Yeti Laser Engraving Machines: Unlocking Creativity and Precision

Laser engraving technology has revolutionized the way we personalize and decorate a wide range of materials. Among the leading names in this field is yeti laser engraving, known for its high-performance machines that blend precision, versatility, and ease of use. This article delves into the intricacies of yeti laser engraving machines, exploring their technology, applications, specifications, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and inspiring project ideas.

Laser Engraving Technology and Applications

Laser engraving involves using a high-intensity laser beam to create intricate designs, text, or images on various surfaces. This non-contact process allows for extreme precision and detail, making it ideal for a multitude of applications. From personalized gifts and jewelry to industrial prototyping and branding, the versatility of yeti laser engraving machines knows no bounds.

Personalization: One of the most popular applications is personalizing items such as phone cases, leather wallets, and wooden boxes. The ability to etch names, dates, or custom designs adds a unique touch that resonates with consumers.

Industrial Use: In the industrial sector, yeti laser engraving machines are employed for tasks like marking serial numbers, barcodes, and logos on products. This ensures traceability and branding consistency across different batches.

Art and Craft: Artists and craftspeople love yeti laser engraving for its ability to create intricate patterns and designs on a variety of materials, including wood, glass, and metal. The precision allows for detailed artwork that would be difficult or impossible to achieve with traditional methods.

