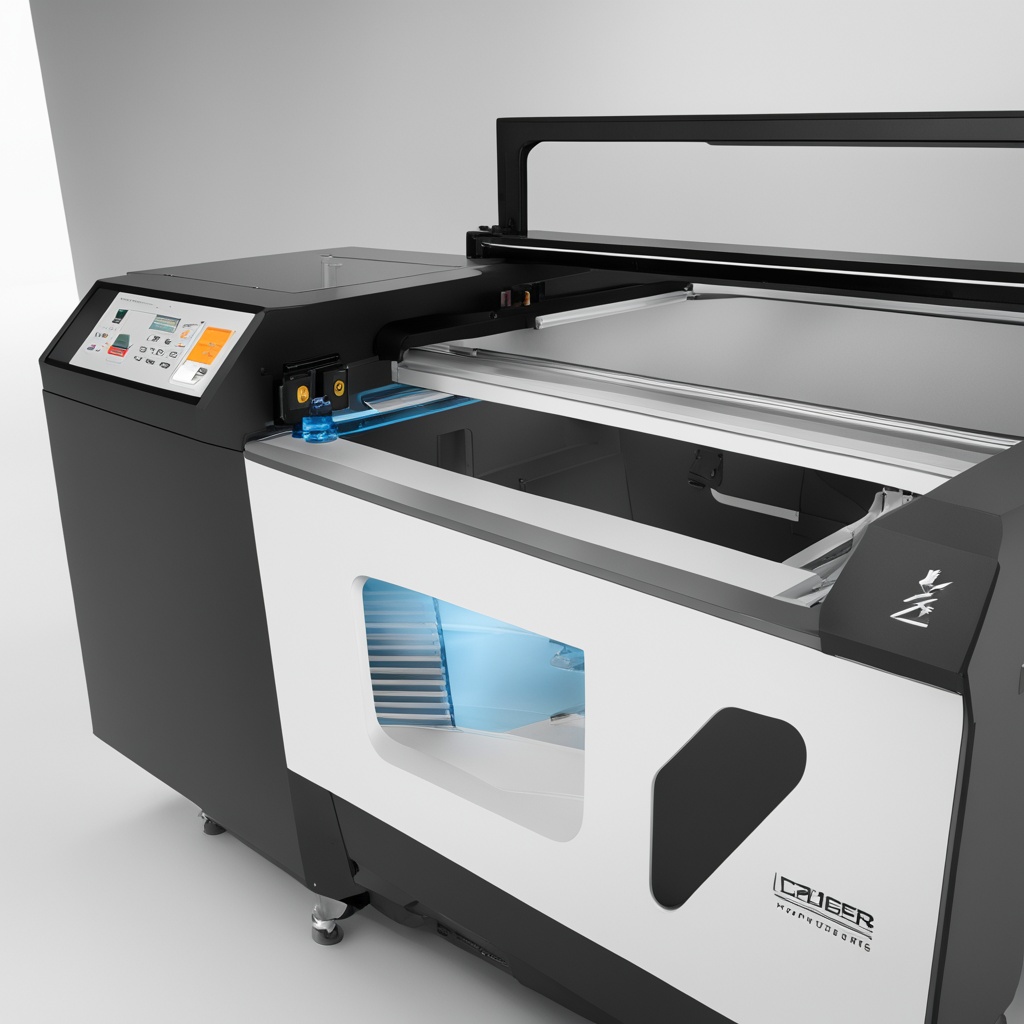

Machine Specifications and Features

When searching for what is the best laser engraver, it’s essential to consider the machine’s specifications and features. The best laser engravers on the market today offer a combination of power, precision, and ease of use. Here are some key factors to consider:

- Laser Power: The power of the laser beam determines the speed and depth of engraving. Higher power lasers can handle thicker materials and offer faster engraving speeds.

- Workspace Size: The workspace size refers to the area where the laser beam can move. Larger workspaces accommodate larger items, while smaller workspaces are more suitable for detailed, small-scale projects.

