Free Software for Laser Engraving: Enhancing Creativity and Efficiency

Laser engraving technology has revolutionized the world of design, art, and manufacturing. With its precision, versatility, and ability to create intricate details on a wide range of materials, laser engraving machines have become indispensable tools in various industries. However, the cost of software can sometimes be a barrier for those looking to explore this fascinating technology. Fortunately, there are several free software for laser engraving options available that can help you unleash your creativity without breaking the bank.

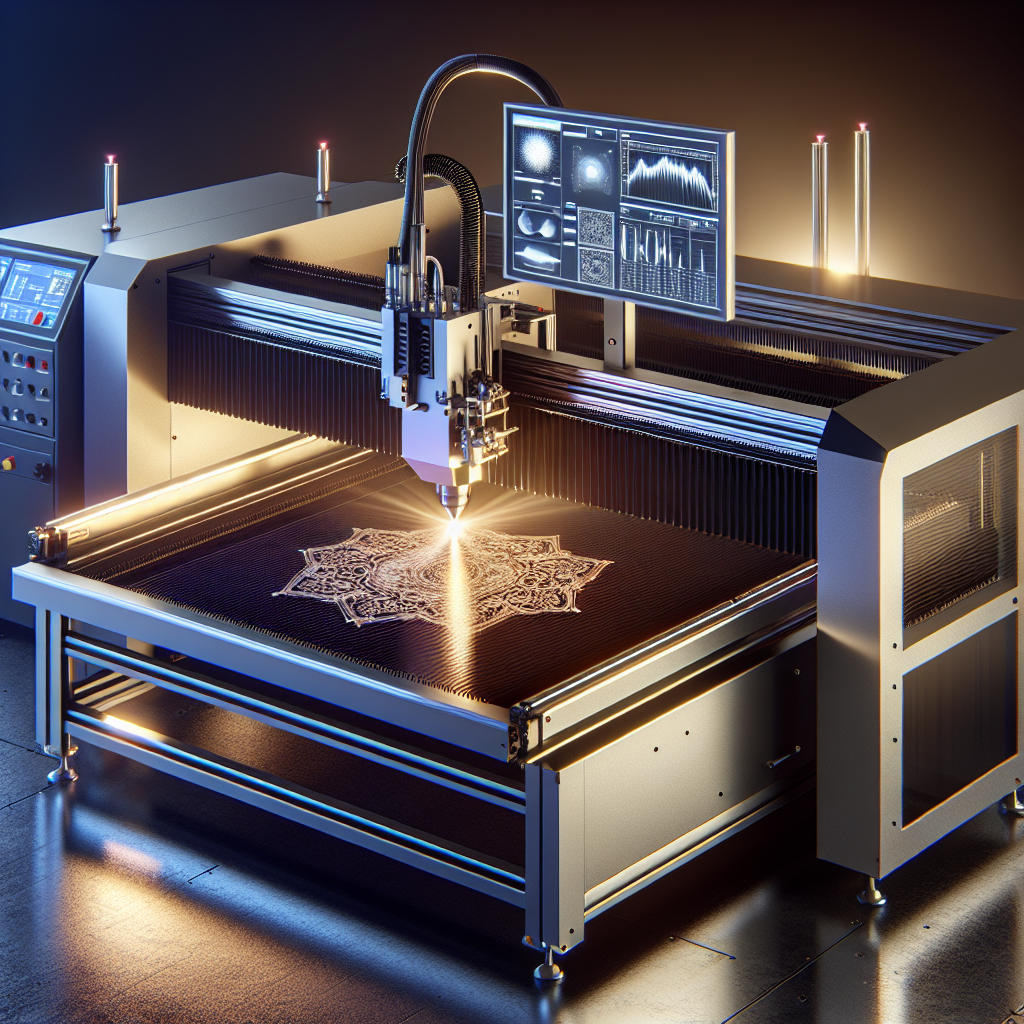

Laser Engraving Technology and Applications

Laser engraving involves using a high-powered laser beam to create designs or text on the surface of a material. This process can be used on a variety of materials, including wood, metal, glass, plastics, and even leather. The precision and detail achievable with laser engraving make it ideal for a wide range of applications, such as personalized gifts, branding, signage, and prototyping.

