Laser Engraved Hats and the Magic of Laser Engraving Machines

Introduction to Laser Engraving Technology

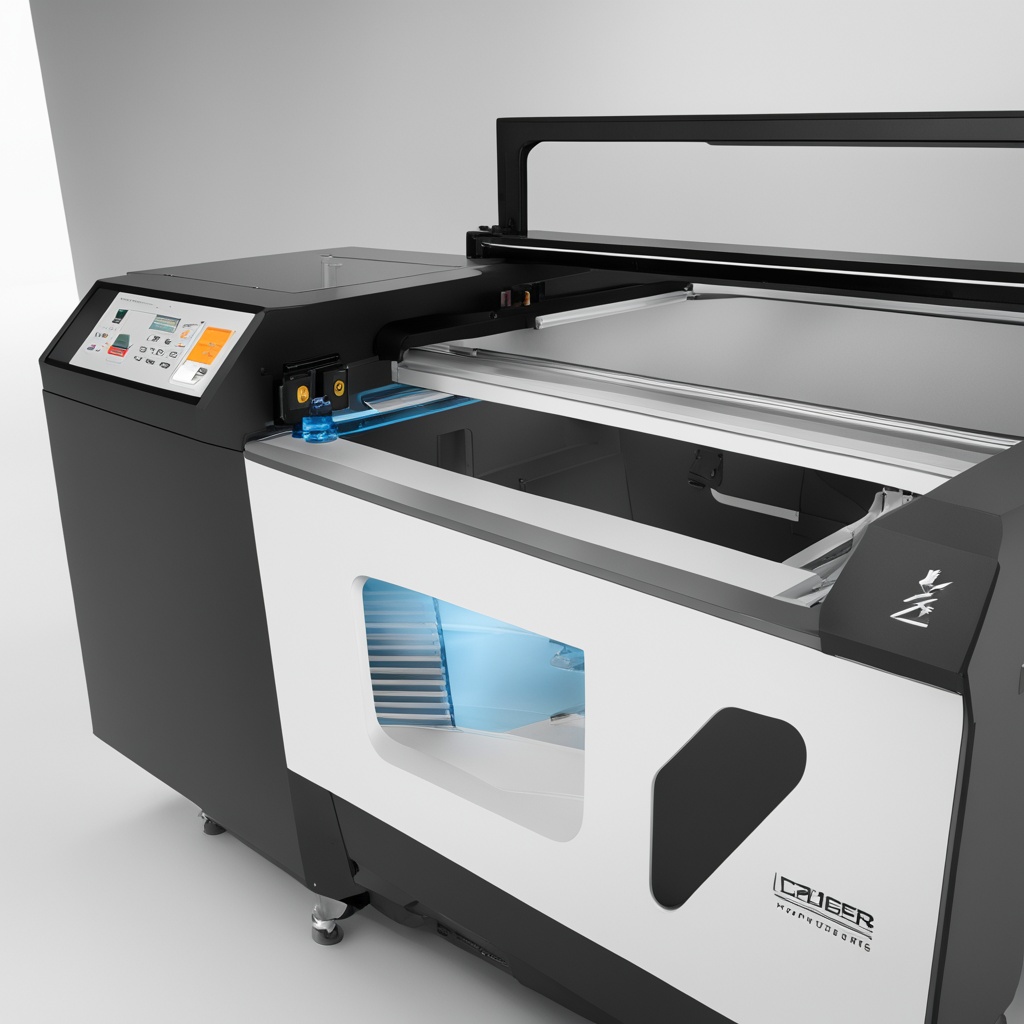

Laser engraving technology has revolutionized the customization and personalization of various products, including hats. This sophisticated method uses high-energy laser beams to create intricate designs, logos, and text on a wide range of materials. By focusing the laser beam on the surface of the material, it vaporizes a thin layer, revealing the desired pattern or text beneath. The precision and detail achievable with laser engraving machines make them an indispensable tool for artists, designers, and businesses alike.