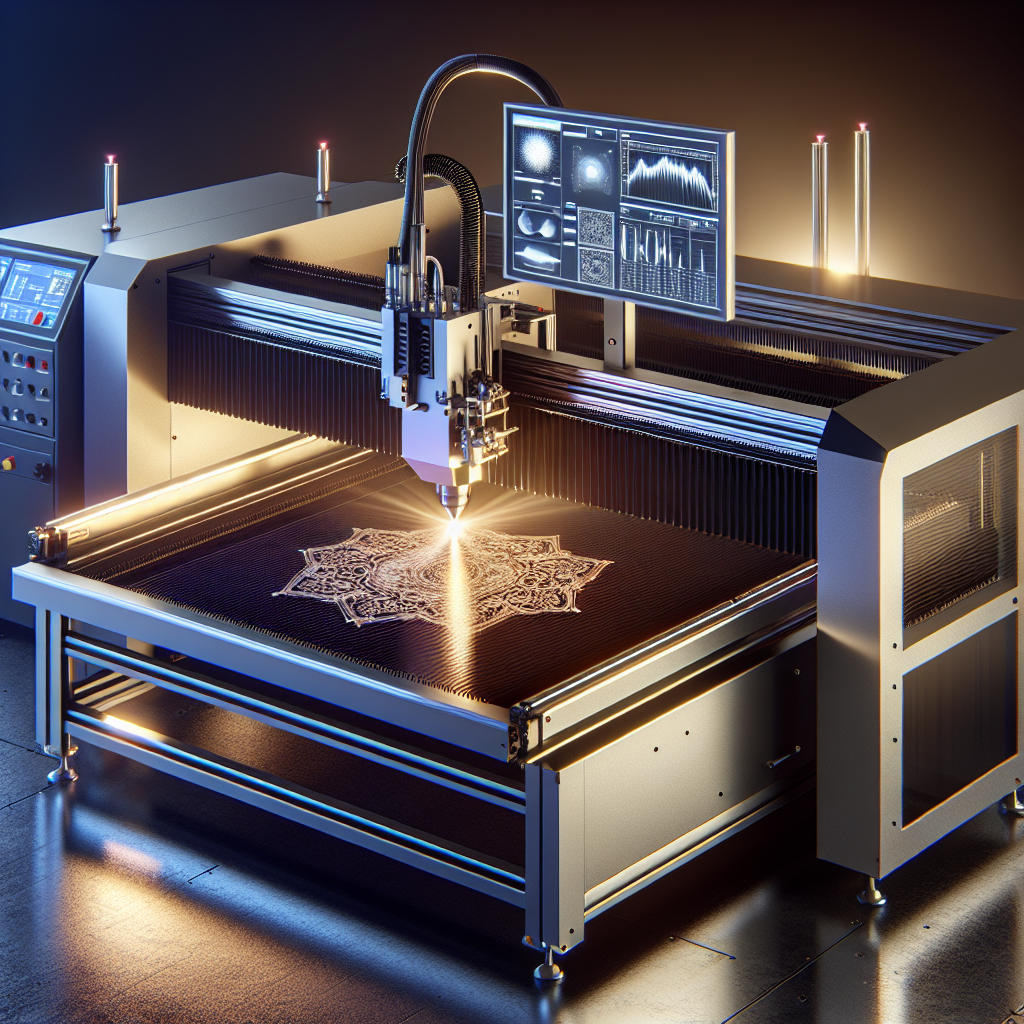

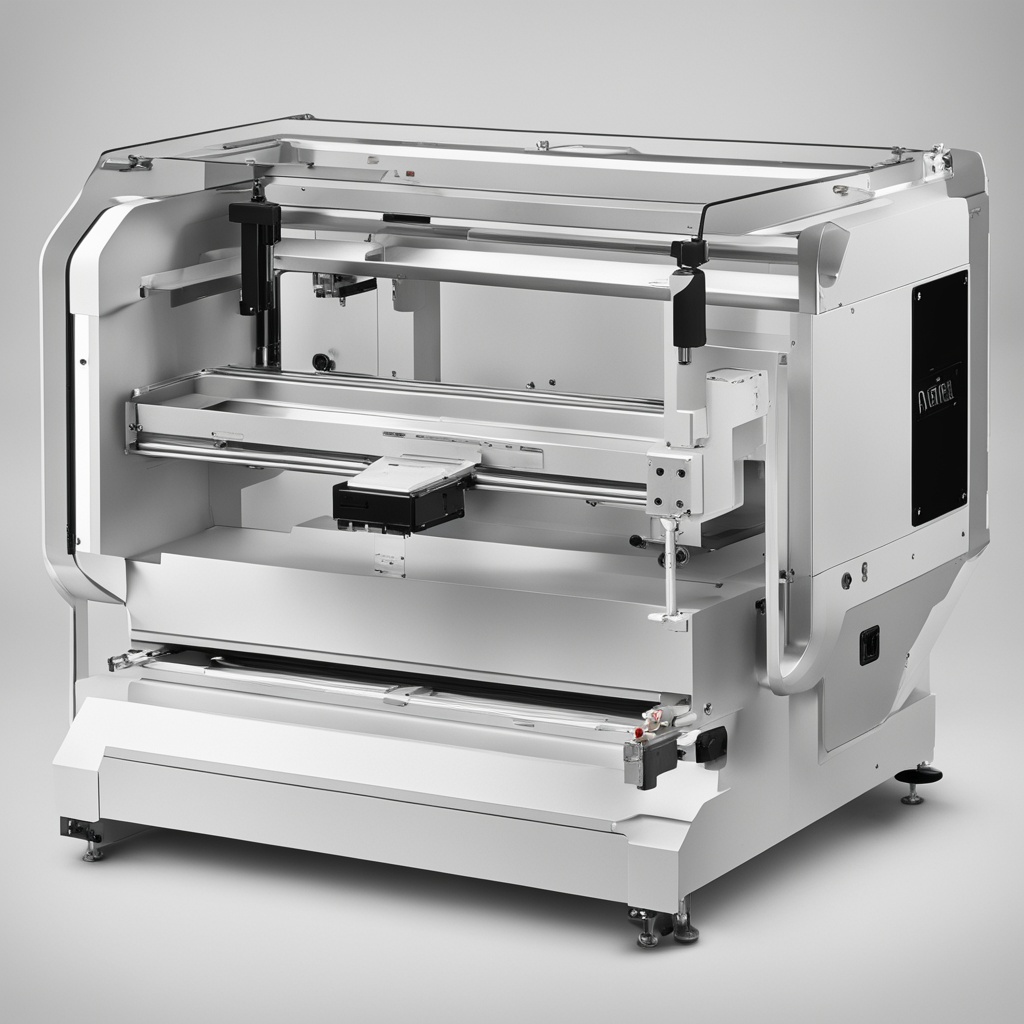

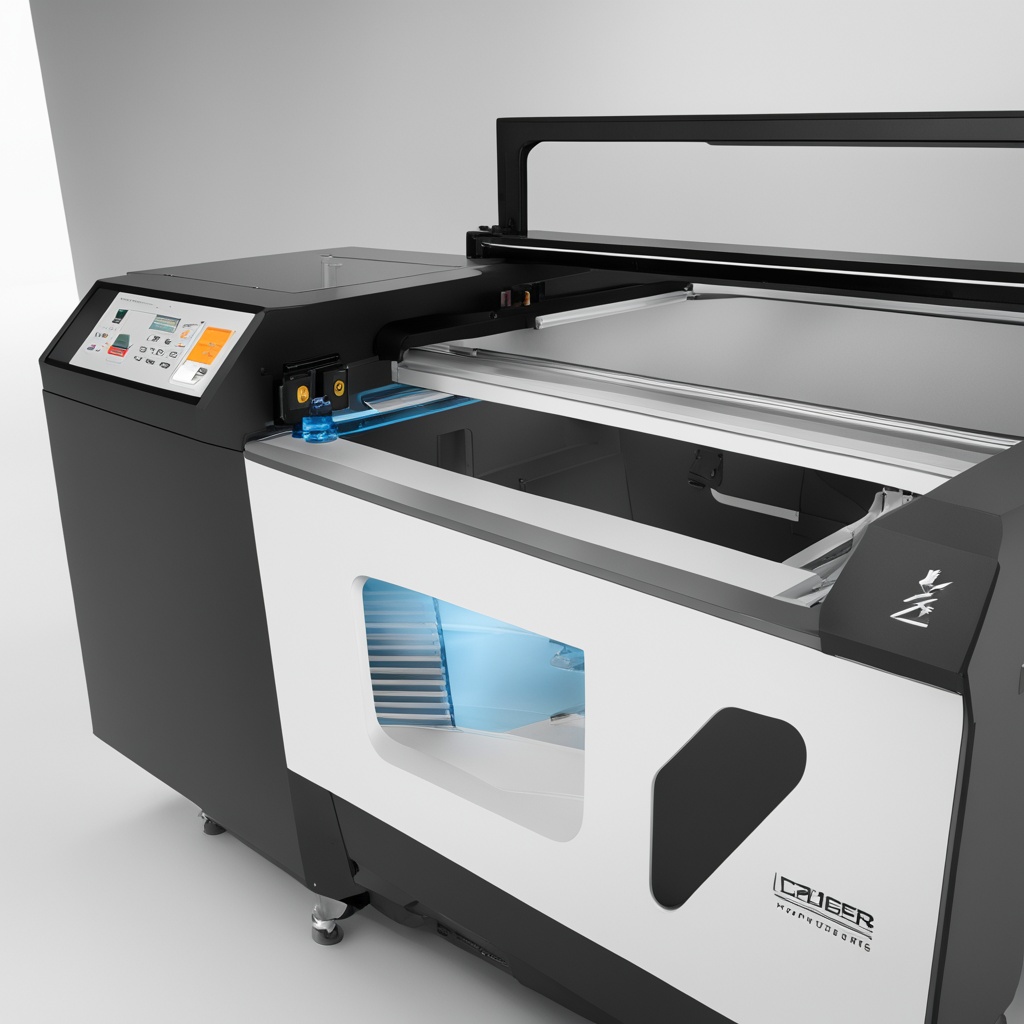

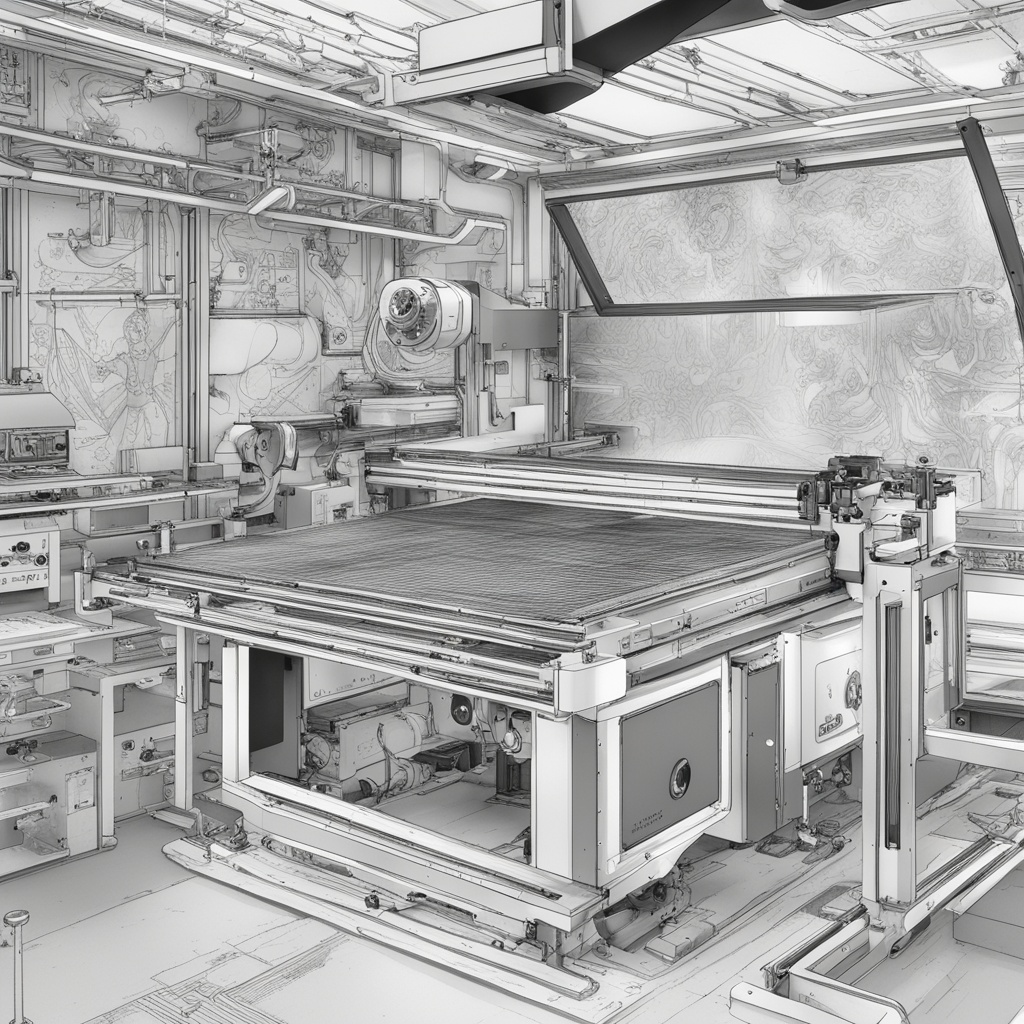

Machine Specifications and Features

Yeti laser engraving machines come in various models tailored to different needs and budgets. Key specifications to consider include:

- Laser Power: The power of the laser beam determines the speed and depth of engraving. Higher-power machines can handle thicker materials and faster engraving speeds.

- Working Area: The size of the workspace dictates the maximum dimensions of the items you can engrave. For larger projects, a machine with a more extensive working area is essential.

- Software Compatibility: User-friendly software is crucial for designing and controlling the laser engraving process. Yeti laser engraving machines typically come with intuitive software that supports a wide range of file formats.

Advanced features such as autofocus, built-in cameras for alignment, and air assist systems (which help clear debris during engraving) further enhance the functionality and precision of yeti laser engraving machines.

Material Compatibility

One of the strengths of yeti laser engraving technology is its versatility in terms of material compatibility. These machines can engrave on:

- Wood: A popular choice for signs, plaques, and decorative items.

- Metal: Ideal for branding, serial numbering, and creating intricate designs on jewelry and tools.

- Glass and Ceramics: Perfect for awards, trophies, and custom art pieces.

- Plastics and Acrylics: Suitable for signs, prototypes, and personalized items.

- Leather and Fabrics: Excellent for personalized gifts and fashion accessories.

The ability to work with such a diverse range of materials makes yeti laser engraving machines a valuable addition to any creative workspace or industrial setting.