One of the most significant advantages of laser engraving is its ability to produce high-quality results with minimal waste. Unlike traditional engraving methods, which often require significant amounts of material removal, laser engraving uses a focused laser beam to vaporize the material’s surface, leaving a clean and precise mark. This makes it an environmentally friendly and cost-effective solution for many businesses and individuals.

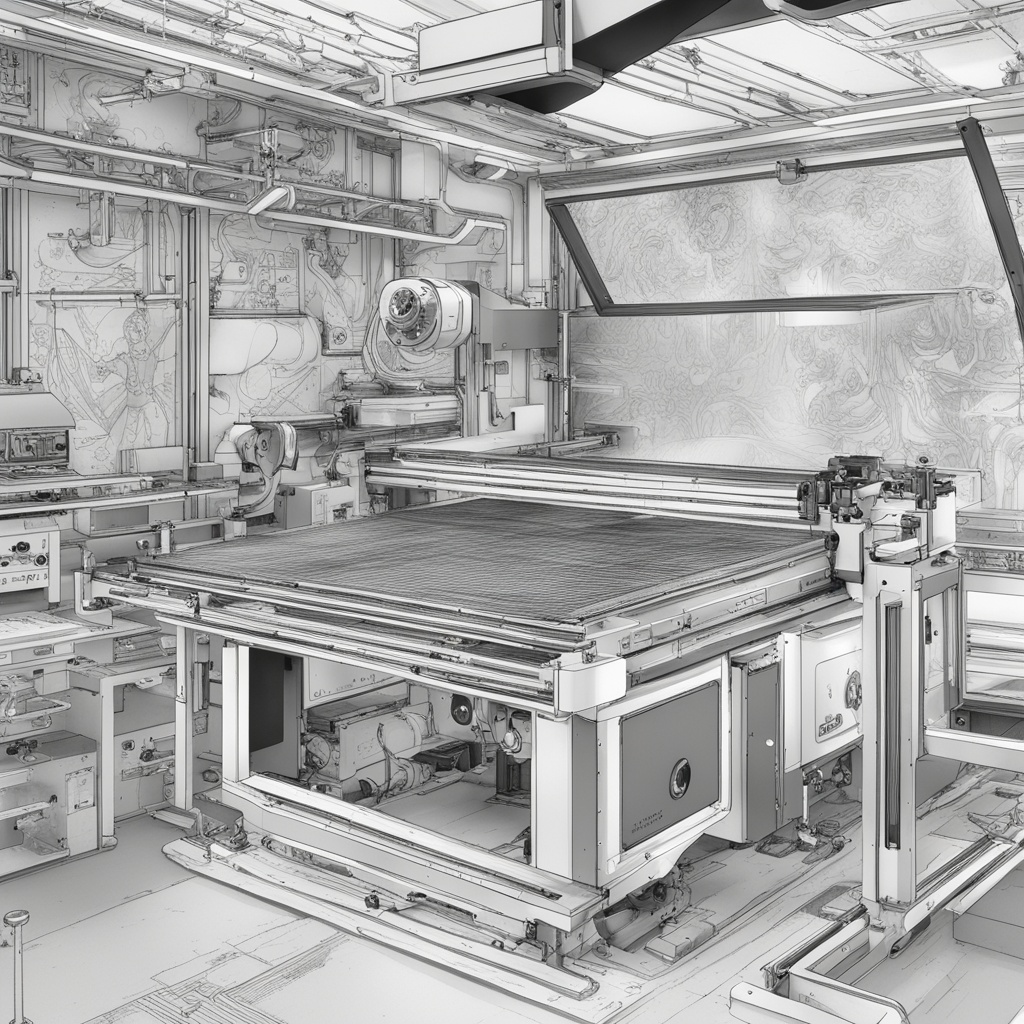

Machine Specifications and Features

When choosing a laser engraving machine, it’s important to consider its specifications and features. Key factors to look for include the laser’s power, wavelength, and beam size, as these will determine the machine’s capabilities and the types of materials it can process.