Applications of Laser Engraving Machines in Hat Customization

One of the most exciting applications of laser engraving machines is in the customization of hats. From baseball caps to beanies, these machines can transform plain headwear into unique, stylish accessories. The versatility of laser engraving allows for a myriad of design possibilities, from simple text and logos to complex artwork and patterns. This technology offers a high level of customization that appeals to consumers looking for personalized items and brands seeking to enhance their brand recognition.

Businesses in the fashion and promotional industries have embraced laser engraving machines for hat customization. They can quickly and easily produce limited-edition designs, personalized gifts, and promotional items tailored to specific events or campaigns. The ability to offer such a high level of personalization has been a game-changer, setting these businesses apart from their competitors.

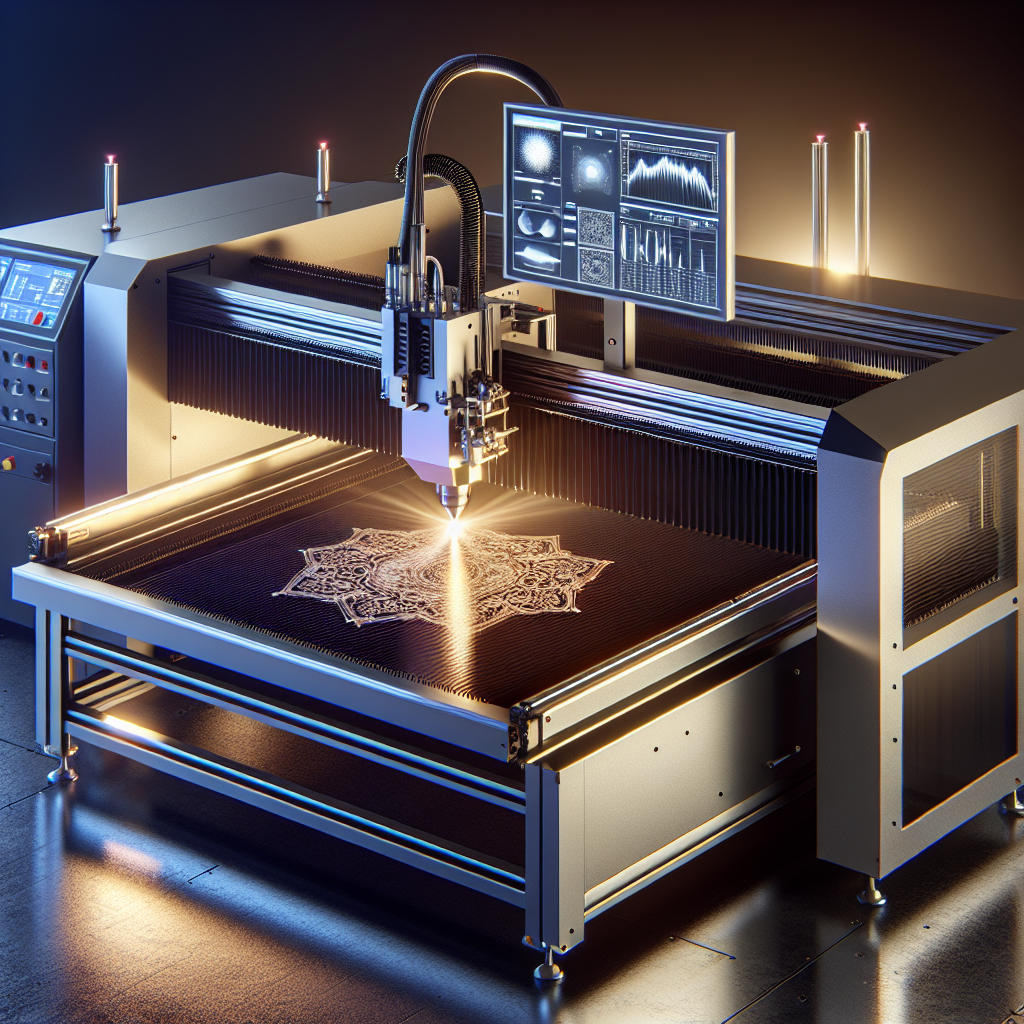