- Resolution: Resolution refers to the fineness of detail that the laser engraver can achieve. Higher resolution machines produce sharper, more intricate designs.

- Software Compatibility: The best laser engravers come with user-friendly software that allows for easy design and project setup. Compatibility with popular design software such as Adobe Illustrator and CorelDRAW is also a plus.

- Safety Features: Safety is paramount when working with laser engraving machines. Look for machines with built-in safety features, such as emergency stop buttons, interlocks, and laser safety glasses.

The LaserHawk LX1, for example, is a top-tier laser engraver that combines high power (60 watts) with a large workspace (20″ x 12″) and high resolution (1000 dpi). Its intuitive software and comprehensive safety features make it an excellent choice for both professionals and hobbyists.

Material Compatibility

Material compatibility is another critical factor to consider when choosing a laser engraver. Different materials respond differently to laser engraving, and some may require specific settings or preprocessing steps. Here are some common materials and their compatibility with laser engraving:

- Metals: Many metals can be laser engraved, but they often require a coating or pretreatment to achieve the desired results. Engraving metals typically involves removing a thin layer of material to reveal the underlying surface.

- Plastics: Plastics are highly compatible with laser engraving. The laser beam can cut through some plastics and etch intricate designs onto others. Acrylic, polycarbonate, and polyethylene are popular choices.

- Woods: Woods are excellent for laser engraving. The laser beam can create detailed patterns and text on a variety of wood types, from softwoods like pine to hardwoods like oak.

- Glass: Laser engraving glass involves creating a frosted or etched effect by focusing the laser beam on the surface. This process requires precision and specialized techniques to avoid cracking or breaking the glass.

- Leather: Leather is another popular material for laser engraving. The laser beam can easily cut and etch designs onto leather, making it ideal for personalized items such as wallets, belts, and purses.