- Laser Power: The higher the laser power, the faster and deeper the engraving process will be. Machines with more powerful lasers can also handle thicker materials and more intricate designs.

- Wavelength: Different materials absorb light at different wavelengths. Some laser engraving machines offer multiple wavelength options to accommodate a wider range of materials.

- Beam Size: The beam size affects the resolution of the engraved image. A smaller beam size will produce finer details, while a larger beam size is better suited for larger designs and faster processing speeds.

In addition to these specifications, other important features to consider include the machine’s working area, resolution, and compatibility with different file formats. Many modern laser engraving machines also come with built-in software that makes it easy to design and execute projects.

Material Compatibility

Laser engraving machines can be used on a wide range of materials, but not all materials are compatible with all machines. The compatibility of a material with a laser engraving machine depends on factors such as its melting point, absorptivity, and thermal conductivity.

- Wood: Wood is a popular choice for laser engraving due to its absorbency and the fact that it produces a natural, rustic look when engraved.

- Metal: Metals such as stainless steel, aluminum, and brass can be engraved with a laser, but they require higher power levels and may produce a reflective surface that can damage the laser beam.

- Glass: Glass can be etched with a laser to create a frosted or etched effect. However, it requires precise control of the laser’s power and speed to avoid cracking.

- Plastics: Plastics are another versatile material that can be engraved with a laser. Different types of plastics have different melting points and absorptivity levels, so it’s important to choose the right type for your project.