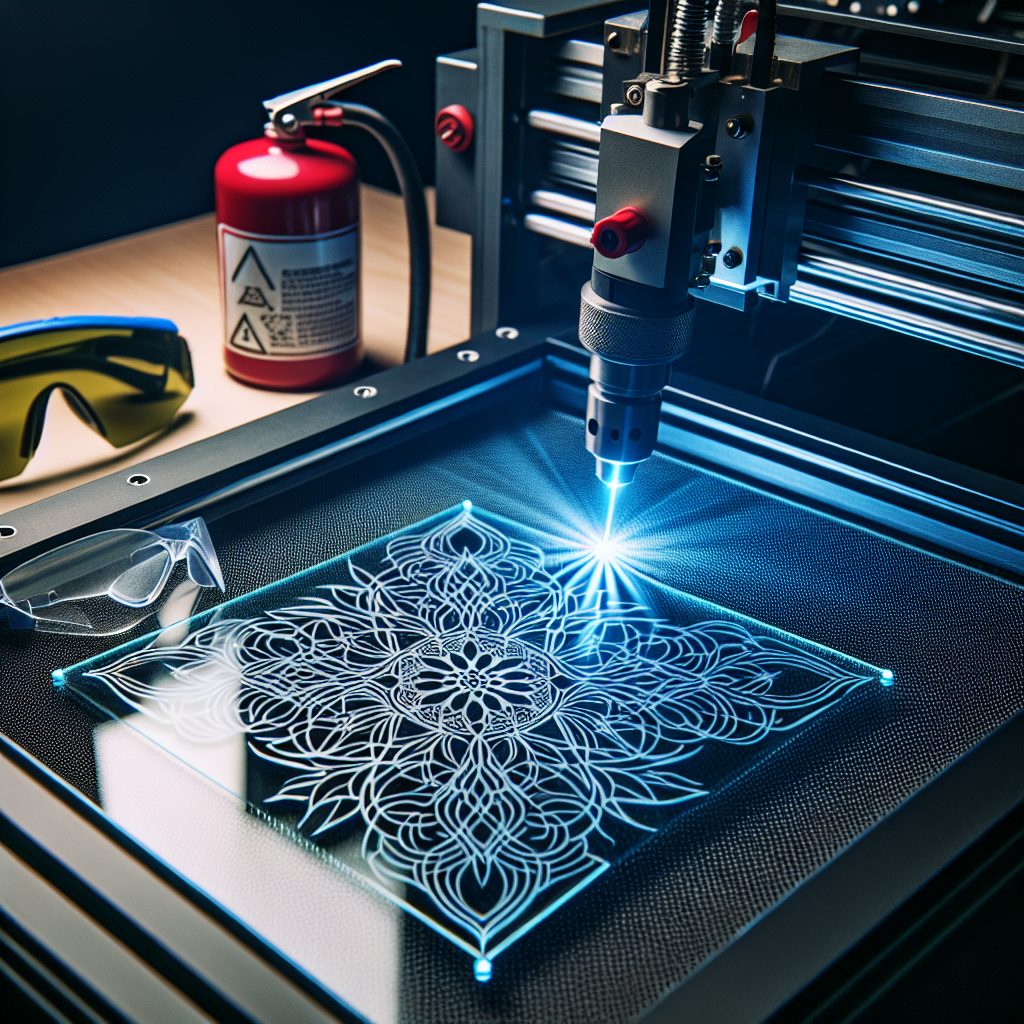

Safety Considerations

Safety is paramount when working with laser engraving machines. Yeti laser engraving machines come with various safety features, but users must also adhere to best practices:

- Eye Protection: Always wear laser-safe glasses when operating the machine or handling laser-etched materials.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of smoke and debris.

- Fire Precautions: Keep flammable materials away from the laser and have a fire extinguisher handy.

- Training: Thoroughly train all operators on the machine’s safety features and emergency shutdown procedures.

Regular safety audits and adhering to the manufacturer’s guidelines are essential for maintaining a safe working environment.

Industry Best Practices

To get the most out of your yeti laser engraving machine, follow these industry best practices:

- Material Preparation: Ensure materials are clean, flat, and properly secured to prevent movement during engraving.

- Regular Maintenance: Keep the machine clean and lubricate moving parts as recommended by the manufacturer.

- Software Proficiency: Familiarize yourself with the software’s features to streamline design and engraving workflows.

By adhering to these practices, you can maximize the efficiency, precision, and lifespan of your yeti laser engraving machine.

Cost-Benefit Analysis

Investing in a yeti laser engraving machine can be a significant expenditure, but it offers numerous benefits that justify the cost:

- Versatility: The ability to engrave on a wide range of materials means you can cater to diverse customer needs.

- Precision: The high level of detail achievable with laser engraving sets your work apart from competitors.

- Efficiency: Laser engraving is faster and more consistent than manual methods, allowing you to take on more projects.

Moreover, the long-term durability and low maintenance requirements of yeti laser engraving machines mean your initial investment will pay off over time.

Maintenance Tips

Proper maintenance is crucial for keeping your yeti laser engraving machine in top condition. Here are some essential tips:

- Clean the Lens: Regularly clean the laser lens with a lint-free cloth and lens cleaner to ensure optimal beam quality.

- Lubricate Moving Parts

- Check Belts and Pulleys: Inspect belts and pulleys regularly for signs of wear or damage and replace them as needed.

- Align the Laser Beam: Periodically check and adjust the laser beam alignment to maintain precision.

- Software

: Use high-quality lubricants to keep moving parts operating smoothly and reduce wear and tear.