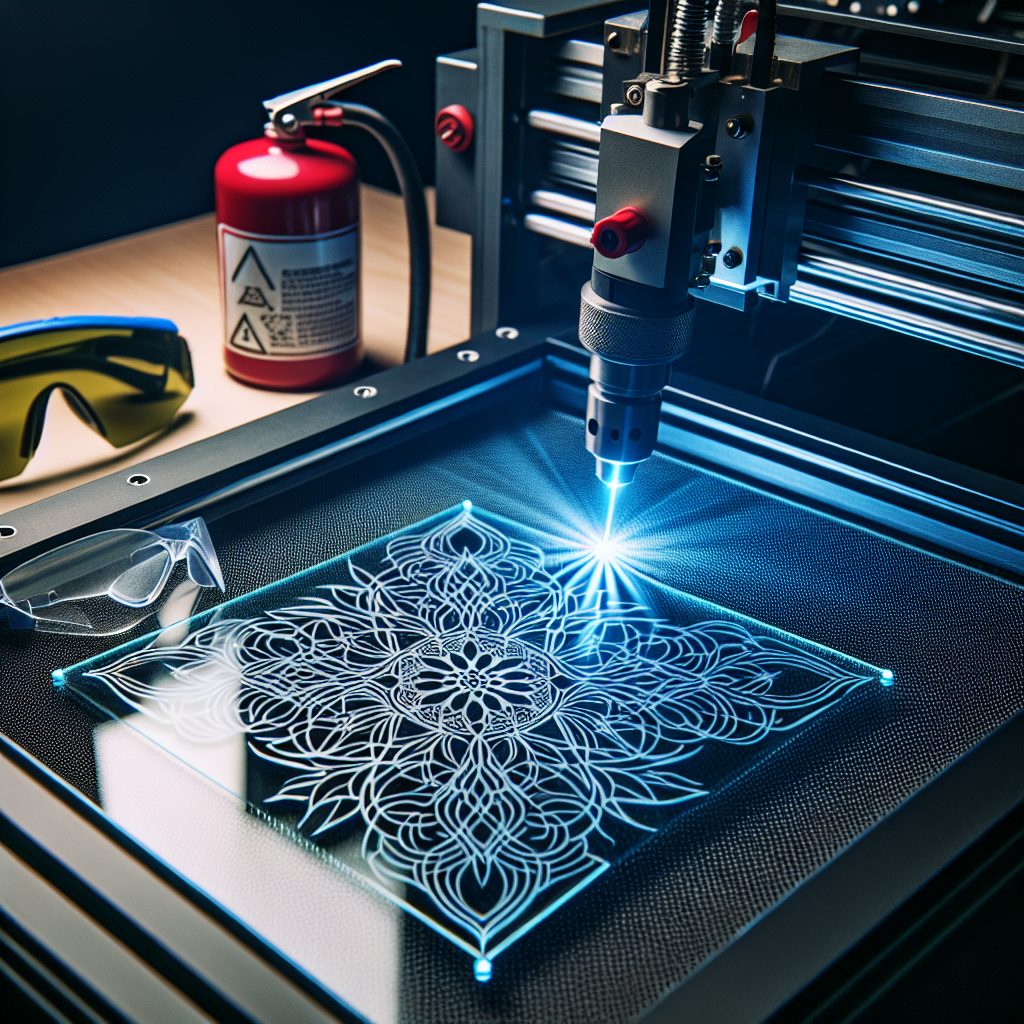

Safety Considerations

Safety is a critical aspect of laser engraving. The high-intensity laser beam can cause serious injury if not handled properly. Here are some essential safety considerations to keep in mind:

- Laser Safety Glasses: Always wear laser safety glasses when operating the laser engraver. These glasses protect your eyes from the intense laser light.

- Ventilation: Ensure proper ventilation in the workspace to prevent the buildup of harmful fumes and particles. Consider using a fume extractor or exhaust fan.

- Fire Prevention: Keep flammable materials away from the laser engraver and have a fire extinguisher nearby in case of an emergency.

- Training: Ensure that all operators are properly trained in the safe use of the laser engraver. This includes understanding the machine’s controls, emergency stop procedures, and material handling.

- Regular Maintenance: Regular maintenance of the laser engraver helps prevent accidents and ensures optimal performance. Check the machine regularly for any signs of wear or damage.

Industry Best Practices

To get the most out of your laser engraver, it’s essential to follow industry best practices. Here are some tips to help you achieve high-quality results and extend the lifespan of your machine:

- Use High-Quality Materials: Choosing high-quality materials ensures that your engraved designs will look their best and last longer.

- Optimize Settings: Experiment with different laser settings (power, speed, and frequency) to find the optimal combination for your specific material and design.

- Clean the Lens: Keep the laser lens clean and free of dust and debris. A dirty lens can cause the laser beam to scatter, reducing the quality of your engravings.

- Regular Calibration: Regularly calibrate your laser engraver to ensure that it is operating within specifications. This helps maintain precision and consistency.

- Backup Your Work: Regularly back up your designs and projects to prevent data loss. Consider using cloud storage or an external hard drive.

Cost-Benefit Analysis

When considering the purchase of a laser engraver, it’s essential to perform a cost-benefit analysis. While laser engravers can be a significant investment, they offer numerous benefits that can outweigh the initial cost. Here are some factors to consider:

- Versatility: Laser engravers can be used for a wide range of applications, making them a versatile addition to any workshop or business.

- Precision: The high precision of laser engraving allows for intricate designs and detailed personalization, enhancing the value of your products.

- Efficiency: Laser engravers offer faster processing times compared to traditional methods, allowing you to produce more items in less time.

- Scalability: As your business grows, laser engravers can scale with your needs. You can upgrade to more powerful machines or expand your workspace to accommodate larger projects.

- Return on Investment: By offering unique and personalized products, laser engraving can increase customer satisfaction and drive sales, leading to a quick return on investment.