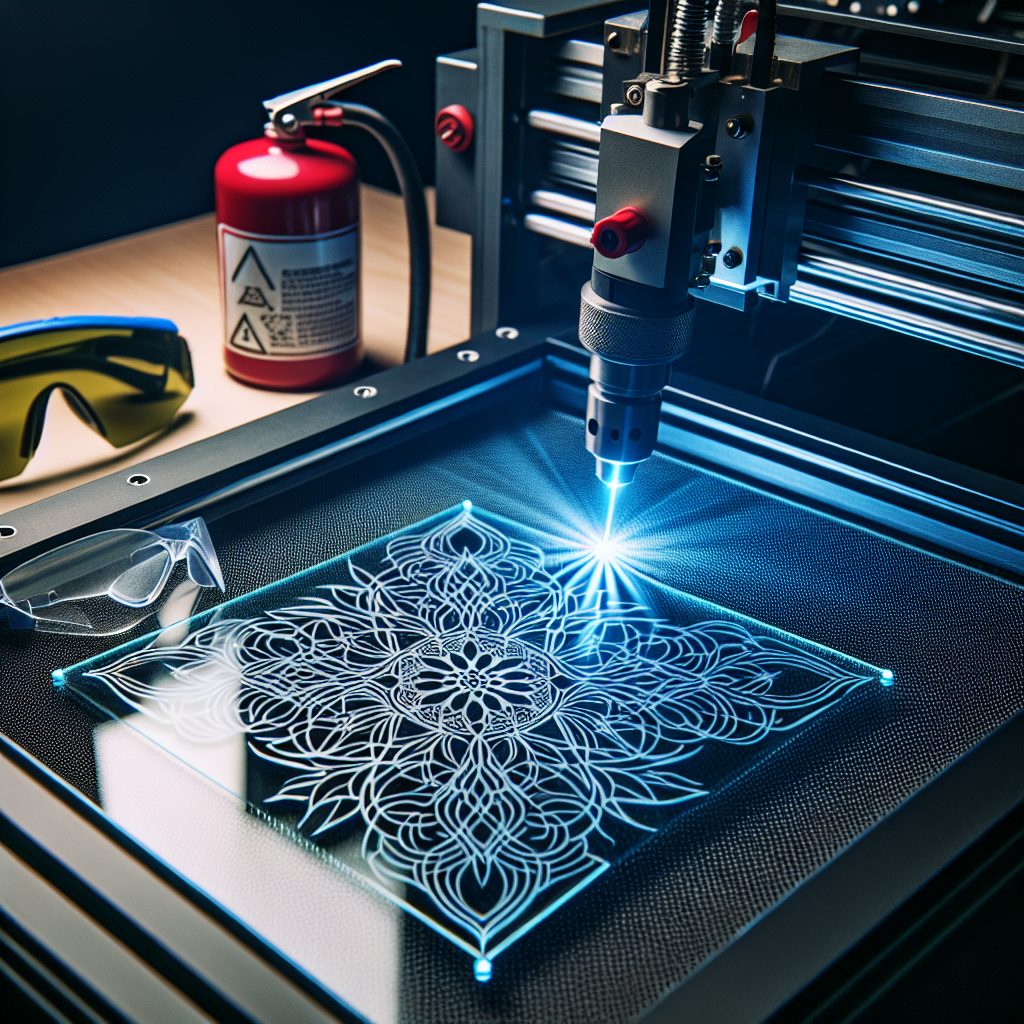

Safety Considerations

Laser engraving machines can be dangerous if not used properly. Safety considerations are crucial to prevent injuries and damage to the machine and surrounding area.

- Eye Protection: Laser beams can cause serious eye damage. Always wear protective eyewear when operating a laser engraving machine.

- Ventilation: Laser engraving produces fumes and particles that can be harmful if inhaled. Ensure the workspace is well-ventilated or use a respirator to protect your lungs.

- Fire Hazards: Laser beams can ignite flammable materials. Keep the workspace free of any combustible materials and have a fire extinguisher on hand.

- Machine Guards: Never operate the machine with the guards removed. These guards are designed to protect the operator from direct contact with the laser beam.

Industry Best Practices

To get the best results from your laser engraving machine, it’s important to follow industry best practices. This includes using the right settings for the material you’re working with, regularly cleaning and maintaining the machine, and staying up-to-date with the latest software and techniques.

- Material Preparation: Ensure the material is clean, flat, and securely clamped before starting the engraving process.

- Testing: Always perform a test run on a scrap piece of material before starting your project to ensure the settings are correct.

- Software Updates: Keep your software up-to-date to benefit from the latest features and bug fixes.

- Training: Invest in training for your team to ensure they are proficient in using the machine safely and effectively.

Cost-Benefit Analysis

When considering the cost of a laser engraving machine, it’s important to weigh the benefits against the initial investment. While high-end machines can be expensive, they offer superior performance and versatility, making them a worthwhile investment for businesses that rely on laser engraving for their operations.

For individuals or small businesses with limited budgets, free software for laser engraving can be a cost-effective solution. These software options typically have a wide range of features and capabilities, allowing users to create professional-quality designs without spending a fortune.

In addition to the cost of the machine and software, it’s also important to consider the ongoing costs of maintenance and consumables. Regular cleaning and maintenance can extend the lifespan of the machine and reduce the need for expensive repairs. Consumables such as lenses and filters will also need to be replaced periodically.

Maintenance Tips

Proper maintenance is crucial for keeping your laser engraving machine in optimal condition. Here are some tips to help you maintain your machine:

- Regular Cleaning: Clean the machine regularly to remove dust, debris, and residue from the lenses, mirrors, and bed.

- Alignment Checks: Periodically check the alignment of the laser beam to ensure it’s hitting the material correctly.

- Filter Replacement: Replace the air filter regularly to prevent dust and debris from entering the machine.

- Lubrication: Keep moving parts lubricated to reduce friction and wear.

- Software Updates: As mentioned earlier, keeping your software up-to-date is important for optimal performance and security.

Project Ideas and Tutorials

Once you’ve chosen your laser engraving machine and software, it’s time to start creating! Here are some project ideas and tutorials to inspire you:

- Personalized Gifts: Use your laser engraving machine to create personalized gifts such as engraved wooden boxes, photo frames, or keychains.

- Signage: Create custom signs and logos for your business or home using a variety of materials, including wood, metal, and acrylic.

- Jewelry: Laser engraving can add a unique touch to jewelry pieces, such as engraved names or patterns on metal rings or bracelets.

- Prototyping: For designers and engineers, laser engraving can be used to create prototypes of products, allowing for faster iteration and testing.

To get started with your projects, consider taking advantage of online tutorials and resources. There are many websites and forums dedicated to laser engraving that offer step-by-step guides, project ideas, and troubleshooting tips.