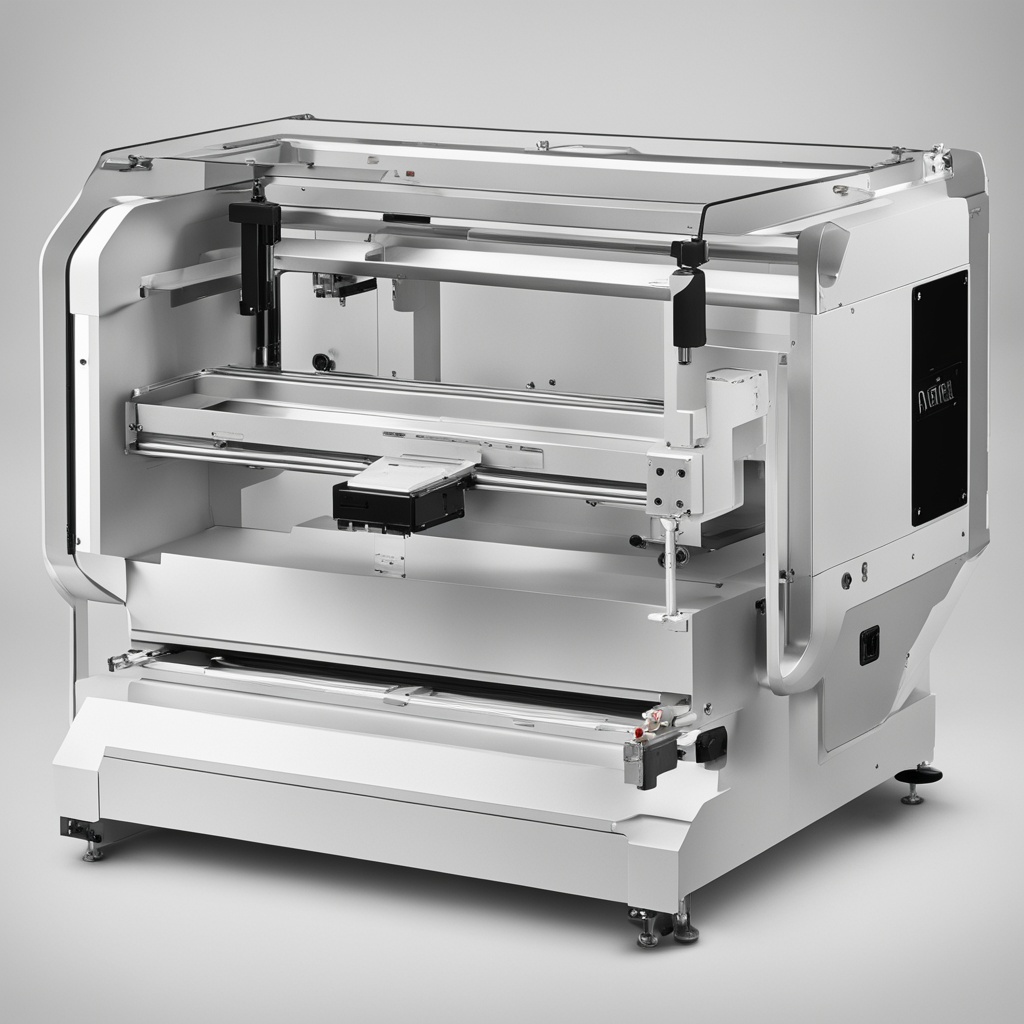

Machine Specifications and Features

When choosing a laser engraving machine for hat customization, it is crucial to consider the machine’s specifications and features. Here are some key factors to look for:

- Laser Power: The power of the laser beam determines the speed and depth of engraving. Higher power lasers can handle thicker materials and create deeper engravings.

- Engraving Area: The size of the engraving area should accommodate the hats you plan to customize. Machines with larger engraving beds can handle a wider range of hat sizes and shapes.

- Resolution: Higher resolution allows for finer details and sharper images. Look for machines with a resolution of at least 300 dpi for high-quality results.

- Software Compatibility: User-friendly software is essential for easy design creation and machine operation. Look for machines that come with intuitive software or are compatible with popular design programs.