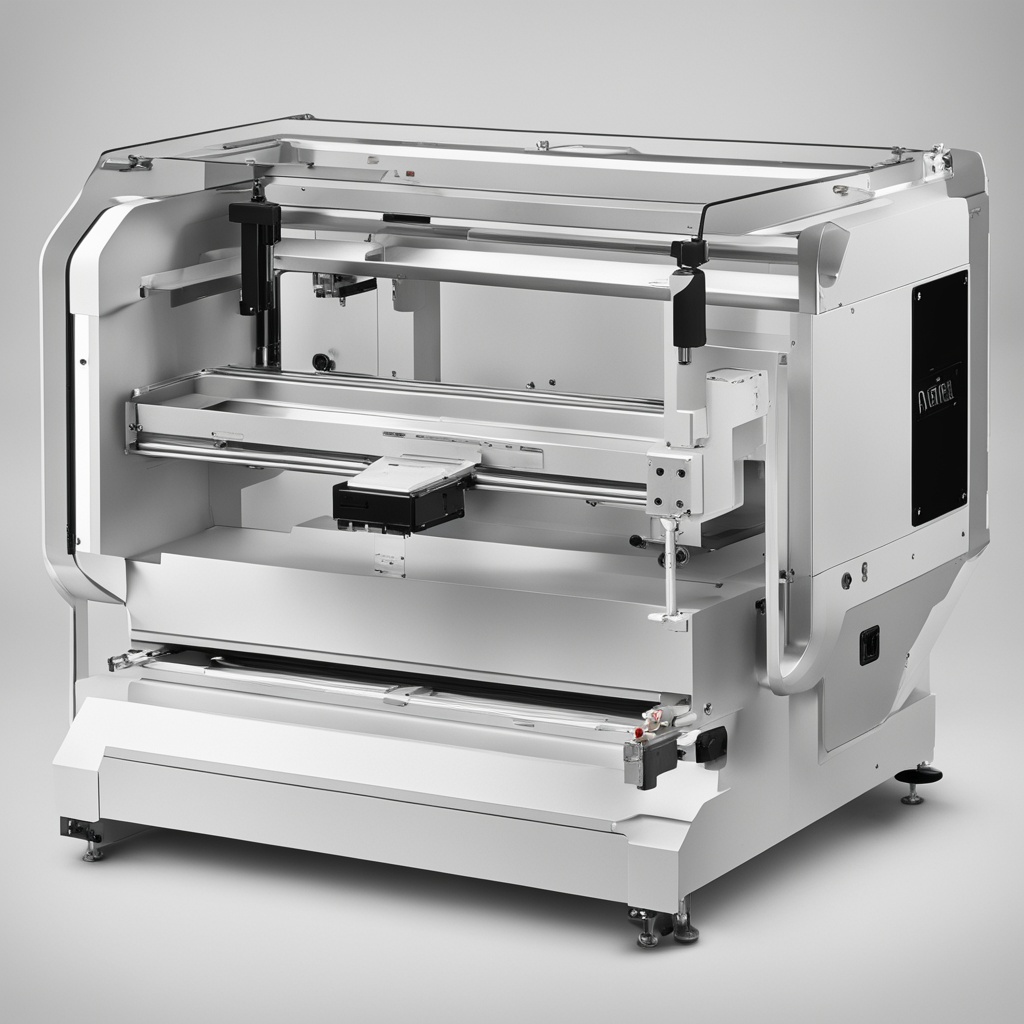

Maintenance Tips

Proper maintenance is essential for keeping your laser engraver in top condition. Here are some tips to help you maintain your machine:

- Clean Regularly: Regularly clean the machine’s internal and external components to remove dust and debris. Use compressed air or a vacuum cleaner for delicate areas.

- Inspect Lenses: Inspect the laser lens regularly for any signs of damage or contamination. Replace or clean the lens as needed.

- Lubricate Moving Parts: Apply a suitable lubricant to moving parts to reduce friction and wear. Follow the manufacturer