- Material Compatibility: Ensure the machine can handle the materials you plan to use, such as cotton, polyester, and leather.

Top-of-the-line laser engraving machines, such as those available at laser engraved hats specialists, offer advanced features like autofocus, automatic material recognition, and wireless connectivity. These features enhance the machine’s versatility and ease of use, making it an excellent investment for businesses and professionals.

Material Compatibility

Laser engraving machines can work with a wide variety of materials, making them versatile for different applications. When it comes to hat customization, the most common materials include cotton, polyester, nylon, and leather. Each material has its unique properties and reacts differently to the laser beam.

Cotton and polyester hats are popular choices for laser engraving due to their affordability and durability. These materials can achieve a clean, crisp engraving with well-defined edges. Nylon hats are also suitable for laser engraving but may require a slightly different approach due to their stretchy nature. Leather hats offer a premium look and feel but require careful handling to avoid scorching or burning.

Understanding the material’s properties and adjusting the laser settings accordingly is crucial for achieving the best results. This may involve experimenting with different power levels, speeds, and frequencies to find the optimal settings for each material.

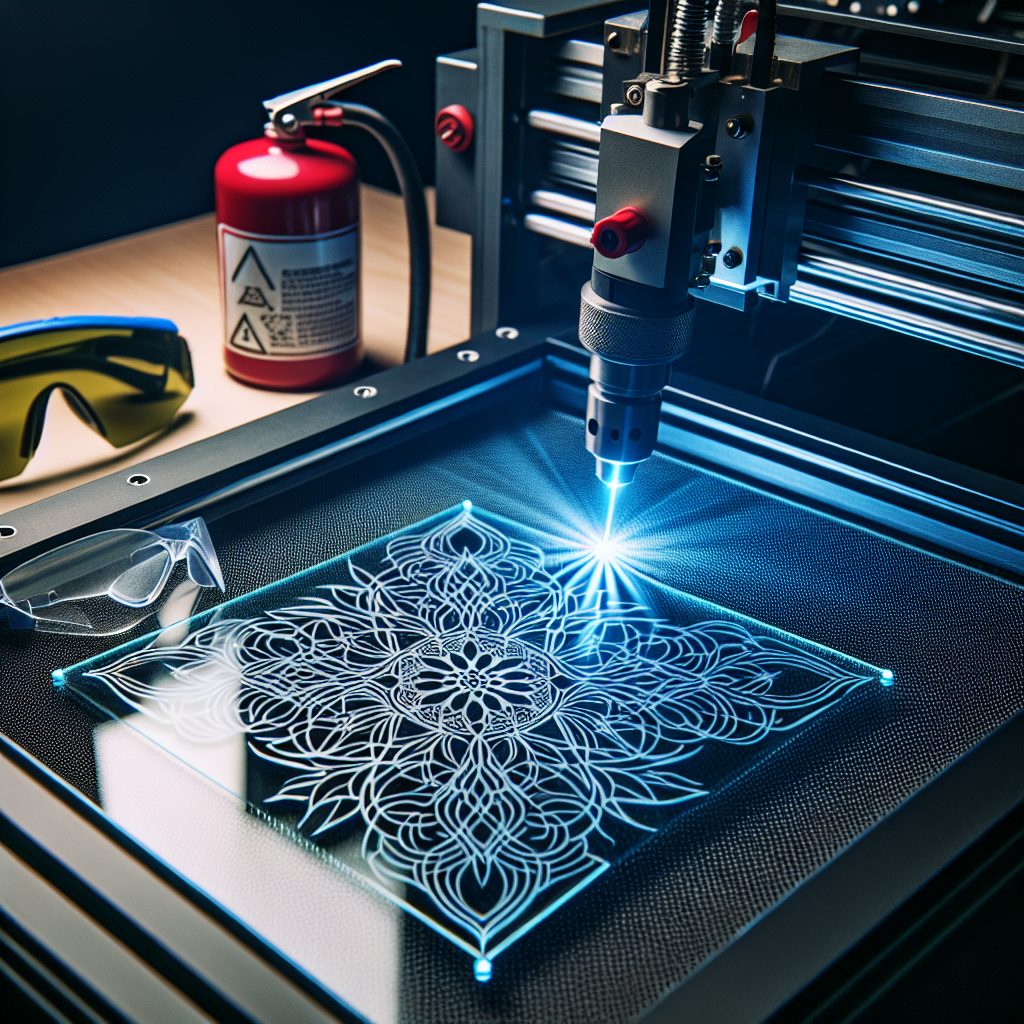

Safety Considerations

Safety is paramount when working with laser engraving machines. These high-energy devices can pose serious risks if not handled properly. Here are some essential safety tips:

- Personal Protective Equipment (PPE): Always wear laser safety goggles to protect your eyes from laser radiation. Additional PPE, such as gloves and masks, may be necessary depending on the material and process.

- Ventilation: Ensure adequate ventilation to prevent the buildup of harmful fumes and particles generated during the engraving process.

- Fire Precautions: Keep a fire extinguisher handy and have a clear escape route in case of a fire.

- Machine Enclosures: Use machine enclosures to contain the laser beam and minimize the risk of accidental exposure.

- Training: Provide comprehensive training to all operators to ensure they understand the machine’s safety features and emergency procedures.

Industry Best Practices

To get the most out of your laser engraving machine and ensure high-quality results, follow these industry best practices:

- Regular Maintenance: Perform regular maintenance checks, such as cleaning the lens, aligning the beam, and checking for worn parts. This ensures optimal machine performance and extends its lifespan.

- Calibration: Regularly calibrate the machine to ensure accurate engraving. This involves adjusting the laser beam’s focus and alignment to match the material and design requirements.

- Quality Control: Implement a quality control process to inspect each engraved hat for defects or imperfections. This ensures consistent quality and customer satisfaction.

- Software Updates: Keep the machine’s software up to date to benefit from the latest features and improvements. Regular updates can also address any known issues or bugs.

- Material Testing: Test different materials and settings to find the optimal combination for each project. This ensures the best possible results and minimizes waste.

Cost-Benefit Analysis

Investing in a laser engraving machine for hat customization can be a significant financial commitment. However, the benefits far outweigh the costs, especially for businesses looking to enhance their offerings and stand out in a competitive market.

In terms of cost savings, laser engraving machines can reduce labor costs associated with traditional engraving methods, such as hand carving or screen printing. They also offer a higher level of customization and precision, which can increase the perceived value of the product and justify a higher price point.

Additionally, laser engraving machines can increase production capacity, allowing businesses to take on more orders and scale their operations. The ability to quickly and easily produce personalized items also opens up new revenue streams, such as custom orders and limited-edition designs.

Maintenance Tips

Proper maintenance is crucial for keeping your laser engraving machine in top condition. Here are some essential tips:

- Clean the Lens: Regularly clean the laser lens to remove dust, debris, and residue that can affect the beam’s quality and focus.

- Check for Wear and Tear: Inspect all machine parts for signs of wear and tear, such as cracked mirrors, worn belts, or loose connections. Replace worn parts promptly to avoid downtime and ensure optimal performance.

- Lubricate Moving Parts: Use a suitable lubricant on moving parts, such as guides and bearings, to reduce friction and wear.

- Regular Calibration: Perform regular calibration checks to ensure the laser beam is correctly aligned and focused.

- Software Updates: Keep the machine’s software up to date to benefit from the latest features and improvements, and to address any known issues or bugs.

Project Ideas and Tutorials

Laser engraved hats are a blank canvas for creativity. Here are some project ideas and tutorials to inspire your next endeavor:

- Monogrammed Hats: Create personalized monograms on baseball caps or beanies using a combination of letters and symbols. This is a popular choice for gifts and promotional items.

- Company Logos: Engrave company logos on hats to promote brand recognition. This is an excellent way to create uniformity and build brand loyalty among employees and customers.

- Artistic Designs: Experiment with complex artwork and patterns to create unique, one-of-a-kind hats. This can be a great way to showcase your artistic talent and attract attention.

- Themed Hats: Create hats themed around specific events, sports teams, or hobbies. This can be a fun way to celebrate and show support for your favorite causes and activities.